Dimethyl phosphite production device and dimethyl phosphite production process

A technology for dimethyl phosphite and production equipment, which is applied in the fields of compounds, chemical instruments and methods, organic chemistry, etc. of Group 5/15 elements of the periodic table, and can solve problems such as low yield, long reaction route, and many side reactions. problems, to achieve the effect of improving product purity, increasing product yield, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

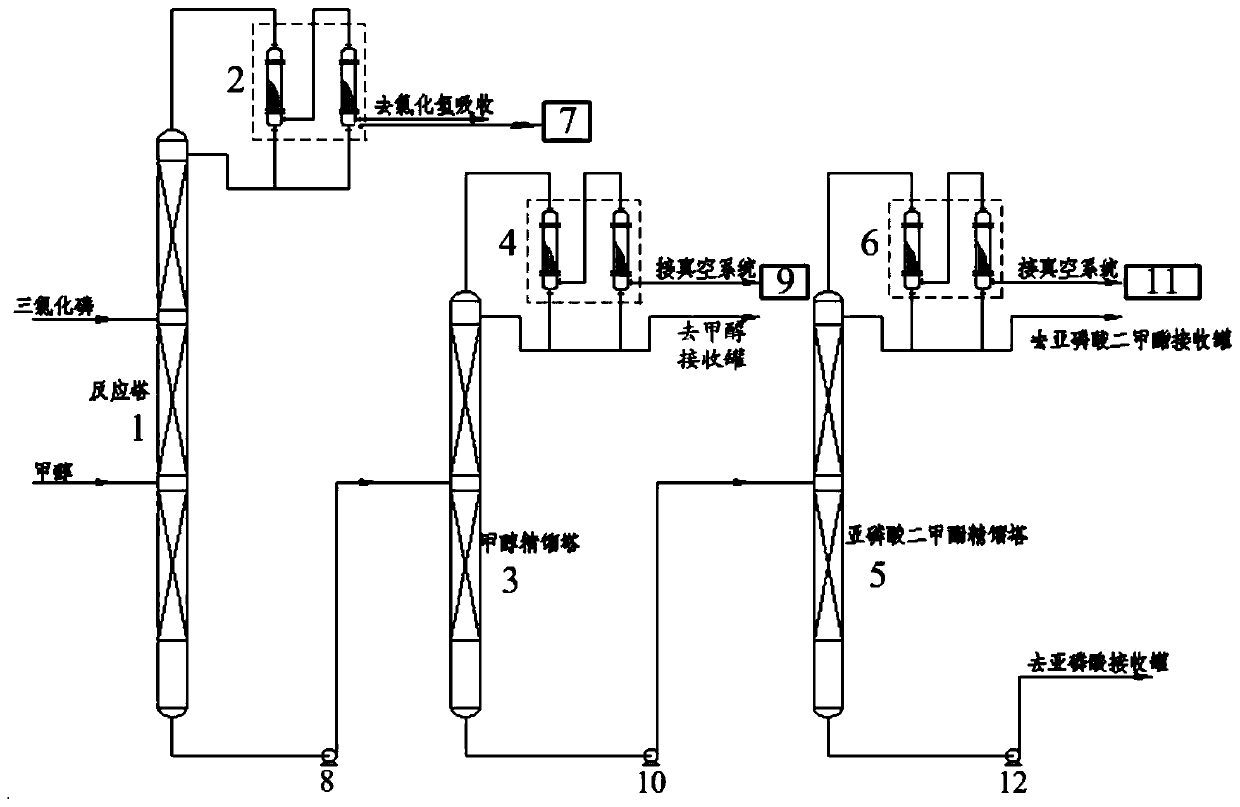

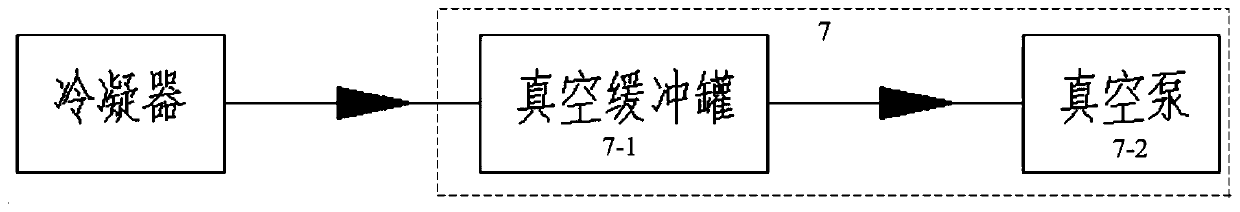

[0111]S1. Add methanol to the bottom of the reaction tower. The amount added is 1 / 2 of the volume of the tower kettle. The refrigerant in the condensation device at the top of the tower is cold brine at -15°C. Turn on the refrigerant circulation system, connect the condensation device to the vacuum system, and turn on the vacuum pump. Make the absolute pressure in the reaction tower be 15KPa, heat the reactor of the reaction tower, and make the inside of the reaction tower reach a state of total reflux.

[0112] S2, phosphorus trichloride and methanol are simultaneously and continuously pumped into the reaction tower with a molar ratio of 3: 1, and the flow regulator on the phosphorus trichloride feed line and the flow regulator on the methanol feed line ensure that the two raw materials are The above molar ratio enters the reaction tower accurately and stably. Wherein, the total number of trays in the reaction tower is 25, the phosphorus trichloride feed port is set at the 12...

Embodiment 2

[0118] S1. Add methanol to the bottom of the reaction tower. The amount added is 1 / 2 of the volume of the tower kettle. The refrigerant in the condensation device at the top of the tower is cold brine at -15°C. Turn on the refrigerant circulation system, connect the condensation device to the vacuum system, and turn on the vacuum pump. The absolute pressure in the reaction tower is 5KPa, and the reactor of the reaction tower is heated to make the inside of the reaction tower reach a state of total reflux.

[0119] S2, phosphorus trichloride and methanol are simultaneously and continuously pumped into the reaction tower with a molar ratio of 3: 1, and the flow regulator on the phosphorus trichloride feed line and the flow regulator on the methanol feed line ensure that the two raw materials are The above molar ratio enters the reaction tower accurately and stably. Wherein, the total number of trays in the reaction tower is 30, the phosphorus trichloride feed port is set at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com