Novel gas-blowing gun

An air blowing gun and a new type of technology are used in cleaning methods, spraying devices, liquid spraying devices and other directions using gas flow, which can solve the problems of cumbersome transportation of workpieces, time-consuming and laborious safety, etc., and achieve simple and reasonable equipment structure. The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

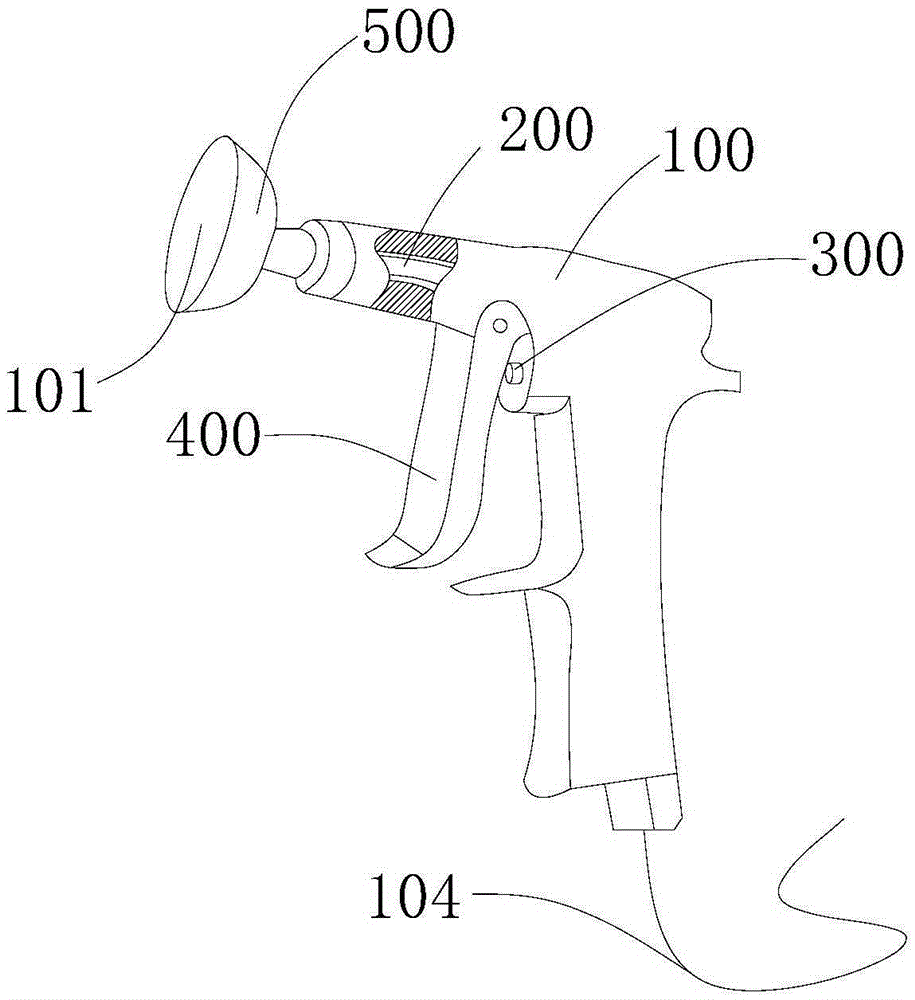

[0050] see Figure 1-3 , the embodiment of the present invention provides a new type of air blow gun, including a casing 100 and a switch assembly, wherein:

[0051] The casing 100 is provided with an air pipe 200, the air pipe 200 includes an air inlet and an air outlet, the air inlet is connected to the air compressor through the bellows 104, and the air outlet is located at the air outlet of the casing 100 The switch assembly includes a valve 300 and a handle 400 connected to the valve 300, the valve 300 is located in the casing 100, and the valve 300 communicates with the air pipe 200; the handle 400 is installed on the machine On the shell 100, the opening of the valve 300 is controlled by pressing the handle 400;

[0052] The novel air blow gun also includes a bowl-shaped windshield 500, the windshield 500 is positioned at the air outlet end of the casing 100, and the windshield 500 is detachably connected to the casing 100, and the windshield 500 The recessed portion ...

