Laser scan filling system and scan filling method thereof

A laser scanning and filling system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of slow filling scanning speed and insufficient scanning accuracy, and achieve improved scanning efficiency and accuracy, high scanning accuracy and efficiency. and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

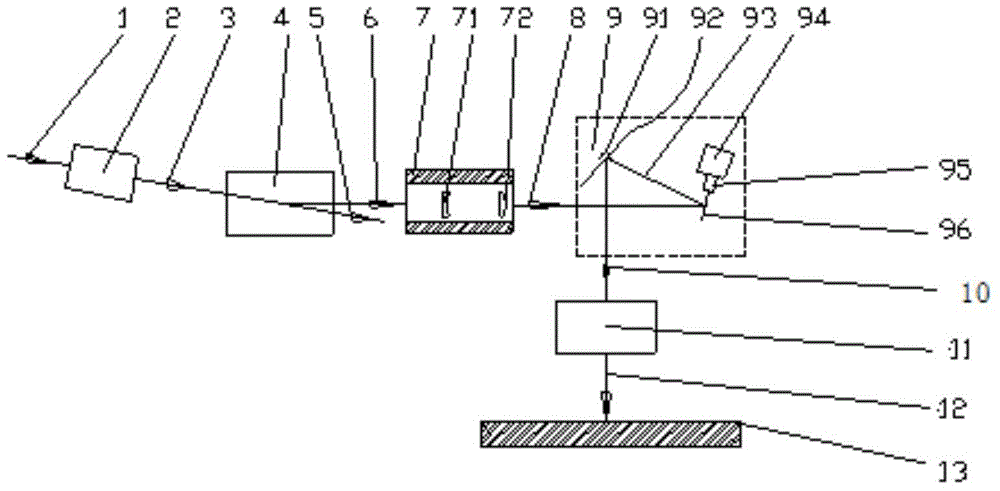

[0046] Embodiment 1. A laser scanning filling system. The following combination Figure 1-Figure 4-d The system provided in this embodiment will be described in detail.

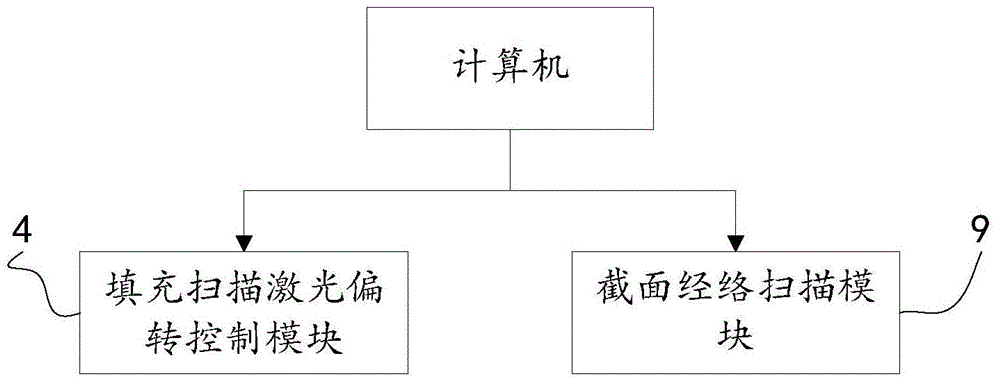

[0047] see figure 1 and figure 2 The system provided in this embodiment includes a computer, a laser focusing module 2 , a filling and scanning laser deflection control module 4 , a beam divergence and expansion optical module 7 , a section meridian scanning module 9 and a laser flat-field focusing module 11 .

[0048] The computer is used to control the real-time scan width range capability of the filling scanning according to the area and shape of the scanning section to be filled and the laser deflection control module 4 for filling and scanning, divide the scanning section to be filled into the filling area, and divide the filling area between two adjacent filling area lines Determine a scanning meridian line between them; it is also used to send the determined filling scanning range information to th...

Embodiment 2

[0067] Embodiment 2, a laser scanning filling system for silicon wafer laser milling blind slots, as shown in Figure 5, the device for silicon wafer laser milling blind slots includes a computer (not shown), laser focusing module 2, filling scanning laser Deflection control module 4 , beam divergence and expansion optical module 7 , section meridian scanning module 9 and laser flat-field focusing module 11 .

[0068] Wherein, the first laser beam 3 is a focused beam, and the filling and scanning laser deflection control module 4 uses piezoelectric ceramics (not shown in the figure) to drive a plane reflector to perform one-dimensional or two-dimensional deflection and reflection on the first laser beam 3. The ability to modulate the reflection of the laser beam at an angle can achieve a frequency of 10KHz or even higher. This very high modulation frequency makes the laser filling and scanning very fast.

[0069] The first laser beam 3 is incident on the piezoelectric ceramic d...

Embodiment 3

[0077] Embodiment 3, a laser scanning filling method. The following combination Figure 6 The method provided in this embodiment is described in detail.

[0078] see Figure 6 , the laser scanning filling method provided in this embodiment includes:

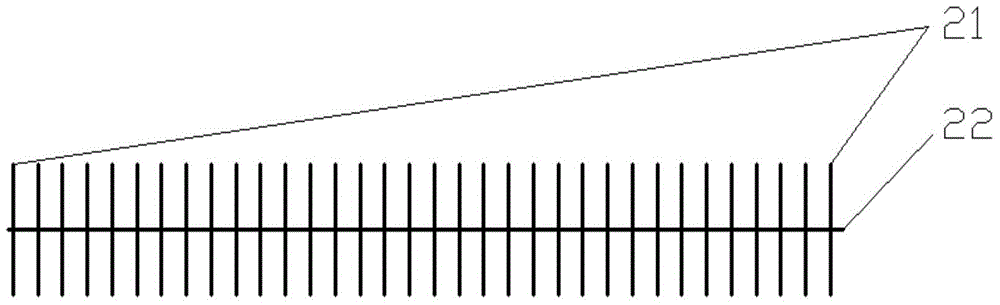

[0079] S1. According to the area and shape of the scanning section to be filled and the laser deflection control module of the filling scanning to control the real-time scanning width range capability of the filling scanning, the computer divides the scanning section to be filled into area lines, and determines a line between two adjacent filling area lines scanning the meridian lines; and sending the filling scanning range information determined according to the filling area lines to the filling scanning laser deflection control module and sending the meridian scanning position information to the section meridian scanning module.

[0080] Specifically, the computer first partitions the filling section to be scanned. When part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com