Nano-scale ordered mesoporous silicon dioxide spheres and preparation method of same

A technology of mesoporous silica and silica spheres, applied in the field of inorganic porous materials, can solve the problems of high toxicity and high cost, and achieve low cost, short production cycle and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A nanoscale ordered mesoporous silica sphere, the preparation method is as follows:

[0031] Fully dissolve 0.16g of ionic liquid in 81ml of ethanol / water (28ml of ethanol, 53ml of water), add 1ml of ammonia water, stir vigorously at 22°C for 30min, then add 1ml of tetraethyl orthosilicate under stirring, and continue at 22 The reaction was stirred at ℃ for 6 hours, the reaction mixture was filtered and washed, dried at 50℃ for 6 hours, calcined in air at 600℃ for 6 hours, and then cooled to room temperature to obtain nanoscale ordered mesoporous silica spheres.

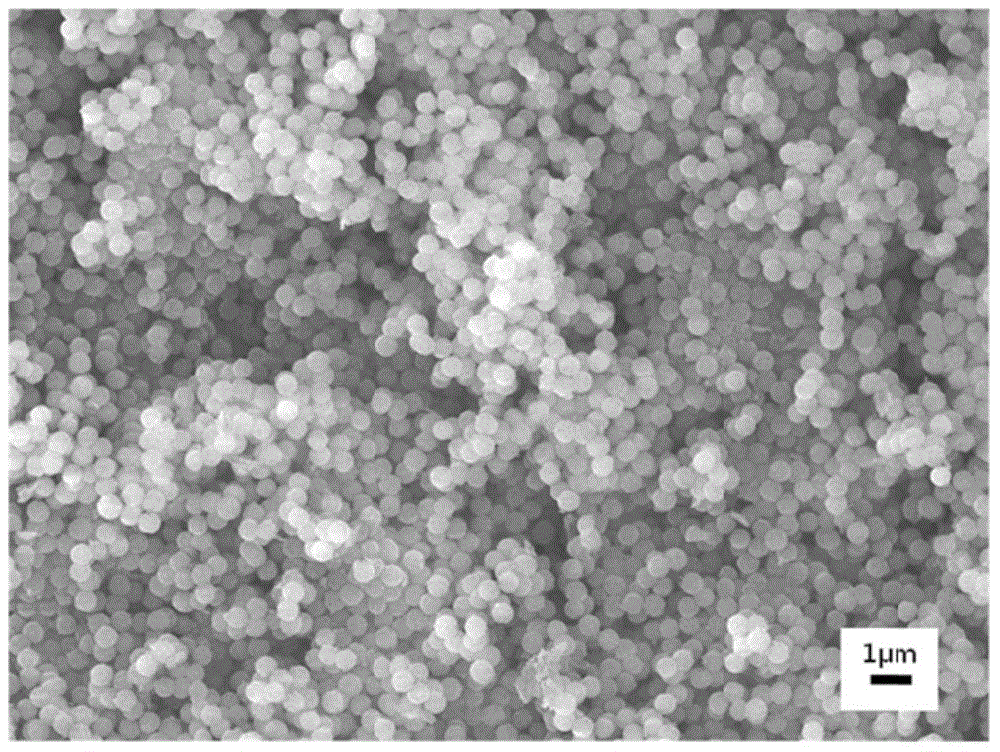

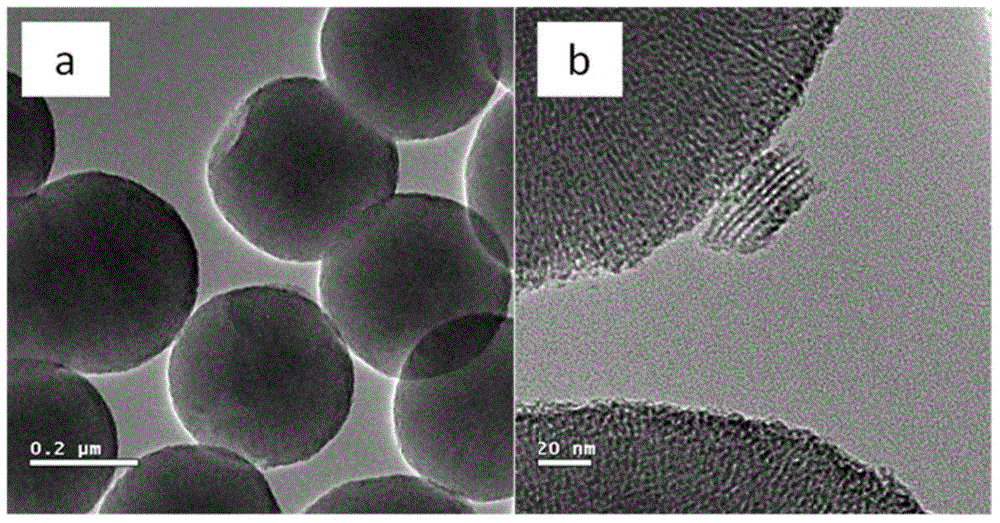

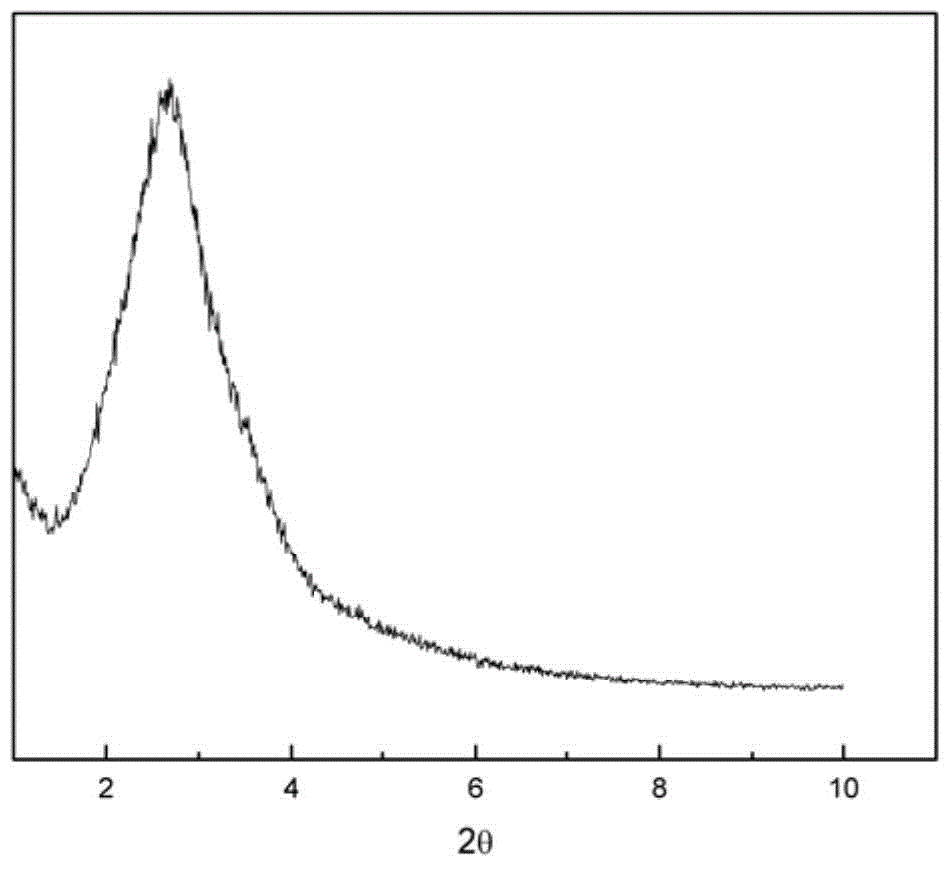

[0032] The nanoscale ordered mesoporous silica spheres have an average particle diameter of 320nm, a mesopore diameter of 3.81nm, and a specific surface area of 1156m 2 / g, the pore volume is 0.73cm 3 / g, uniform in size and shape, with an ordered mesoporous channel structure arranged radially from the center of the sphere to the outer surface.

Embodiment 2

[0034] A nanoscale ordered mesoporous silica sphere, the preparation method is as follows:

