A method for preparing compound deodorant by using beverage processing waste residue

A deodorant and waste residue technology, which is applied in the field of compound deodorant preparation, can solve the problem that the residue is not fully utilized, and achieve good effect, cheap and easy-to-obtain raw materials, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

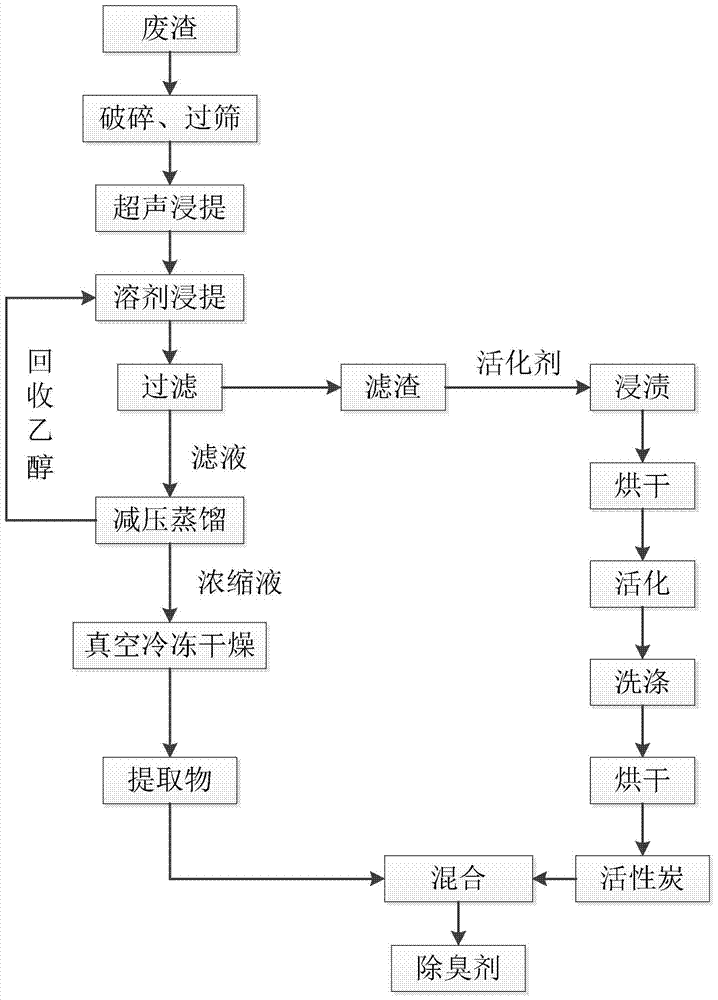

[0027] please see figure 1 .

[0028] A. Take tea dregs from a tea beverage processing factory in Fujian, coffee bean residue from a coffee processing factory in Yunnan, and grape seeds from a wine processing factory in Anhui according to a mass ratio of 1:1:1, mix them, crush them, pass through a 50-mesh sieve, and Add 40% mass percent ethanol aqueous solution to the undersize, shake well, and vibrate at a frequency of 150W in an ultrasonic water bath for 15 minutes; reflux leaching twice in a 60°C constant temperature water bath, during the leaching process, use 125r / min Stir at high speed, filter the two extracts respectively, combine the filtrates, and dry the filter residue for use;

[0029] B. Distill the filtrate combined in the previous step at 45°C under reduced pressure to obtain the extract concentrate and ethanol aqueous solution. The time of vacuum distillation is based on the fact that ethanol cannot be detected in the ethanol aqueous solution, and then detect t...

Embodiment 2

[0034] A. Mix tea dregs from a tea beverage processing factory in Fujian, coffee bean residue from a coffee processing factory in Yunnan, and grape seeds from a wine processing factory in Anhui at a ratio of 1:2:1. After the waste residues are crushed and passed through a 100-mesh sieve, add 60% ethanol aqueous solution, Shake well, shake in an ultrasonic water bath at a frequency of 200W for 20 minutes; then reflux and extract twice in a constant temperature water bath at 65°C, stir at a rate of 150r / min during the extraction process, filter the two extracts separately, and combine the filtrates , the filter residue is dried for later use;

[0035] B. Distill the combined filtrate of step A at 50°C under reduced pressure and recover the aqueous ethanol solution until no ethanol is detected in the aqueous ethanol solution to obtain the concentrated extract; freeze the concentrated extract and freeze-dry it in a vacuum to obtain the crude polyphenol extract powder;

[0036] C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com