Nitraria sibirica fruit total flavonoid extract and preparation method of nitraria sibirica fruit total flavonoid extract

An extraction method and technology of Nitraria japonica, which is applied in the direction of drug combination, pharmaceutical formula, plant raw materials, etc., can solve the problems of high extraction cost, incomplete recovery of organic solvent, low yield of flavonoids, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

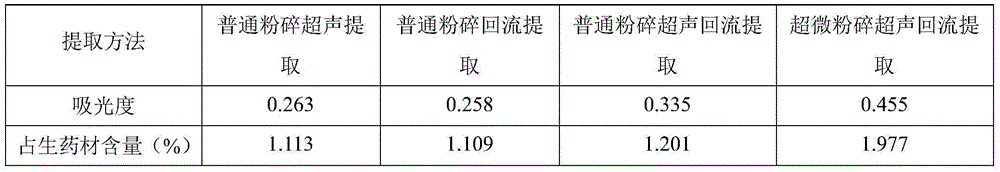

Method used

Image

Examples

Embodiment 1

[0040] 1. Cleaning: Select 10kg of mature Nitraria berries, filter out the sediment, and wash with clean water;

[0041] 2. Drying: Dry the cleaned Nitraria fruit at a low temperature of 15°C for 15 hours;

[0042] 3, crushing: the Nitraria fruit obtained in step 2 is ultrafinely pulverized to obtain Nitraria powder;

[0043] 4. Extraction: Add 5 times the amount of 70% ethanol to the Nitraria powder obtained in step 3 for ultrasonic extraction for 1 hour, stir with a stirrer during this period, obtain filtrate I and filter residue I after filtration, and use filter residue I again for 7 times A large amount of 70% ethanol was refluxed and extracted for 1 h, filtrate II and filter residue II were obtained after filtration, filtrate I and filtrate II were combined, concentrated under reduced pressure to obtain the crude extraction part of total flavonoids of Nitraria japonica;

[0044] 5. Purification: Pack the pretreated polyamide into a column by wet method, take the above c...

Embodiment 2

[0047]1. Cleaning: Select 10kg of mature Nitraria berries, filter out the sediment, and wash with clean water;

[0048] 2. Drying: Dry the cleaned Nitraria fruit at a low temperature of 20°C for 15 hours;

[0049] 3, crushing: the Nitraria fruit obtained in step 2 is ultrafinely pulverized to obtain Nitraria powder;

[0050] 4. Extraction: Add 8 times the amount of 70% ethanol to the Nitraria powder obtained in step 3 for ultrasonic extraction for 1 hour, stir with a stirrer during this period, obtain filtrate I and filter residue I after filtration, and use filter residue I again for 6 times A large amount of 80% ethanol was refluxed and extracted for 1 hour, and the filtrate II and filter residue II were obtained after filtration, the filtrate I and the filtrate II were combined, and concentrated under reduced pressure to obtain the crude extraction part of the total flavonoids of Nitraria japonica;

[0051] 5. Purification: Wet-pack the pretreated polyamide column, take th...

Embodiment 3

[0054] 1. Cleaning: Select 10kg of mature Nitraria berries, filter out the sediment, and wash with clean water;

[0055] 2. Drying: Dry the cleaned Nitraria fruit at a low temperature of 15°C for 20 hours;

[0056] 3, crushing: the Nitraria fruit obtained in step 2 is ultrafinely pulverized to obtain Nitraria powder;

[0057] 4. Extraction: Add 5 times the amount of 70% ethanol to the Nitraria powder obtained in step 3 for ultrasonic extraction for 1.5 hours, stir with a stirrer during this period, obtain filtrate I and filter residue I after filtration, and use filter residue I again for 7 Doubling the amount of 65% ethanol for reflux extraction for 1.5 h, after filtration to obtain filtrate II and filter residue II, combine filtrate I and filtrate II, and concentrate under reduced pressure to obtain the crude extract of total flavonoids from Nitraria japonica;

[0058] 5. Purification: Wet packed the pretreated Nylon polyamide column, took the above crude extract and loaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com