Laser beam quality factor measurement method

A technology of laser beam quality and measurement method, applied in the direction of testing optical performance, etc., to achieve the effect of easy popularization, accurate measurement accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

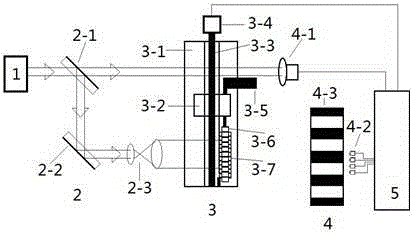

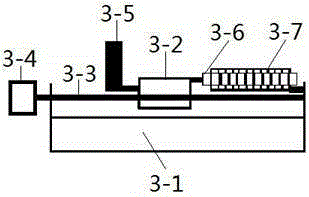

[0031] Such as figure 1As shown, a laser beam quality M^2 factor measurement method is characterized in that: at least one laser 1 to be measured is included, and the laser 1 divides the output light of the laser 1 into two beams through the optical unit 2, and the output light from the optical unit 2 The first beam of parallel beams is irradiated on the power detector 4-1; the second beam of parallel beams split by the optical unit 2 is irradiated on the input surface of the Moiré fringe generator composed of the scale grating 3-6 and the indicator grating 3-7. There is a photoelectric detection unit at the output end of the fringe generator, and the indicating grating 3-7 is fixed on the mechanical scanner; a knife edge 3-5 is installed on the mechanical scanner 3; the mechanical scanner drives the indicating grating 3-7 under the control of the control unit Move synchronously with the knife edge 3-5; make the edge of the knife edge 3-5 partially block the receiving light wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com