Embodiment 2

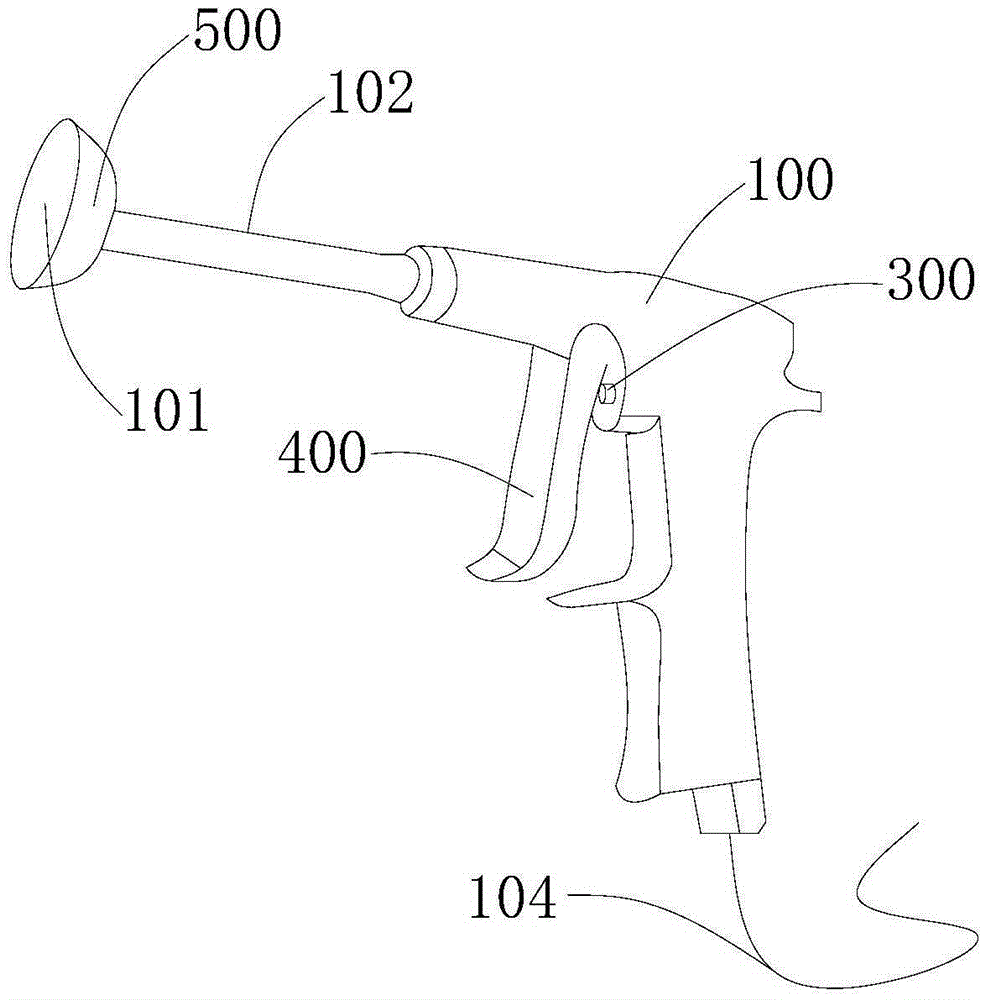

[0061] see Figure 4-6 , this embodiment also provides a new type of air blow gun, this embodiment is a further improvement on the basis of the technical solution in the first embodiment, the technical solution described in the first embodiment is also applicable to this embodiment, the description in the first embodiment The technical solution will not be described repeatedly, as follows:

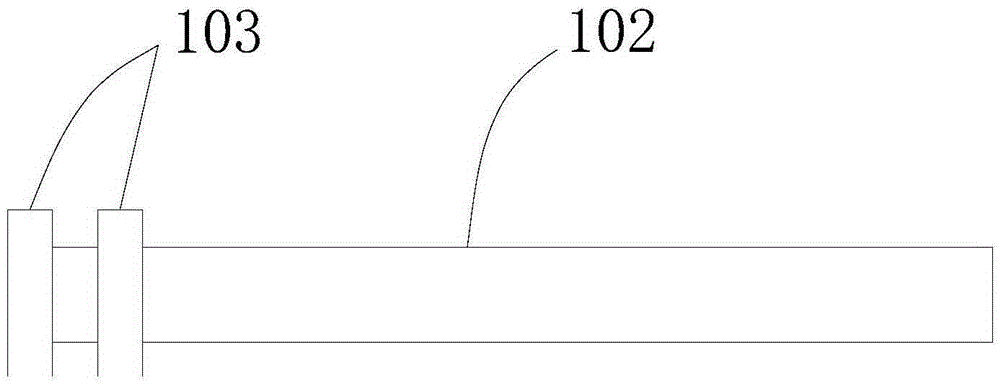

[0062] The first rod part 201 is inserted into the second rod part 202, and the first rod part 201 and the second rod part 202 are connected by threads; the first rod part 201 includes a threaded rod part 302 and a straight rod part 301 , the threaded rod part 302 is screwed to the second rod part 202 , and the outer diameter of the straight rod part 301 is the same as the outer diameter of the second rod part 202 . The length of steel pipe 102 is adjusted accordingly according to needs, and it is more convenient to use. In some areas with large depth, the length of steel pipe 102 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com