Method for prolonging service life of oxygen lance nozzle by reducing slag adhering to oxygen lance nozzle

An oxygen lance nozzle and life-span technology is applied in the field of prolonging the life of the oxygen lance nozzle by reducing the sticky slag of the oxygen lance nozzle. The amount of sticky slag and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

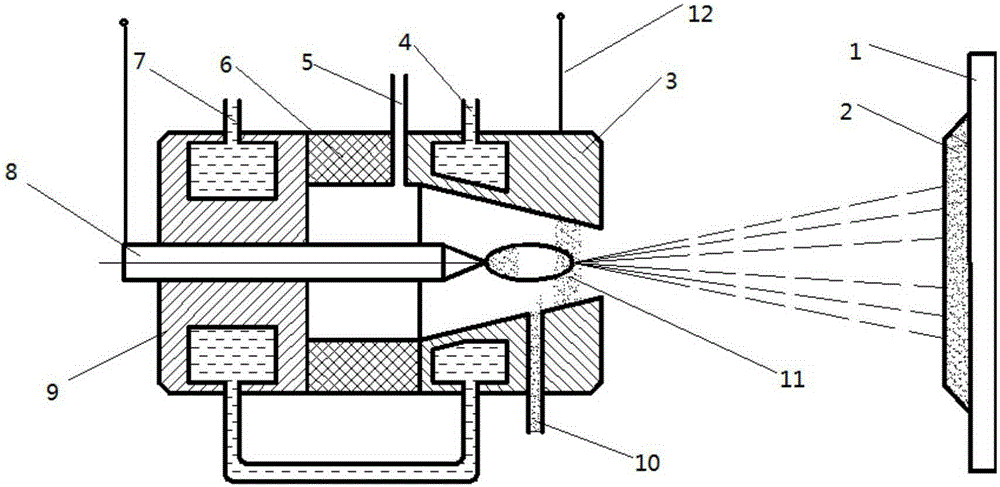

[0013] like figure 1 Shown, a kind of method that prolongs the life of oxygen lance nozzle by reducing sticky slag of oxygen lance nozzle, the steps of this method are as follows:

[0014] Step 1: Remove all dirt on the surface of the copper oxygen lance nozzle by steam degreasing and purging. After cleaning, bake the copper nozzle to obtain a clean oxygen lance nozzle;

[0015] Step 2: Fix the pre-sprayed oxygen lance nozzle on the oxygen lance nozzle fixing frame 1, and heat and preheat to 723K;

[0016] Step 3: Select a plasma spray gun with a maximum power of 80kW, a maximum current of 1000A, and a no-load voltage of 80V. In the plasma spray gun, argon gas is introduced, and the flow rate of argon gas is 8.4L min -1 11 between the cathode and anode nozzles uses argon gas as the gas medium to continuously and strongly ionize and generate a DC arc, and then introduces a flow rate of 11.6L min into the plasma gas inlet 5 -1 The argon gas is heated by the DC arc and ionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com