Pulsating flow-based oscillating jet type micro-mixer

A micro-mixer and jet technology, which is applied in the fields of chemical industry and life science, can solve the problems of difficult processing and single mixing mechanism of the micro-mixer, and achieve the effects of improving mixing efficiency, easy structure and high mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Processing requirements

[0027] a) The material of this kind of micro-mixer is made of glass material, PDMS and other transparent materials, and the processing method adopts the method of chemical etching. The external conduits at the entrance and exit of the channel can use Teflon plastic hose. Pay attention to the bonding quality between the glass plate and the underlying substrate to ensure the hermeticity of the system.

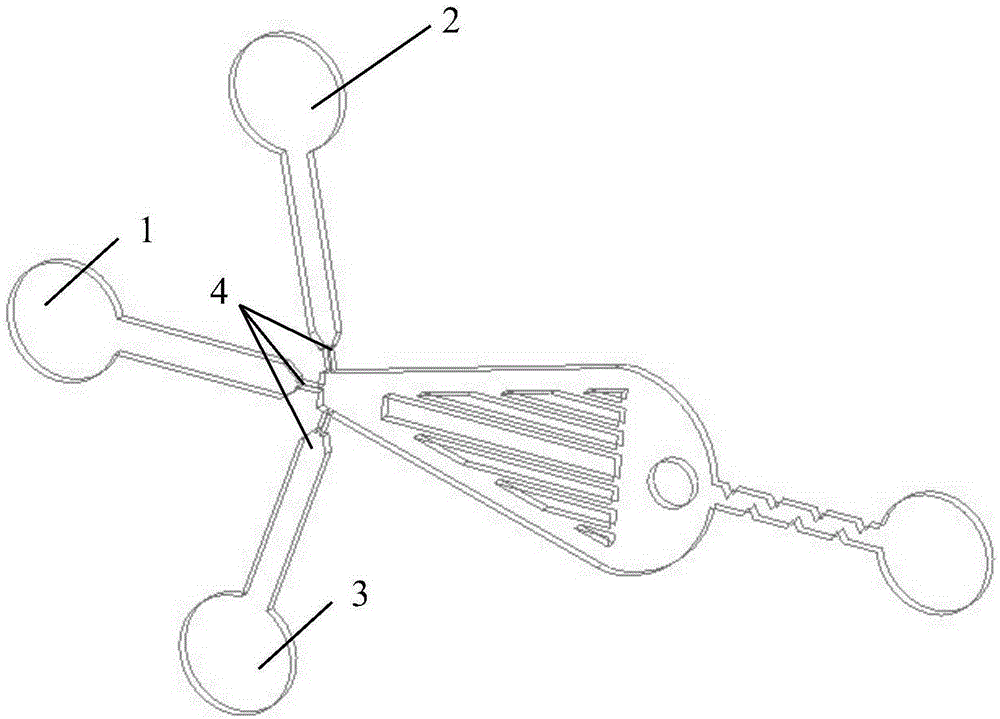

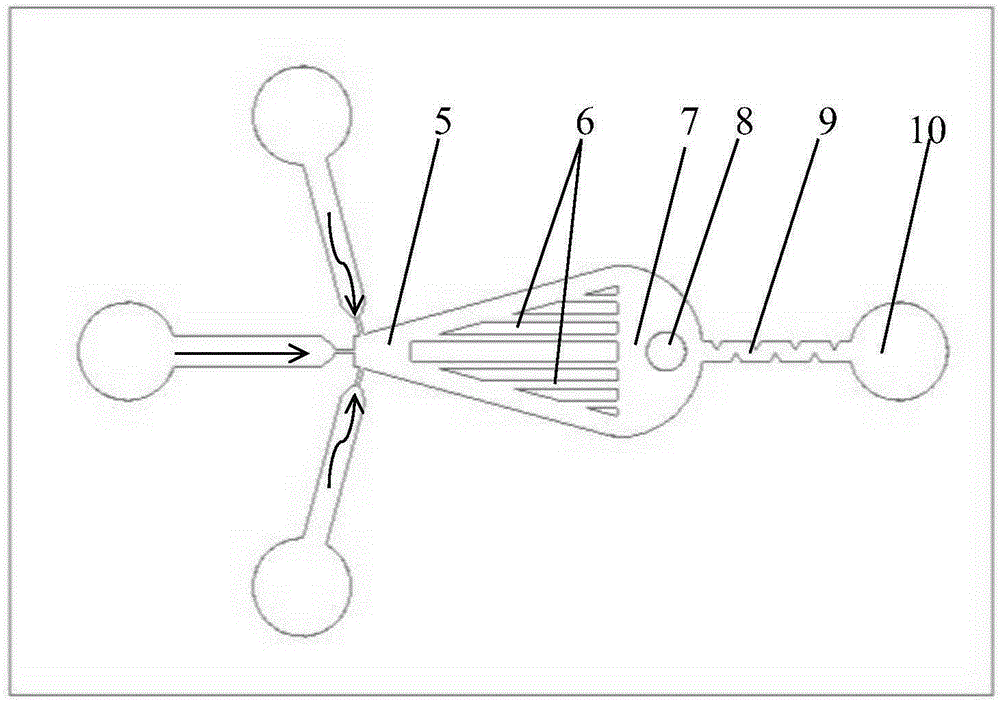

[0028] b) This kind of micro-mixer can realize the mixing of various fluids, and multiple inlet channels can be provided, and only three inlet channels are provided for the convenience of explanation in the text. Therefore, if it is necessary to increase the mixing number of fluid types in actual design, a branch structure can be added at the inlet channel a(1) to meet the requirements of actual working conditions.

[0029] c) The width of the inlet channel b(2), the inlet channel c(3) and the inflow angle can be changed according to the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com