VOC (volatile organic compound) waste gas treatment device and method for pharmaceutical and chemical industry

A waste gas treatment device and waste gas treatment technology are applied in the direction of chemical instruments and methods, combustion methods, combined devices, etc., to achieve the effects of scientific design, good practical application value and promotion value, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

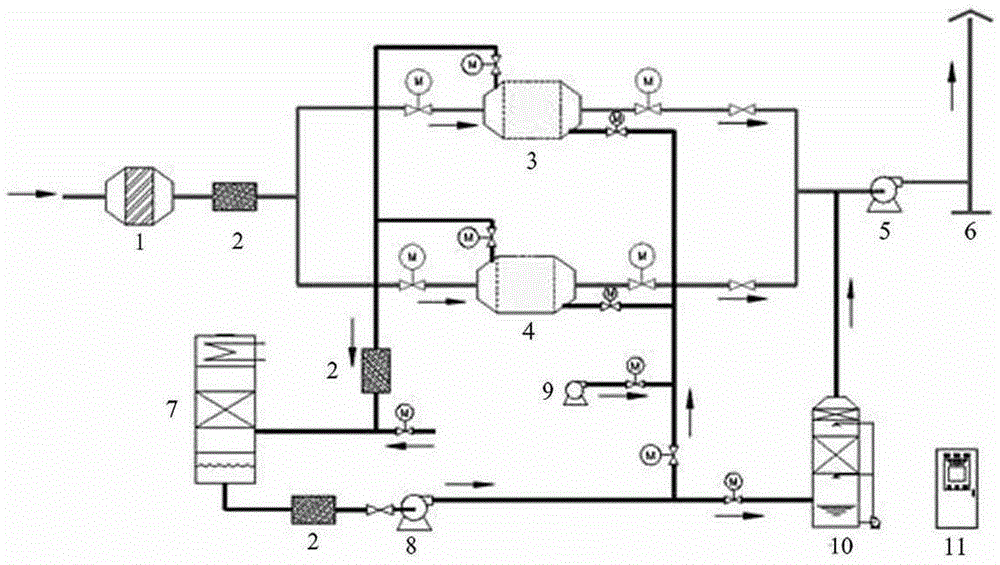

[0028] Such as figure 1 As shown, a VOC waste gas treatment device for the pharmaceutical and chemical industry, along the waste gas treatment process, sequentially includes an acid mist adsorption tower 1 connected to the air outlet of the VOC waste gas source fan, an activated carbon adsorption bed device connected to the acid mist adsorption tower 1, and Connect the main exhaust fan 5 of the activated carbon adsorption bed device, connect the chimney 6 of the main exhaust fan 5;

[0029] The activated carbon adsorption bed device is also connected to the catalytic combustion device 7, and the catalytic combustion device 7 is connected to the desorption fan 8 and the spray tower 10. One end of the desorption fan 8 is connected to the end of the cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com