Preparing and testing method of medium-low-temperature loaded denitration catalyst taking raw iron ore as carrier

A denitration catalyst, iron ore technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as narrow active temperature window and poor low temperature activity , to achieve the effect of wide temperature window, high low temperature activity and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

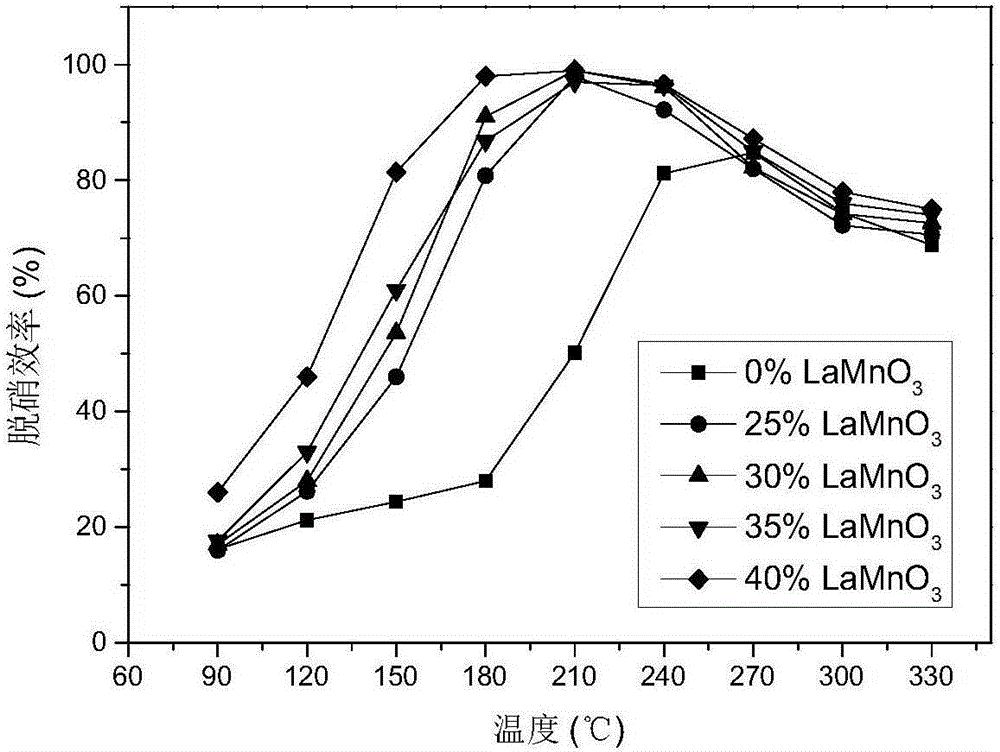

[0031] The active material loading is 40% LaMnO 3 The preparation method steps of the low-temperature denitration catalyst of hematite are as follows:

[0032] Firstly, the hematite is crushed mechanically, and then the iron ore particles of 35-65 mesh are screened out, and then preheated at 320°C to obtain the hematite carrier; at the same time, 0.04molLa (NO 3 ) 3 ·nH 2 O, 0.04molMn (NO 3 ) 2、 0.08molC 6 h 8 o 7 ·6H 2O, put it into the beaker that has measured 50ml of deionized water successively, prepare the solution according to the ratio of 1:1:2, put it on the constant temperature magnetic stone stirrer, first stir and heat it in a water bath at 30°C for 0.5h , then weigh 24.2g of the previously obtained hematite (limonite) carrier, put it into the newly prepared solution, and then adjust the temperature of the constant temperature magnet stirrer to 80°C, stir and heat in a constant temperature water bath until the solvent evaporates Then transfer it to an oven ...

Embodiment 2

[0034] Implementation steps are as example 1, other conditions are constant, change carrier hematite amount to be 27.66g, make active material loading capacity be 35%LaMnO 3 / Hematite Catalyst.

Embodiment 3

[0036] The implementation steps are as example 1, other conditions are constant, the amount of carrier hematite is changed to 32.26g, and the obtained active material load is 30%LaMnO 3 / Hematite Catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com