A kind of anti-moon dust material and its application

A dust-proof agent and dust-proof coating technology, applied in the field of materials, can solve the problems of reducing astronauts' workload, wasting astronauts' time, and low removal rate of moon dust, so as to reduce van der Waals force, achieve good dust-proof effect, The effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

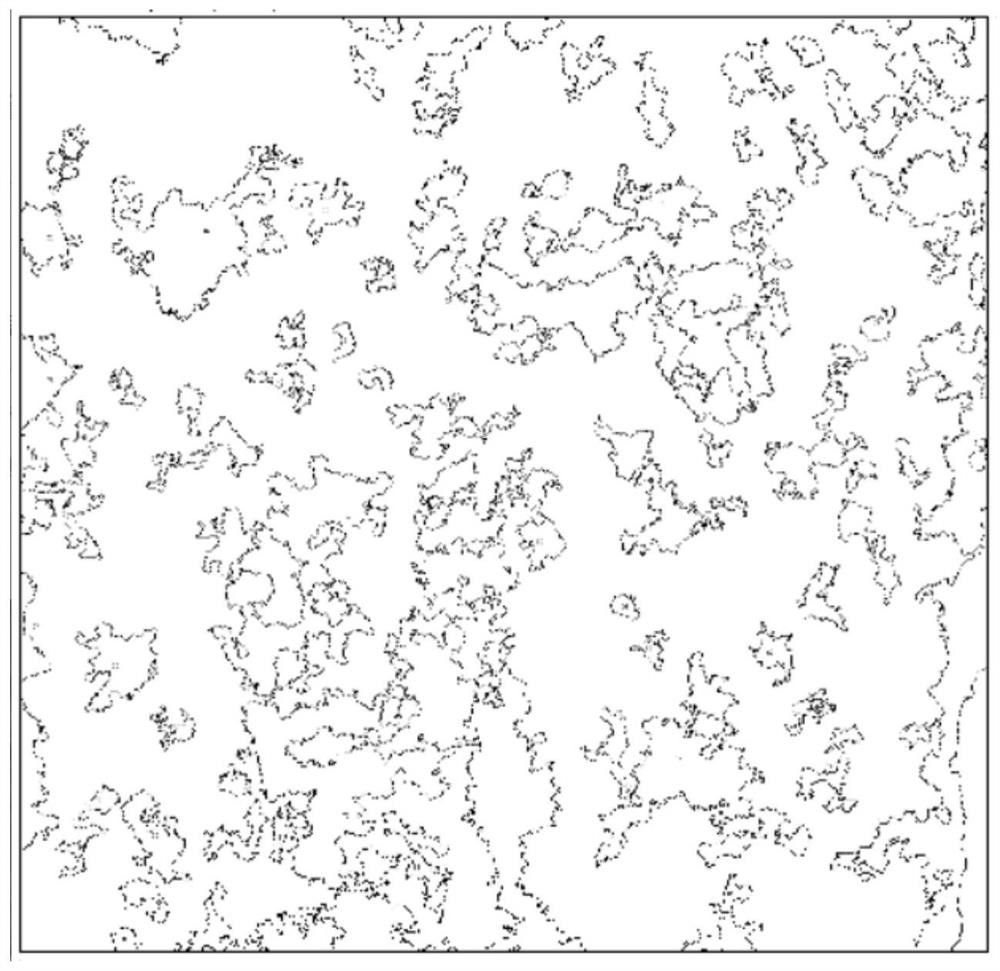

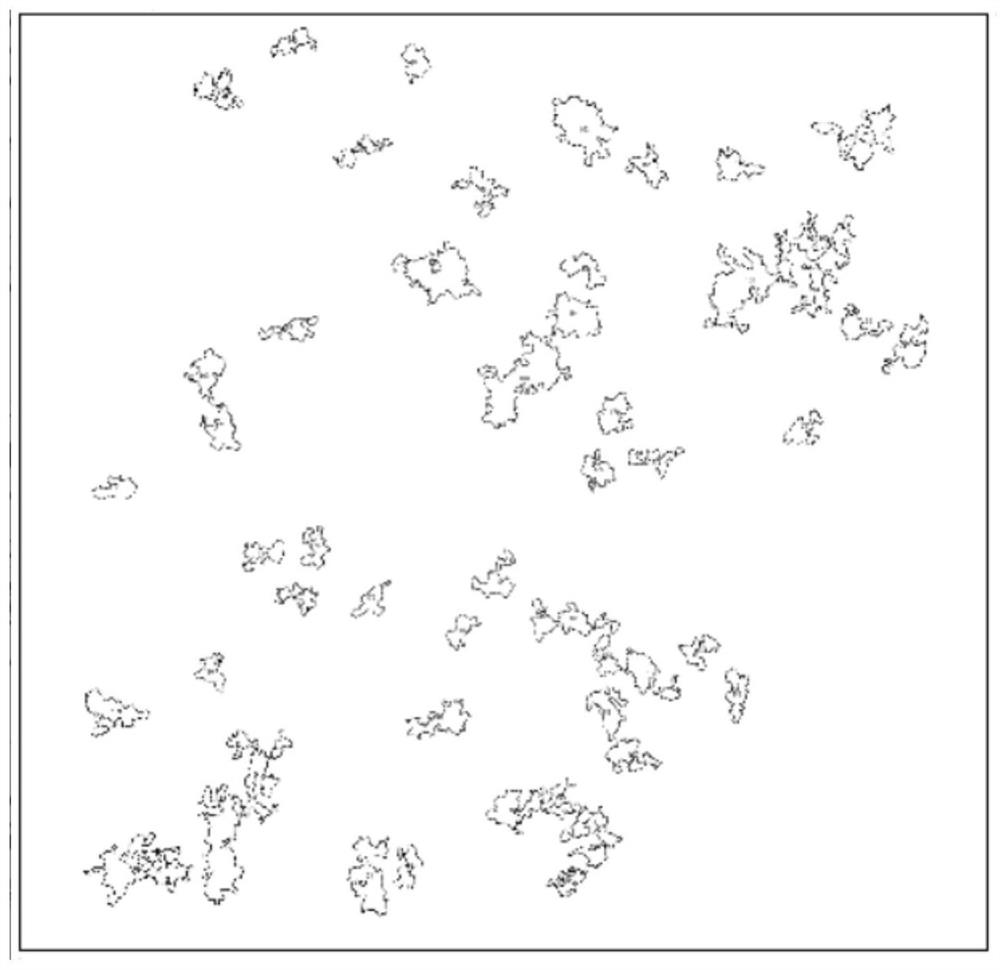

Image

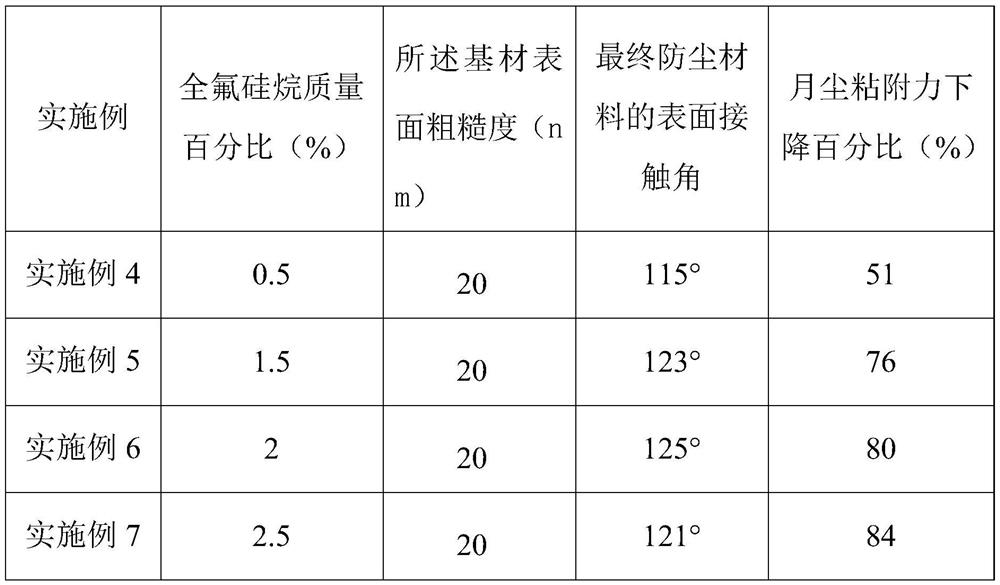

Examples

Embodiment 1

[0049] Preparation of dust-proofing agent

[0050] Step 1. Dissolve 1% perfluorosilane and 2% silane coupling agent in 97% absolute ethanol in proportion, then stir for 40 minutes at a speed of 4000 r / min, and then ultrasonically treat for 10 minutes, and the ultrasonic frequency is 60KHz. Get dust repellant.

[0051] Processing aluminum sheet (pure aluminum sheet)

[0052] S1: The surface of the aluminum sheet is first subjected to mechanical polishing treatment. After that, the mechanically polished aluminum sheet is used as the anode, and the metal copper is used as the cathode. The two electrodes are immersed in a 0.15mol / L sodium chloride solution in the electrolytic cell at the same time, and the direct current is applied. , at 2A / cm 2 Under the current density of 360S, the polished aluminum sheet was obtained by etching for 360S.

[0053] After testing, the surface roughness of the polished aluminum sheet was 20nm. It was dipped in a dust-proof agent, left standing f...

Embodiment 2

[0057] Preparation of dust-proofing agent

[0058] Step 1. Dissolve 3% perfluorosilane and 1% silane coupling agent in 96% absolute ethanol in proportion, then stir for 30 minutes at a speed of 5000r / min, and then ultrasonically treat for 20 minutes, and the ultrasonic frequency is 40KHz. Get dust repellant.

