Environment-friendly mine low-temperature spraying material and preparation method thereof

A spraying material and an environmentally friendly technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased dust pollution, foaming agent pollution, poor adhesion, etc., to improve the drainage effect and prevent gas richness The effect of large set and foaming magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

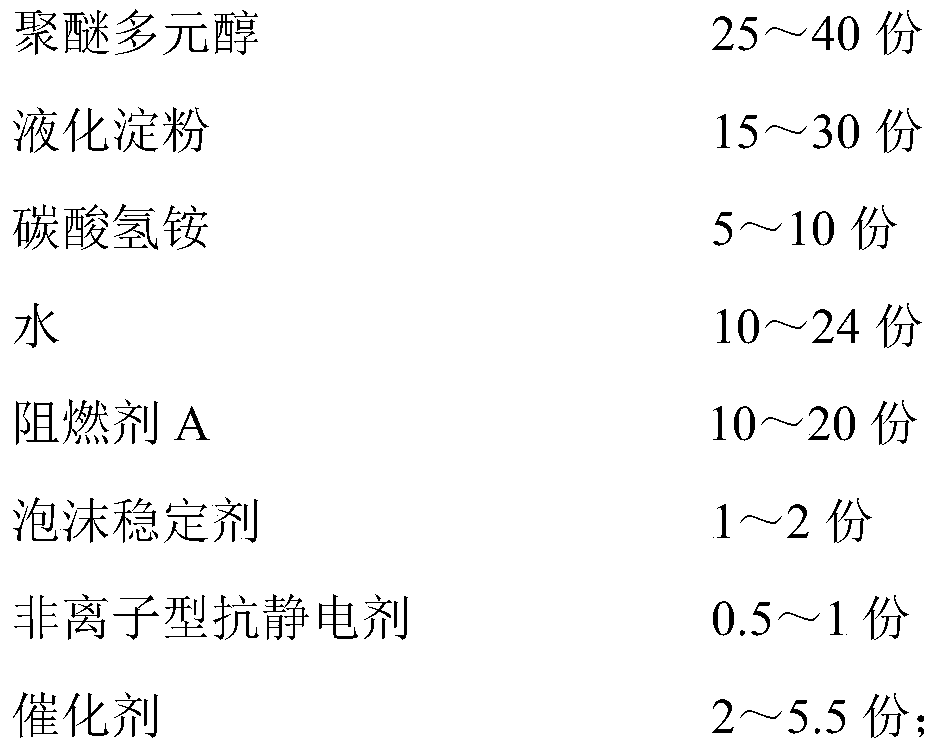

[0029] Component A: Weigh 25 parts of polyether polyol (functionality: 3, molecular weight: 3000), 30 parts of liquefied starch, 10 parts of ammonium bicarbonate, 21 parts of water, 10 parts of tris(2-chloropropyl) phosphate , 1 part of foam stabilizer (B8544, Evonik), 1 part of epoxy adduct of fatty acid, 1 part of bis(dimethylaminoethyl) ether, 0.5 part of pentamethyldiethylenetriamine, tris(two 0.5 parts of methylaminopropyl) hexahydrotriazine are mixed evenly, and packaged for later use;

[0030] Component B: Weigh 70 parts of polymethylene polyphenyl polyisocyanate and 30 parts of tris(2-chloroethyl) phosphate, stir evenly, and package for later use;

[0031] Mixing and curing: Add component A and component B into the spraying machine with a mass ratio of 1:1 for spraying. The performance test results are shown in Table 1.

