Direct connection type process for iron making and steel making interface

A direct-connection and process-based technology, which is applied to furnaces, blast furnace details, manufacturing converters, etc., can solve the problems of high headroom, heavy plant load, and large investment, so as to reduce smoke pollution, reduce project land occupation, and improve comprehensive benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

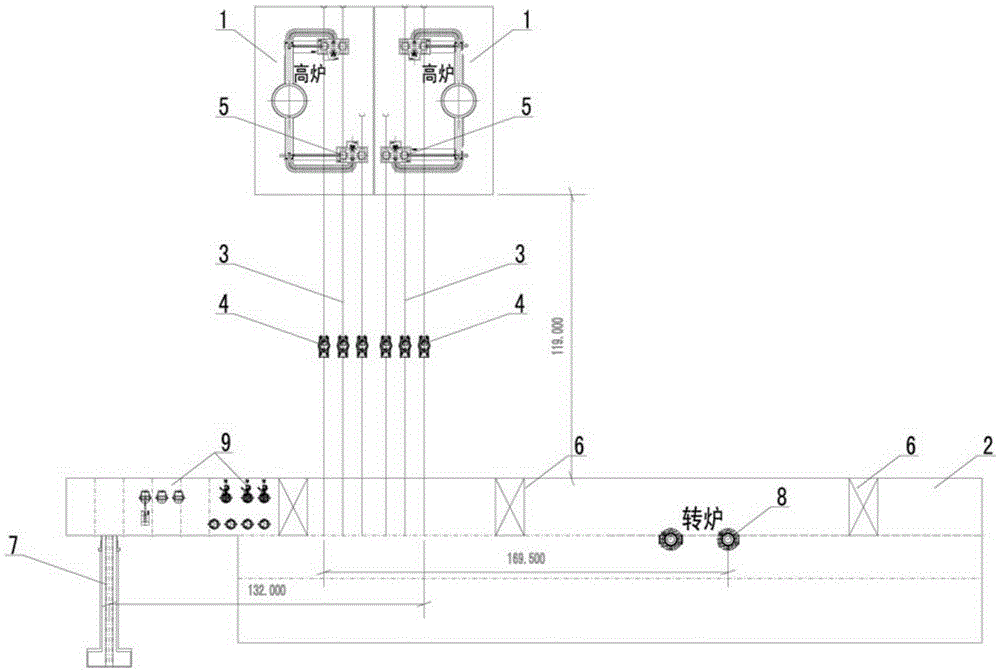

[0017] figure 1 It is a specific embodiment of the present invention.

[0018] As shown in the figure, the ironmaking workshop 1 and the steelmaking workshop 2 are directly connected through the molten iron transportation line 3, and the molten iron tank transport vehicle 4 consigns the molten iron tank under the blast furnace through the control of the weighing liquid level gauge 5 to carry out accurate iron receiving. , the molten iron tank transport vehicle 4 goes straight on the molten iron transportation line 3 to the feeding span of the steelmaking workshop 2, the distance between the side column of the casting yard and the side column of the steelmaking workshop 2 is 105-160 meters, and the straight-line transportation distance of the molten iron transportation line 3 is 160 meters. ~210 meters; the crane 6 lifts the molten iron transport line 3 from the feeding span to the molten iron tank to the pretreatment station for pretreatment and then pours iron into the conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com