Enhanced heat exchange type heat pump system

A technology of heat pump system and enhanced heat exchange, which is applied in the direction of heat pump, fluid heater, refrigeration and liquefaction, etc. It can solve the problems of increasing equipment accident rate, increasing control difficulty, high manufacturing cost, etc., and achieves energy saving and applicability improvement and reduction Difficulty of installation, low maintenance rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

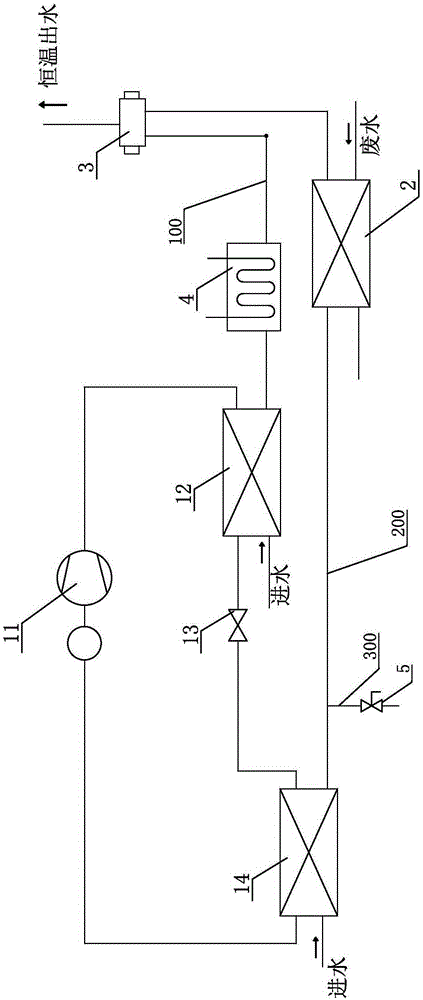

[0021] refer to figure 1 , the enhanced heat exchange heat pump system of the present invention includes a heat pump device, a waste heat exchanger 2, a first water inlet pipe 100 and a second water inlet pipe 200, and the heat pump device includes a compressor 11, a condenser 12, and a throttling device 13 , the evaporator 14 and the liquid accumulator, the compressor 11, the condenser 12, the throttling device 13, the evaporator 14 and the liquid accumulator form a closed loop through the refrigerant pipeline, and the first water inlet pipe 100 is connected to the water source and connected to all The condenser 12, the second water inlet pipe 200 is connected to a water source and communicated with the evaporator 14 and the waste heat exchanger 2. Here, the waste heat exchanger 2 can be either a heat exchanger for absorbing waste water heat energy or a heat exchanger for absorbing waste gas heat energy.

[0022] When the present invention works, the refrigerant circulates i...

