Acidic drip irrigation fertilizer for processing tomatoes and preparation method

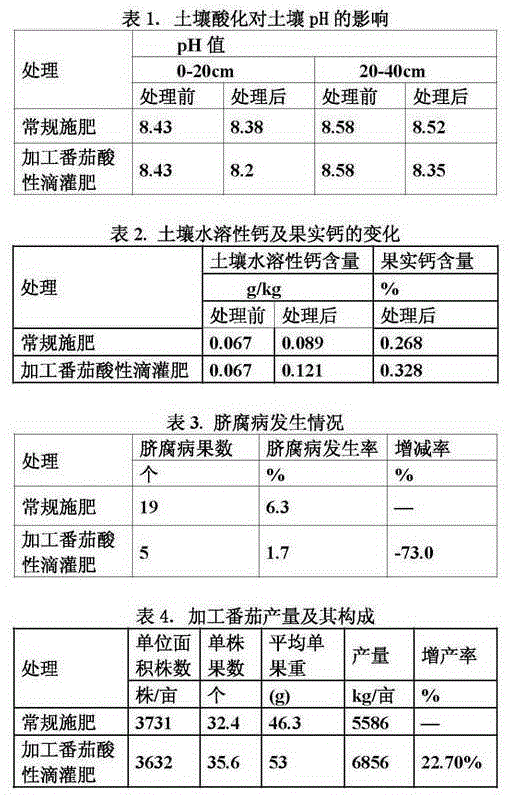

A technology for processing tomatoes and acidity, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of clogging drippers, increase the yield of processed tomatoes, etc., so as to prevent clogging of drippers, reduce the incidence of umbilical rot, and make fertilizers simple and easy. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The processed tomato acidic drip irrigation fertilizer mainly includes the following raw materials in parts by weight: 21 parts of ammonium sulfate; 33 parts of urea phosphate; 46 parts of potassium nitrate; wherein the effective nutrient composition contains N: 16.5%, P 2 o 5 : 15%, K 2 O: 20%, total nutrients (N-P 2 o 5 -K 2 O) content = 50.5% ≥ 50%, in line with the Ministry of Agriculture water-soluble fertilizer NY: 1107-2010 requirements.

[0040] The preparation method of the above-mentioned processing tomato acidic drip irrigation fertilizer: the raw materials of the above-mentioned ratio are pulverized and then sieved, and the mesh number of the sieve is 45 mesh; The acidic drip irrigation fertilizer can be obtained, and the mesh number of the secondary sieving is 70 mesh.

[0041] The processed tomato acidic drip irrigation fertilizer is easily soluble in water, and is applied when crops are drip-irrigated, so that the crops can effectively absorb the nut...

Embodiment 2

[0043] This processed tomato acidic drip irrigation fertilizer mainly includes the following raw materials in parts by weight: 18 parts of ammonium sulfate; 34 parts of urea phosphate; 48 parts of potassium nitrate, total nutrient (N-P 2 o 5 -K 2 O) Content (16.28%+15.30%+21.12%)=52.70%;

[0044] The raw materials in the above ratio are crushed and then sieved, and the mesh size of the sieve is 40 meshes; then the sieved raw materials are mixed and crushed for the second time, and then sieved for the second time, the mesh size of the second sieve is It is 80 mesh.

Embodiment 3

[0046] This processing tomato acidic drip irrigation fertilizer mainly includes the following raw materials in parts by weight: 21 parts of ammonium sulfate; 34 parts of urea phosphate; 45 parts of potassium nitrate, total nutrient (N-P 2 o 5 -K 2 O) content (16.50%+15.30%+19.80%)=51.60%;

[0047] The raw materials in the above ratio are crushed and then sieved, and the mesh size of the sieve is 50 mesh; then the sieved raw materials are mixed and crushed for the second time, and then sieved for the second time, the mesh size of the second sieve is It is 70 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com