Novel antistatic and sterilization fiber treatment material and preparation method thereof

A fiber treatment and anti-static technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of low conductivity and charge storage, etc., and achieve the effect of simple preparation method, good antibacterial and bactericidal properties, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 50kg of polyethylene glycol with an average molecular weight of 800, 5kg of epoxy octyl soybean oil, 3kg of hydroxymethyl cellulose, 2kg of dihydroeoserveol, 1kg of polyethylene wax, 1kg of dicalcium phosphate dihydrate, poly Methylcyclotetrasiloxane 1kg, 4-guanidino-1-butanol 0.5kg and bergamot lactone 0.02kg, stir evenly with 200 rpm;

[0032] (2) Add 0.5kg of quinic acid and 0.5kg of polydimethylsiloxane diquaternary ammonium salt in turn, mix well at 80°C, adjust the pH value to 6.3 after cooling, and defoam in a vacuum defoamer for 8 minutes , to obtain antistatic, antibacterial fiber treatment materials.

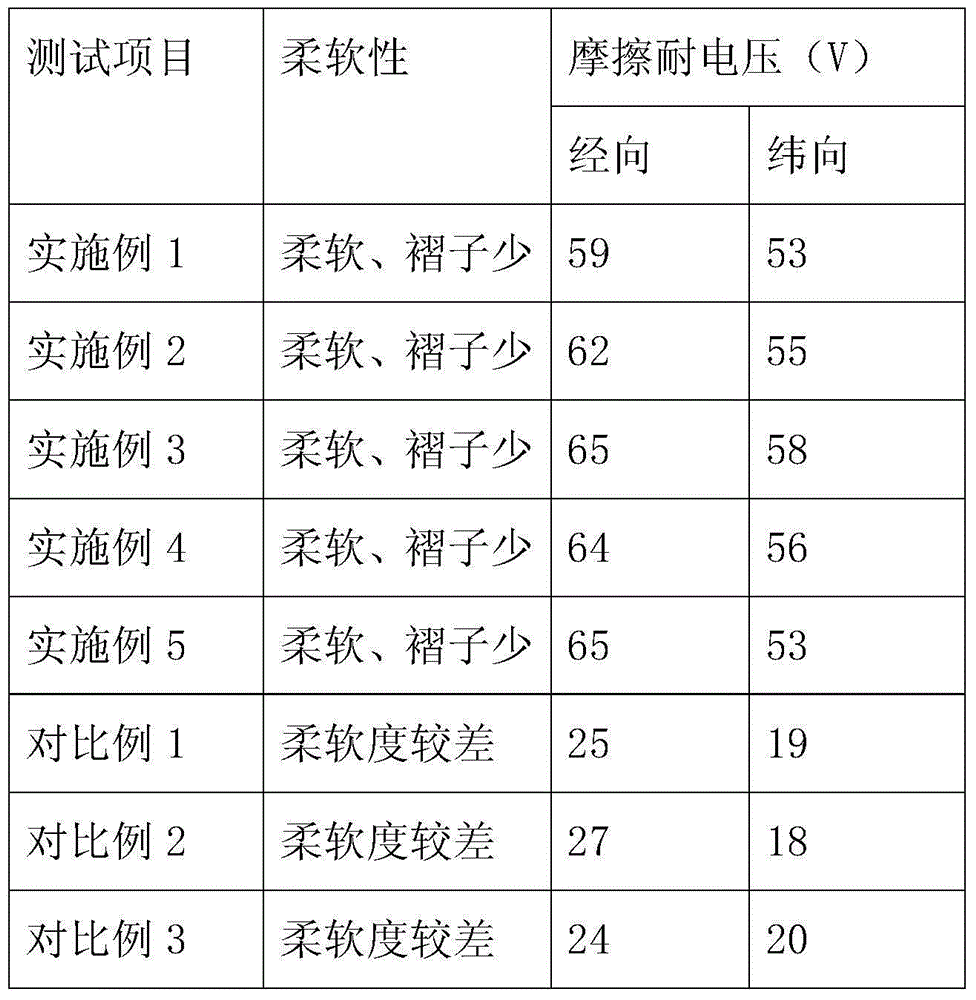

[0033] The performance test results of the prepared antistatic and sterilizing fiber treatment materials are shown in Table 1.

Embodiment 2

[0035] (1) Weigh 50kg of polyethylene glycol with an average molecular weight of 800, 5kg of epoxy octyl soybean oil, 3kg of hydroxymethyl cellulose, 2kg of dihydroeoserveol, 1kg of polyethylene wax, 1kg of dicalcium phosphate dihydrate, poly Methylcyclotetrasiloxane 1kg, 4-guanidino-1-butanol 0.5kg, bergamot lactone 0.02kg and zinc borate 0.3kg, stir evenly with 200 rpm;

[0036] (2) Add 0.5kg of quinic acid and 0.5kg of polydimethylsiloxane diquaternary ammonium salt in turn, mix well at 80°C, adjust the pH value to 6.3 after cooling, and defoam in a vacuum defoamer for 8 minutes , to obtain antistatic, antibacterial fiber treatment materials.

[0037] The performance test results of the prepared antistatic and sterilizing fiber treatment materials are shown in Table 1.

Embodiment 3

[0039] (1) Weighing 60kg of polyethylene glycol with an average molecular weight of 1000, 8kg of epoxy octyl soybean oleate, 5kg of hydroxymethyl cellulose, 4kg of dihydroeoserveol, 3kg of polyethylene wax, 3kg of dicalcium phosphate dihydrate, poly Methylcyclotetrasiloxane 2kg, 4-guanidino-1-butanol 1kg, bergamot lactone 0.08kg and zinc borate 0.3kg, stir evenly with 400 rpm;

[0040] (2) Add 2 kg of quinic acid and 1 kg of polydimethylsiloxane diquaternary ammonium salt in turn, mix uniformly at 100 ° C, adjust the pH value to 6.5 after cooling, and defoam in a vacuum defoamer for 10 minutes to obtain Anti-static, anti-bacterial fiber treatment material.

[0041] The performance test results of the prepared antistatic and sterilizing fiber treatment materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com