[0059] Processing aluminum sheet (pure aluminum sheet)

[0060] S1: The surface of the aluminum sheet is first subjected to mechanical polishing treatment. After that, the mechanically polished aluminum sheet is used as the anode, and the metal copper is used as the cathode. The two poles are immersed in a 0.5mol / L sodium chloride solution in the electrolytic cell at the same time, and the direct current is applied. , at 1.5A / cm 2 Etching was carried out for 120 s at the same current density to obtain polished aluminum sheets.

[0061] After testing, the surface roughness of the aluminum sheet after polishing is 80nm. It is dipped in a dustproof agent, and after stand...

Embodiment 3

[0063] Preparation of dust-proofing agent

[0064] Step 1. Dissolve 2% perfluorosilane and 2% silane coupling agent in 96% anhydrous ethanol in proportion, then stir for 30min at a speed of 4500r / min, and then ultrasonically treat for 20min, the ultrasonic frequency is 50KHz, Get dust repellant.

[0065] Processing stainless steel sheet (pure stainless steel sheet)

[0066] S1: The surface of the stainless steel sheet is first subjected to mechanical polishing treatment. After that, the mechanically polished stainless steel sheet is used as the anode, and the metal copper is used as the cathode. The two poles are immersed in a 0.2 mol / L sodium chloride solution in the electrolytic cell at the same time, and the direct current is applied. , at 2A / cm 2 Etching was carried out for 300 s under the current density of 100 Å to obtain polished stainless steel sheets.

[0067] After testing, the surface roughness of the stainless steel sheet after polishing was 23nm. It was dipped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com