Seaweed flavor enhancer and making method thereof

A technology of umami and seaweed, applied in food preparation, food ingredients as taste improvers, functions of food ingredients, etc., to achieve the effects of high nutritional value, simple manufacturing process, and rich raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

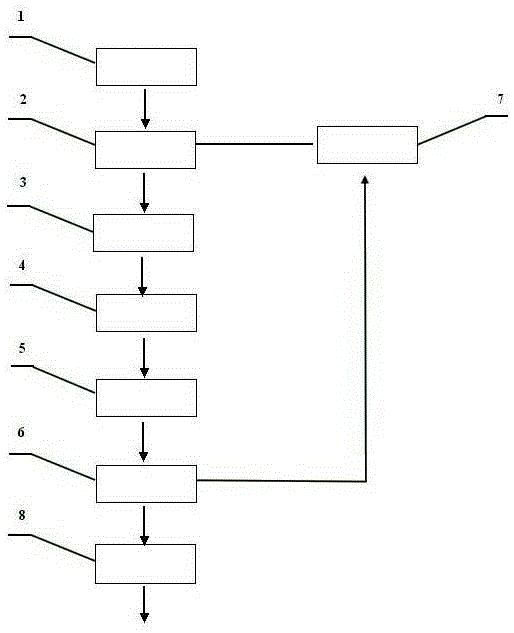

Image

Examples

Embodiment 1

[0020] Embodiment 1: 20 parts by weight of edible salt, 6 parts of soft white sugar, and 35 parts of monosodium glutamate are crushed into 80 meshes one by one with a pulverizer-1; then 5 parts of glucose, 5 parts of lactose, 10 parts of cornstarch, and 5 parts of maltodextrin 1 part, 2 parts of I+G, 1 part of yeast extract, 1 part of bonito powder, 1 part of mushroom powder, 1 part of chlorella powder and 8 parts of water, all the above raw materials are put into the mixer 2 and stirred for 15 minutes; The material is loaded into the granulator 3 for granulation, and the mesh number of the sieve of the granulator 3 is 14-16 mesh, that is, the particle size of the material is 14-16 mesh; The sensory, physical and chemical indicators and microbial indicators meet the standard requirements, and the granulated materials are placed in the drying box 4 at 80-105±3°C for more than 2 hours, and then dried and sterilized; after drying and sterilized, they are placed in the drying room ...

Embodiment 2

[0021] Embodiment two: by weight 25 parts of edible salt, 5 parts of soft white sugar, 30 parts of monosodium glutamate, one by one with pulverizer-1 pulverized into 80 orders; then 5 parts of glucose, 6 parts of lactose, 6 parts of cornstarch, maltodextrin 6 parts, 3 parts of I+G, 2 parts of yeast extract, 1 part of bonito powder, 1 part of mushroom powder, 2 parts of green algae powder, 6 parts of water, all the above raw materials are put into the mixer 2 and stirred for 15 minutes; the following are exactly the same as the examples one.

Embodiment 3

[0022] Embodiment three: 30 parts by weight of edible salt, 5 parts of soft white sugar, and 29 parts of monosodium glutamate are pulverized into 80 meshes with pulverizer one by one; then 5 parts of glucose, 5 parts of lactose, 7 parts of cornstarch, maltodextrin 4 parts, 3 parts of I+G, 1 part of yeast extract, 2 parts of bonito powder, 1 part of mushroom powder, 2 parts of green algae powder, 6 parts of water, all the above raw materials are put into the mixer 2 and stirred for 15 minutes; the following are exactly the same as the examples one.

[0023] In the above-mentioned embodiment, the green algae powder is replaced by kombu powder, which has the same weight, which is a kind of kombu protein flavoring, which has the same effect as seaweed umami flavoring.

[0024] Said edible salt: refers to the processed edible salt obtained from seawater, underground rock (mine) salt deposits, natural brine (salt) water with sodium chloride as the main component, excluding low-sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com