[0035] Dissolve 0.16g of ionic liquid in 81ml of ethanol / water (30.5ml of ethanol, 50.5ml of water), add 1ml of ammonia water, stir vigorously at 22°C for 30min, then add 1ml of tetraethyl orthosilicate under stirring, and continue to Stirring and reacting at 22°C for 6 hours, the reaction mixture was filtered and washed, dried at 50°C for 6 hours, and calcined at 600°C in an air environment for 6 hours to obtain nanoscale ordered mesoporous silica spheres.

[0036] The nanoscale ordered mesoporous silica spheres have an average particle diameter of 500nm, a mesopore diameter of 3.38nm, and a specific surface area of 1194m 2 / g, the pore volume is 0.81cm 3 / g, uniform in size and shape, with an ordered mesoporous channel structure arranged radially from the center of the sphere to the outer surface.

Embodiment 3

[0038] A nanoscale ordered mesoporous silica sphere, the preparation method is as follows:

[0039] Dissolve 0.16g of ionic liquid in 81ml of ethanol / water (22.0ml of ethanol, 59.0ml of water), add 1ml of ammonia water, stir vigorously at 22°C for 30min, then add 1ml of tetraethyl orthosilicate under stirring, continue to Stirring and reacting at 22°C for 6 hours, the reaction mixture was filtered and washed, dried at 50°C for 6 hours, and calcined at 600°C in an air environment for 6 hours to obtain nanoscale ordered mesoporous silica spheres.

[0040] The nanoscale ordered mesoporous silica spheres have an average particle diameter of 150nm, a mesopore diameter of 3.43nm, and a specific surface area of 1615m 2 / g, the pore volume is 1.16cm3 / g, uniform in size and shape, with an ordered mesoporous channel structure arranged radially from the center of the sphere to the outer surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com