Long-acting glass antifog membrane and preparation method thereof

An anti-fog film and glass technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of use effect, light transmittance, unstable glass surface, etc., and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

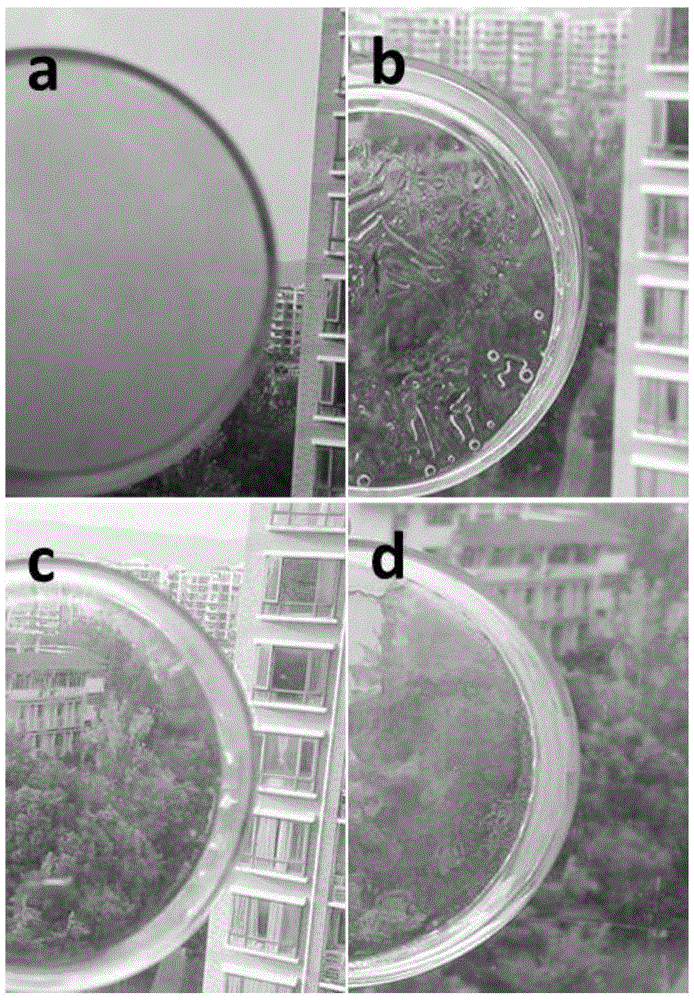

Image

Examples

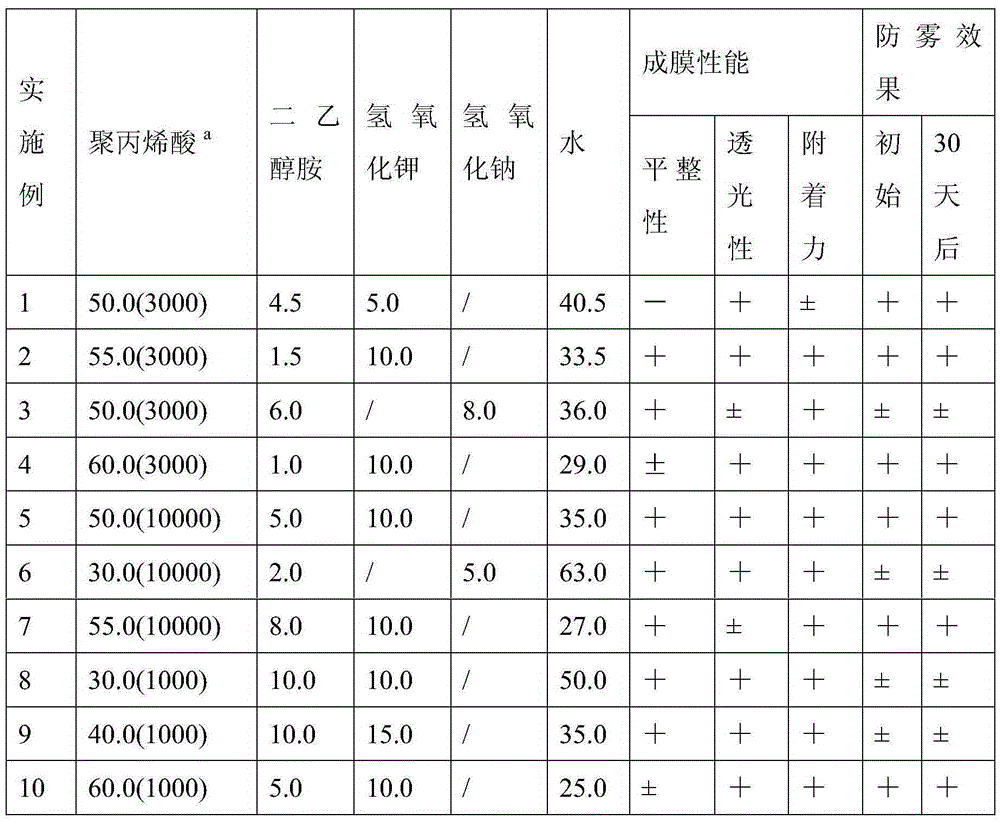

Embodiment 1

[0016] In a 200mL beaker, weigh 50g of polyacrylic acid with a molecular weight of 3000, 4.5g of diethanolamine, and 5.0g of potassium hydroxide, and add them to 40.5g of deionized water in order, and obtain an antifogging agent after completely dissolving, and then pipette 5mL of antifogging agent. Put the spray agent in a clean petri dish, scrape it carefully with a glass rod, place it in an oven at 80°C, and dry it while reacting, take it out after 2 hours, and make a long-lasting glass anti-fog film.

Embodiment 2

[0018] In a 200mL beaker, weigh 55g of polyacrylic acid with a molecular weight of 3000, 1.5g of diethanolamine, and 10.0g of potassium hydroxide, and add them to 33.5g of deionized water in order, and obtain an antifogging agent after completely dissolving, and then pipette 5mL of antifogging agent. Put the spray agent in a clean petri dish, carefully scrape it with a glass rod, place it in a 50°C oven, and dry it while reacting. Take it out after 4 hours to obtain a long-lasting glass anti-fog film.

Embodiment 3

[0020] In a 200mL beaker, weigh 50g of polyacrylic acid with a molecular weight of 3000, 6.0g of diethanolamine, and 8.0g of sodium hydroxide, and add them to 36.0g of deionized water in order, and obtain an antifogging agent after completely dissolving, and then pipette 5mL of antifogging agent. Put the spray agent in a clean petri dish, carefully scrape it with a glass rod, place it in a 60°C oven, and dry it while reacting, take it out after 3 hours, and make a long-lasting glass anti-fog film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com