Rotary immersed water treatment ultra-micro-filtering method and device

A water treatment and immersion technology, applied in the direction of osmosis/dialysis water/sewage treatment, ultrafiltration, chemical instruments and methods, etc., can solve the problems of reduced filtration efficiency, easy blockage of membrane pores, accumulation of pollutants, etc., to achieve Improve filtration efficiency, prevent enrichment, and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

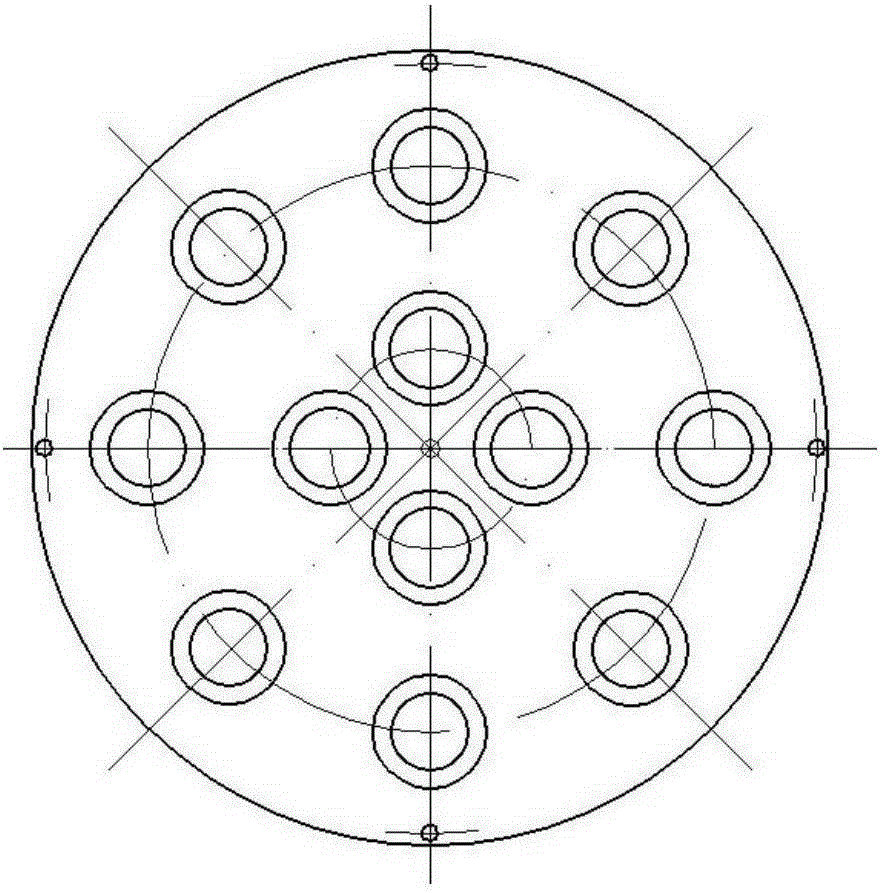

[0021] A rotary immersion ultra-microfiltration method for water treatment, in which no membrane tube is arranged outside the membrane module, so that the membrane filaments are in an open state and directly contact the flowing filtered water. The driving device is used to make the membrane module rotate forward and backward in the water to be treated. During the movement, the water flow and the membrane filaments have relative friction. Because the surface of the membrane filament is subjected to the scouring force (tangential force) of the water flow, the dirt on the surface of the membrane filament is taken away in time. .

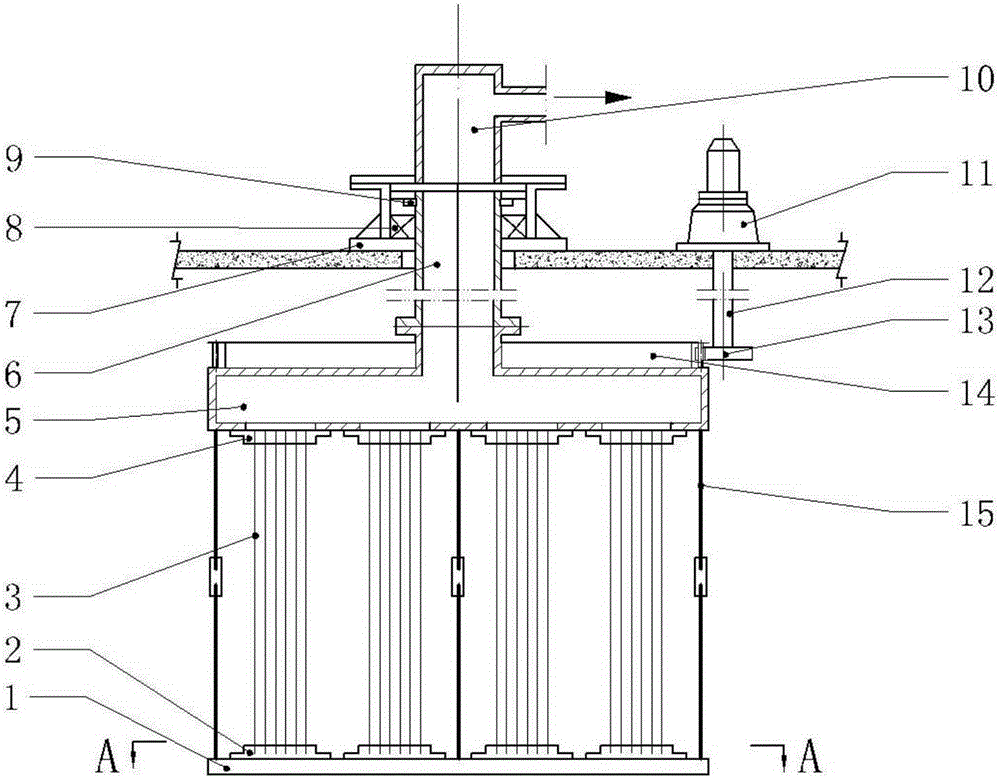

[0022] A rotary submerged ultra-microfiltration device for water treatment, comprising several bundles of membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com