A low-melting-point nano-molten salt heat transfer heat storage medium and its preparation method

A technology of heat storage medium and low melting point, which is applied in the field of physical heat transfer and energy storage in high and new technology, can solve the problems of high melting point, low thermal conductivity and high melting point of molten salt, achieve cost reduction, good heat transfer and heat storage capacity, The effect of specific heat improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

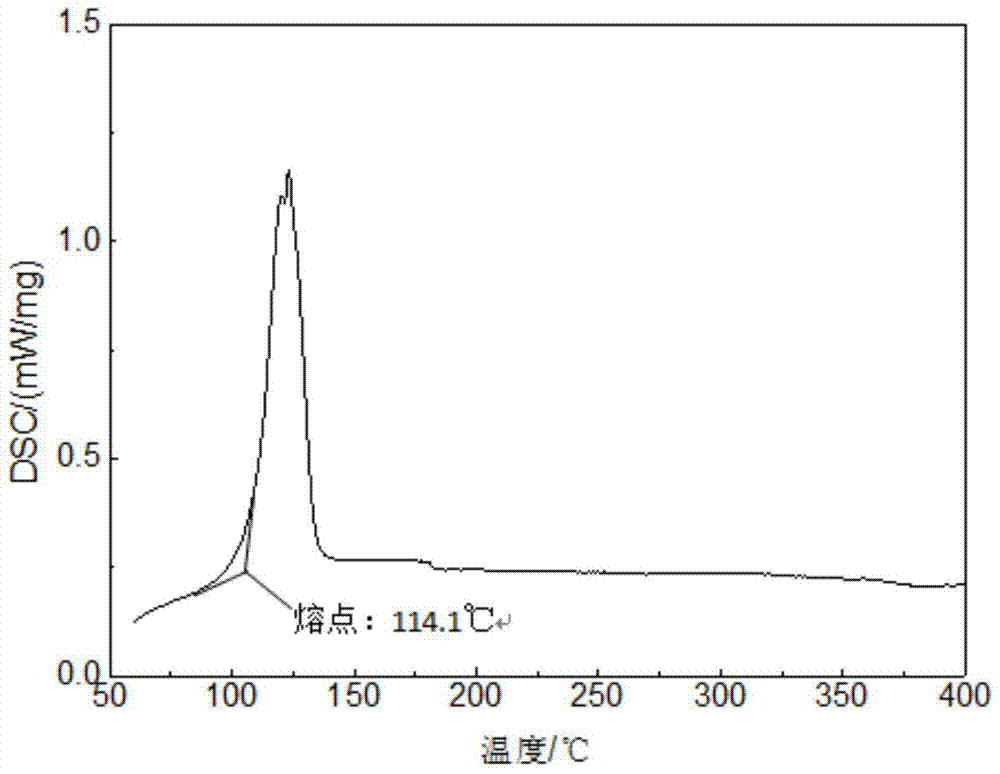

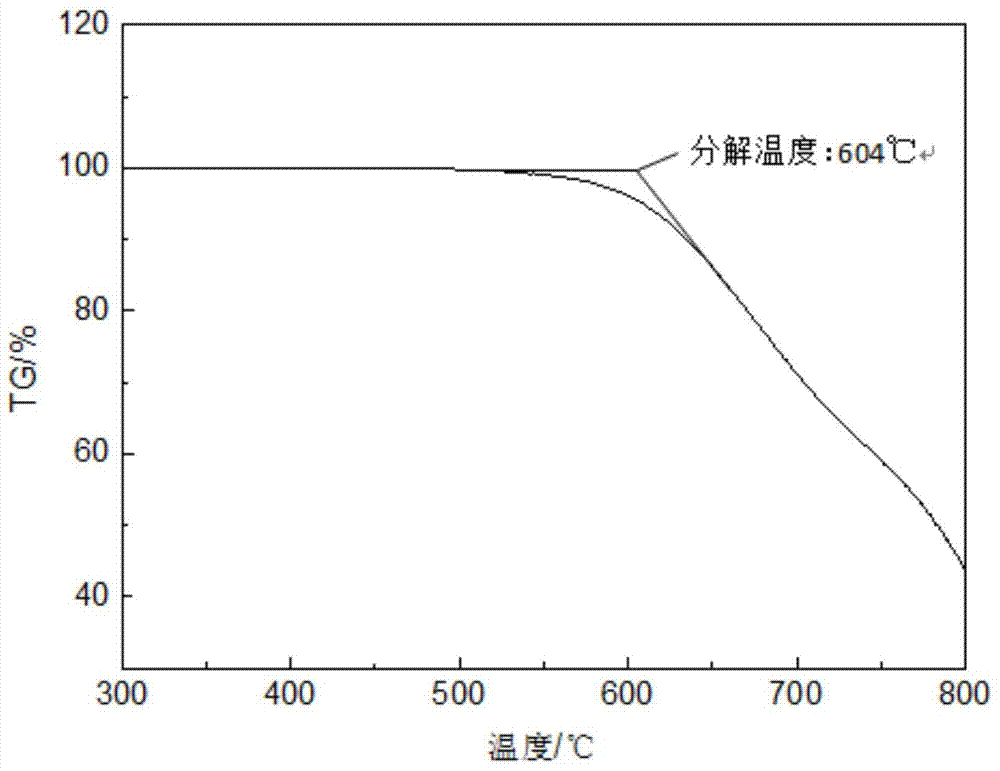

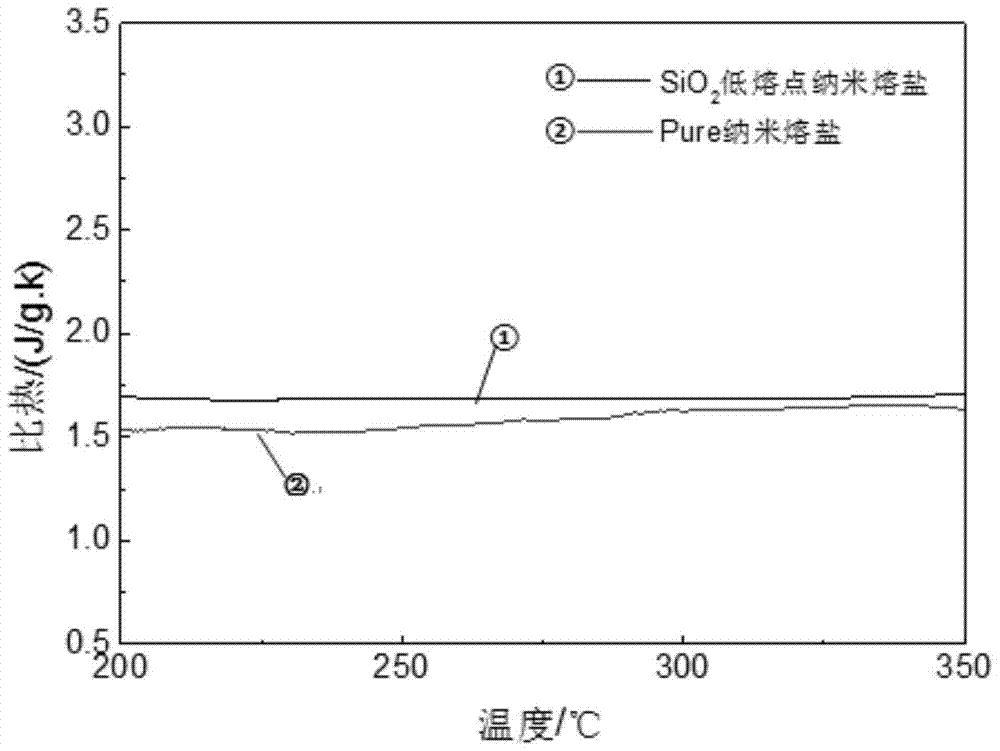

[0041] The low melting point nano molten salt is composed of 99wt% low melting point salt and 1wt% SiO 2 Nanoparticles, wherein the low melting point salt consists of 55wt% potassium nitrate, 9wt% sodium nitrate, 18wt% lithium nitrate and 18wt% calcium nitrate, SiO 2 The particle size of the nanoparticles is 20 nm. The melting point of the low melting point nano molten salt was analyzed by DSC (differential scanning calorimetry), its decomposition temperature was analyzed by TG (thermogravimetry), and its specific heat was analyzed by DIN51007 standard method. The results show that its melting point is 114.1 ℃, the decomposition temperature is 604 ℃, and the specific heat of the formula low melting point nano molten salt in liquid state is about 1.8-2.0J / g.k. figure 1 is the DSC curve of this sample. figure 2 is the TG curve of this sample. image 3 is the specific heat test result of the sample.

[0042]Compared with the pure low melting point mixed molten salt, the low ...

Embodiment 2

