Rock soil seepage monitoring sensor and manufacturing method

A technology for monitoring sensors and seepage, which is used in fluid velocity measurement, fluid resistance measurement, instruments, etc. It can solve the problems of continuous monitoring of difficult-to-integrate sensors and high cost, and achieve the effects of simple structure, small measurement distance and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

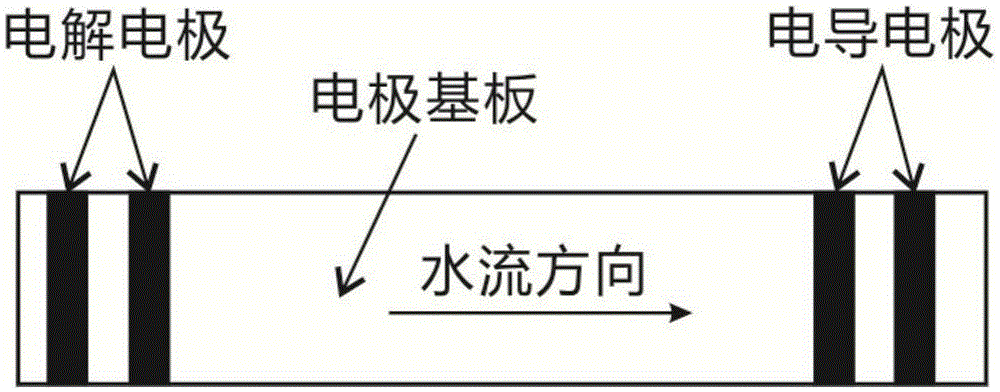

[0027] Example 1: Measure the conductivity at 50-1500μScm -1 Natural water between, flow rate range 0.01cms -1 -0.1cms -1 , a flow velocity measurement sensor with a fixed direction and a preparation method thereof,

[0028] Such as figure 1 As shown, the sensor includes a substrate and a pair of electrolytic electrodes and one or more pairs of conduction electrodes fixedly arranged on the substrate;

[0029] The electrolytic electrodes are used to generate electrolytic polarization;

[0030] The conductivity electrode is used to measure the conductivity of the system;

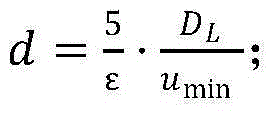

[0031] Take the minimum flow rate u min =0.01cm·s -1 ,D L =10 -5 cm 2 ·s -1 , ε=1%, calculate the minimum distance d between the electrolytic electrode and the conductance electrode, d = 5 ϵ · D L u min = 0.5 c ...

example 2

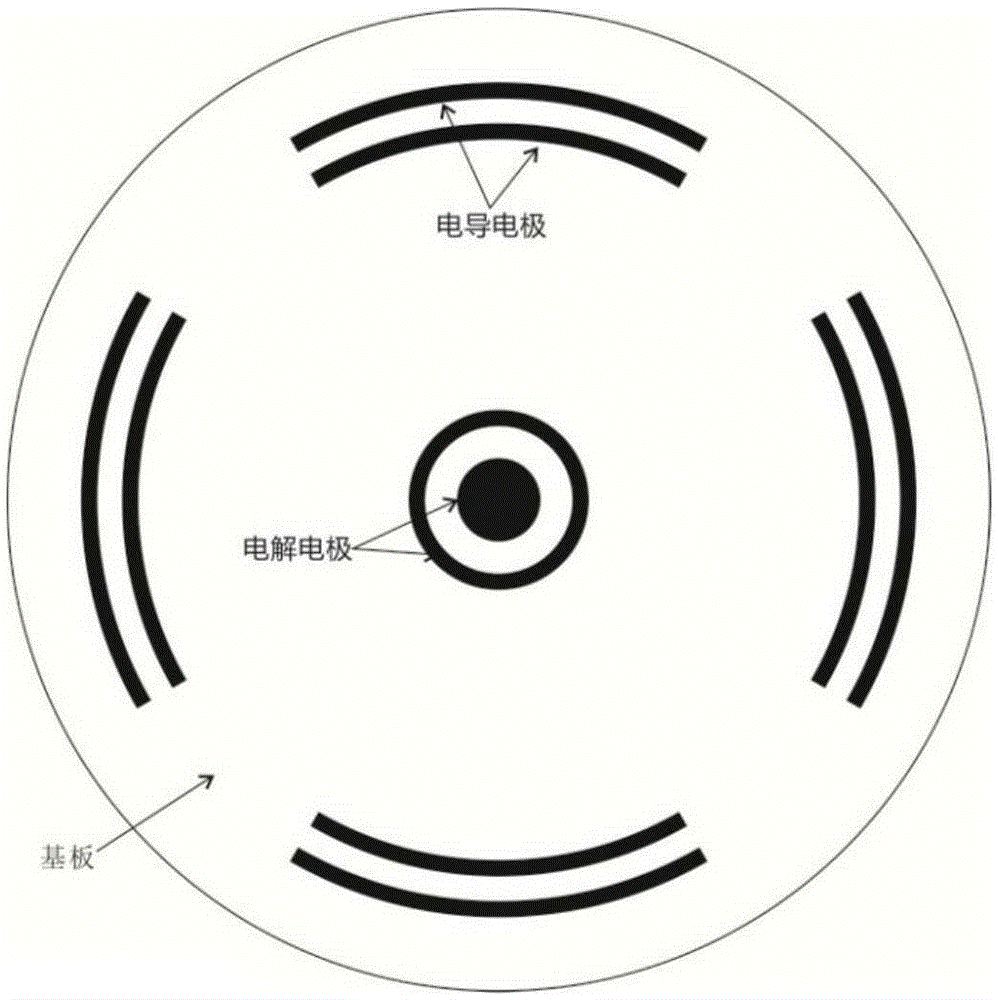

[0041] Example 2: Measure the conductivity at 50-1500μScm -1 Natural water between, flow rate range 0.01cms -1 -0.1cms -1 , Flow rate measurement sensor with non-fixed direction and preparation method.

[0042] Such as figure 2 As shown, the sensor includes a substrate and a pair of electrolytic electrodes and one or more pairs of conduction electrodes fixedly arranged on the substrate;

[0043] The electrolytic electrodes are used to generate electrolytic polarization;

[0044] The conductivity electrode is used to measure the conductivity of the system;

[0045] Take the minimum flow rate u min =0.01cm·s -1 ,D L =10 -5 cm 2·s -1 , ε=1%, calculate the minimum distance d between the electrolytic electrode and the conductance electrode, d = 5 ϵ · D L u min = 0.5 c m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com