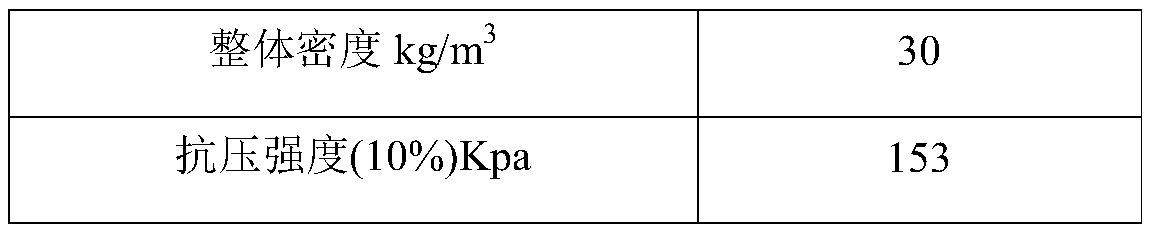

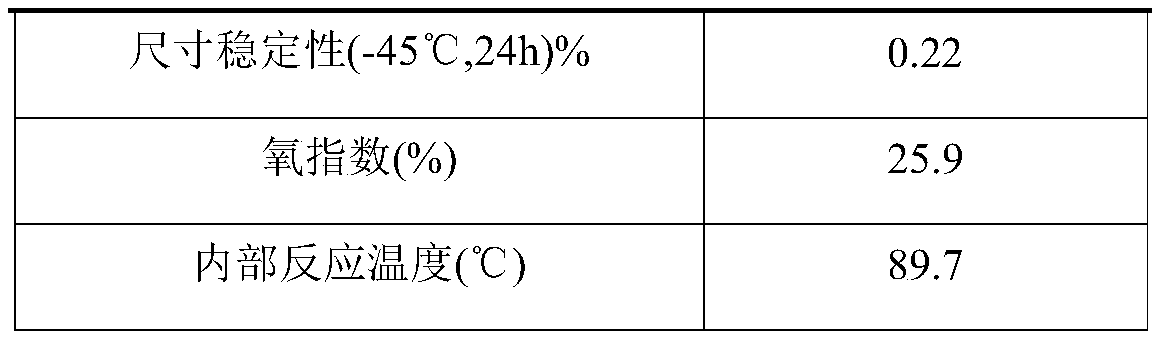

[0032] The product performance testing result that table 1 embodiment 1 obtains

[0033] Overall density kg / m 3

Embodiment 2

[0035] Component A: Weigh 30 parts of polyether polyol (functionality: 3, molecular weight: 2000), 26 parts of liquefied starch, 8 parts of ammonium bicarbonate, 10 parts of water, and 10 parts of tris(2-chloropropyl) phosphate , 10 parts of triethyl phosphate, 2 parts of foam stabilizer (L6869, American Momentive), 0.5 parts of ethanolamine-glycidyl ether and 2 parts of catalyst dimethylcyclohexylamine, tris(dimethylaminopropyl) hexahydrotri 1.5 parts of oxazine were mixed evenly, and packaged for later use;

[0036] Component B: Weigh 60 parts of polymethylene polyphenyl polyisocyanate, 30 parts of carbodiimide modified isocyanate, and 10 parts of dimethyl methylphosphonate, stir evenly, and package for later use;

[0037] Mixing and curing: Add component A and component B into the spraying machine with a mass ratio of 1:1 for spraying. The performance test results are shown in Table 2.

[0038] The product performance testing result that table 2 embodiment 2 obtains

[00...

Embodiment 3

[0042] Component A: Weigh 32 parts of polyether polyol (functionality: 3, molecular weight: 5000), 18 parts of liquefied starch, 5 parts of ammonium bicarbonate, 24 parts of water, 12.5 parts of tris(2-chloropropyl) phosphate , 2 parts of foam stabilizer (L6868, American Momentive), 1 part of epoxy adduct of fatty acid and 3 parts of catalyst dimethylcyclohexylamine, 1.5 parts of tris(dimethylaminopropyl) hexahydrotriazine, 3 parts of three 1 part of ethylenediamine is mixed evenly, and packaged for later use;

[0043] Component B: Weigh 50 parts of polymethylene polyphenyl polyisocyanate, 10 parts of diphenylmethane diisocyanate, 20 parts of isocyanate prepolymer, 15 parts of tris(2-chloroethyl) phosphate, tri(phosphate) 5 parts of butoxyethyl) ester are stirred evenly, and packaged for subsequent use;

[0044] Mixing and curing: Add component A and component B into the spraying machine with a mass ratio of 1:1 for spraying. The performance test results are shown in Table 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com