Aluminum alloy formwork embedded cross section profile and unit formwork structure thereof

A technology of aluminum alloy formwork and aluminum alloy, which is applied in the direction of formwork/formwork components, building structures, and on-site preparation of building components, which can solve the problems of unguaranteed safety performance, unreasonable cross-sectional structure, and difficulty in forming, etc. Problems, to achieve the effect of simple molding, quick and easy disassembly and assembly, and provide space for ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

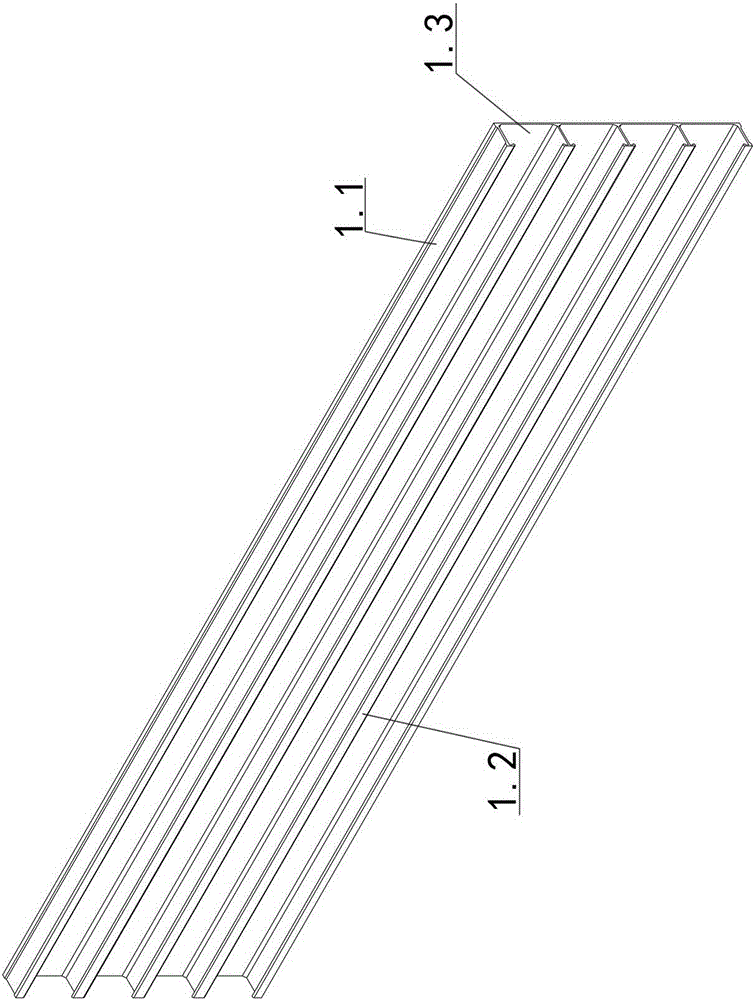

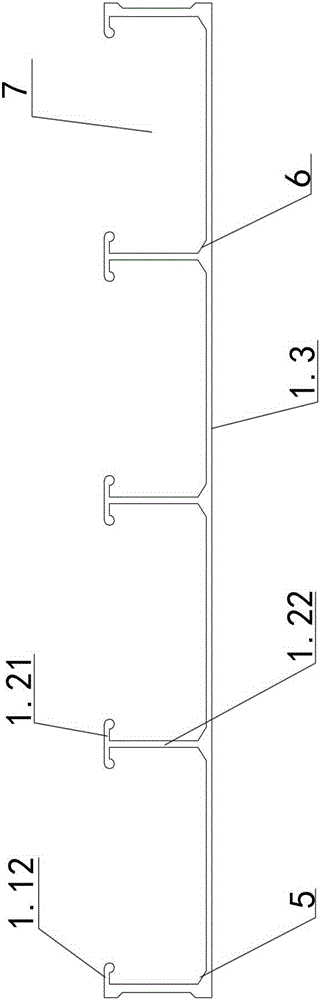

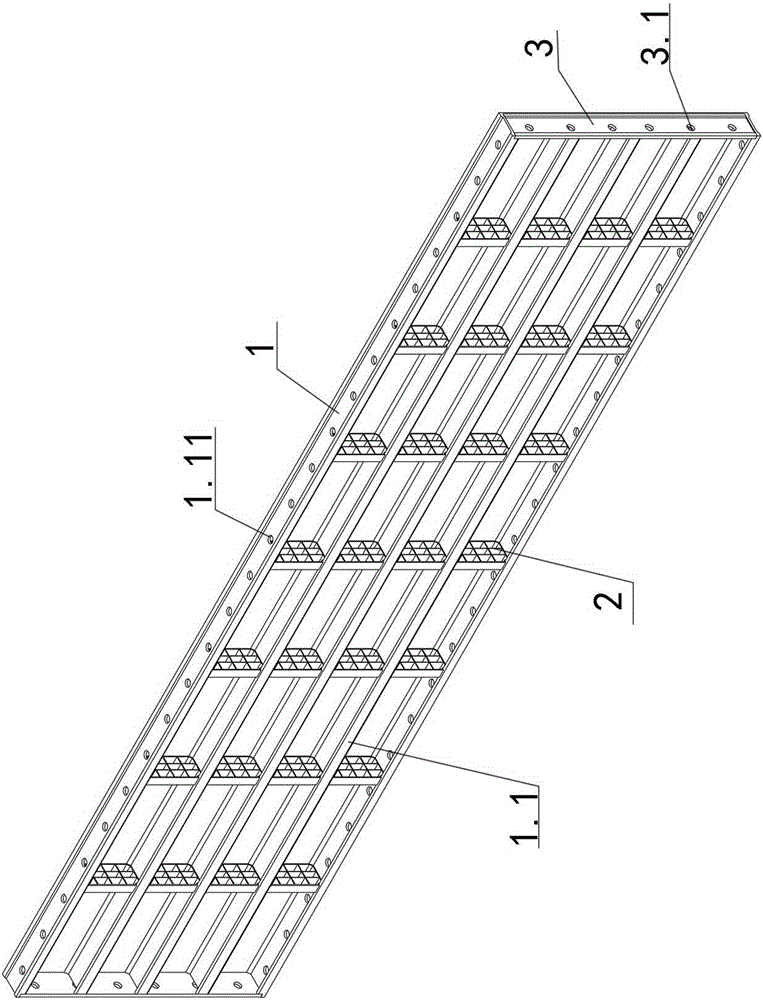

[0030] Examples see Figure 1-2 As shown, an aluminum alloy template embedded cross-section profile is an aluminum alloy special-shaped plate 1 extruded as a whole. The aluminum alloy special-shaped plate 1 is composed of a rectangular panel 1.3 and two opposite longitudinal side frames 1.1 on the back of the panel. formed by the tank body and the longitudinal reinforcing ribs 1.2 provided at the bottom of the tank body,

[0031] The bottom end of the longitudinal side frame 1.1 is connected to the panel through a chamfer a5, and the top end of the longitudinal side frame 1.1 extends horizontally toward the tank body to extend a section of first limiting arm 1.12,

[0032] The longitudinal reinforcing rib 1.2 is arranged at the center of the groove bottom or more than two are arranged to divide the space of the groove body equally. The frame 1.1 is equal in height and length, the cross-section of the longitudinal rib 1.2 is T-shaped, and the T-shaped flange forms two sections...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com