[0045] The low melting point nano molten salt is composed of 99wt% low melting point salt and 1wt% Al 2 O 3 Nanoparticles, wherein the low melting point salt consists of 55wt% potassium nitrate, 9wt% sodium nitrate, 18wt% lithium nitrate and 18wt% calcium nitrate, Al 2 O 3 The particle size of the nanoparticles is 20 nm. The results show that its melting point is 108.8 °C, its decomposition temperature is 595 °C, and the specific heat of the formula low melting point nano molten salt in liquid state is about 2.4-2.6J / g.k. Figure 4 is the DSC curve of this sample. Figure 5 is the TG curve of this sample. Image 6 is the specific heat test result of the sample.

[0046] Compared with the pure low melting point mixed molten salt, the low melting point nano molten salt of the formula has a melting point increased by about 20°C, the decomposition temperature does not change greatly, and has a wider temperature range compared with the pure low melting point mixed molten salt....

Embodiment 3

[0049] The low melting point nano molten salt is composed of 99wt% low melting point salt and 1wt% TiO 2 Nanoparticles, wherein the low melting point salt consists of 55wt% potassium nitrate, 9wt% sodium nitrate, 18wt% lithium nitrate and 18wt% calcium nitrate, TiO 2 The particle size of the nanoparticles is 20 nm. The results show that its melting point is 112.2℃, its decomposition temperature is 579℃, and its specific heat is about 1.6-1.9J / g.k when the low-melting point nano molten salt is liquid. Figure 7 is the DSC curve of this sample. Figure 8 is the TG curve of this sample. Figure 9 is the specific heat test result of the sample.

[0050] Compared with the pure low melting point mixed molten salt, the low melting point nano molten salt of the formula has a melting point increased by about 20°C, and the decomposition temperature is slightly reduced, but it still has a wide range of use temperature.

[0051] At 300°C, the specific heat of the low melting point nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com