Embodiment 2

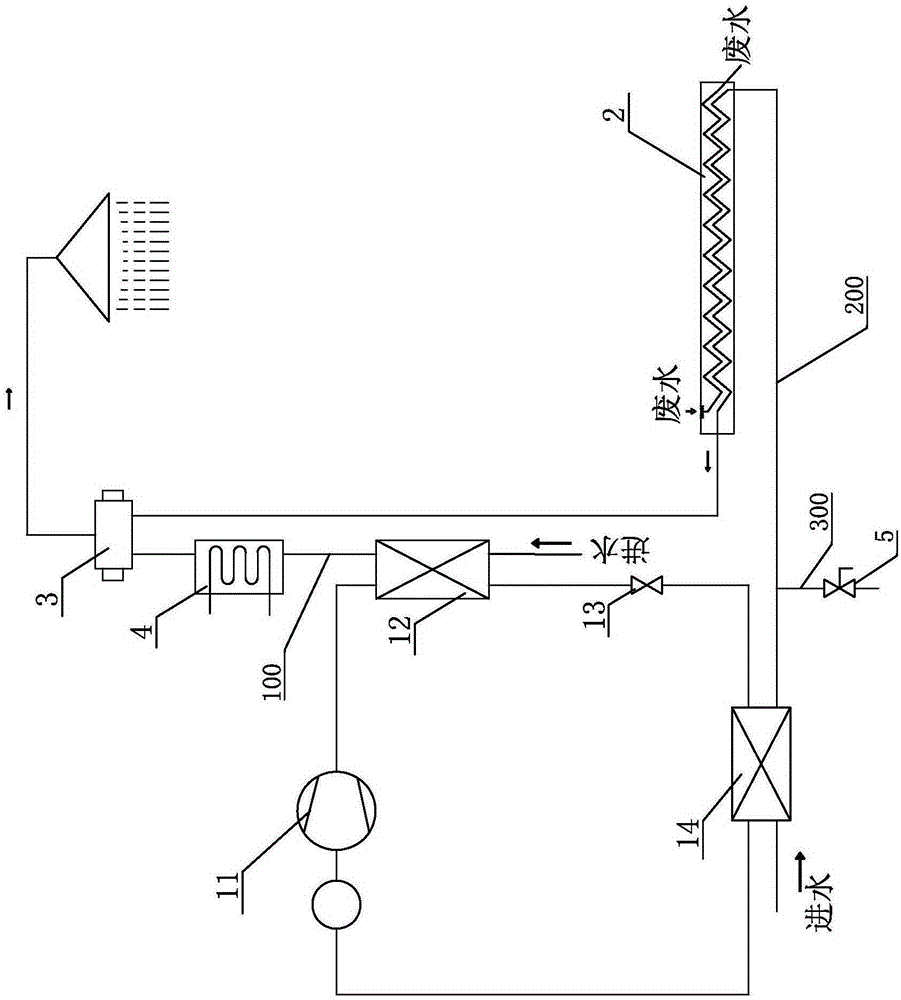

[0027] refer to figure 2 , which is different from Embodiment 1 in that the output end of the mixing valve 3 is connected with a shower for recovery of hot water and waste heat in the bathroom.

Embodiment 3

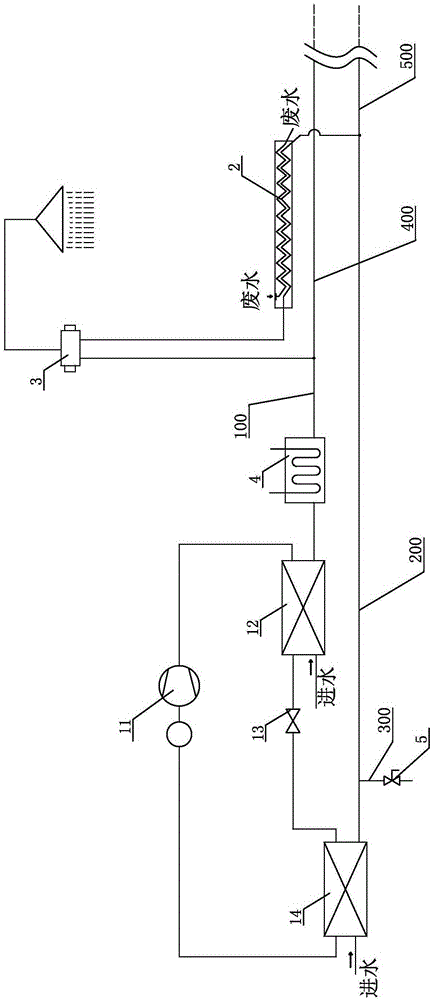

[0029] refer to image 3 , which is different from Embodiment 2 in that the first water inlet pipe 100 is connected with a hot water output branch 400 behind the condenser 12 to facilitate the output of the hot water flow formed after the heat exchange between tap water and the condenser 12 use.

[0030] The second water inlet pipe 200 is connected with a cold water output branch 500 between the evaporator 14 and the waste heat exchanger 2 , so as to facilitate the output of the cold water flow formed after the heat exchange between the tap water and the evaporator 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com