Dry-method hole forming filling pile structure for post-grouting matched rotary drilling rig and construction method

A technology of rotary drilling rig and dry hole forming, which is applied in foundation structure engineering, sheet pile walls, buildings, etc. It can solve the problems of long construction period, excessive slag thickness, environmental pollution, etc., and reduce preparation and treatment, reduce Project cost and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

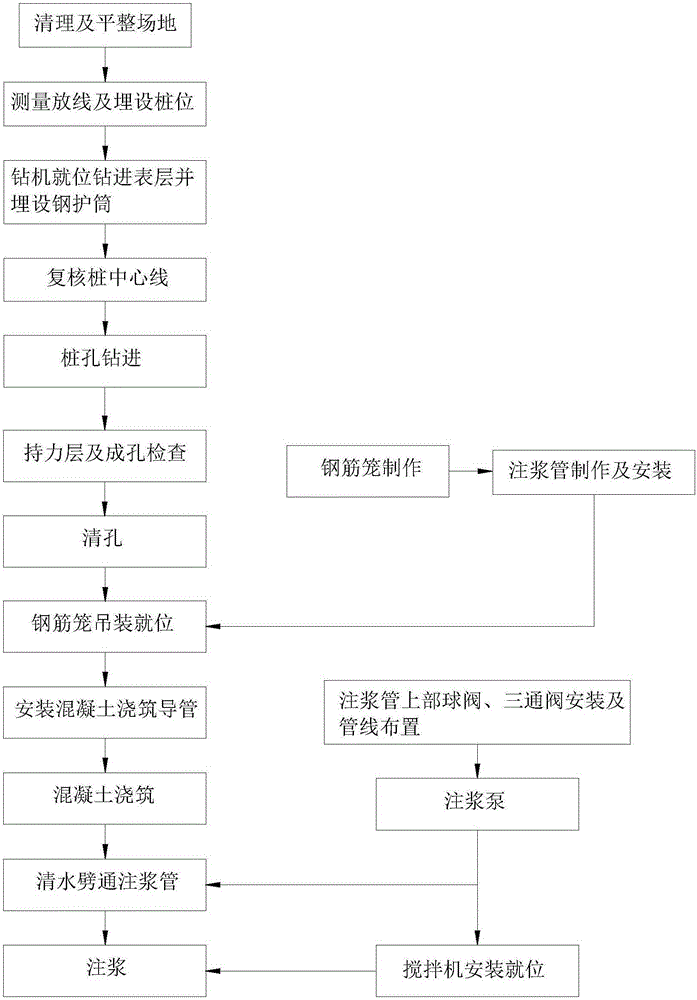

[0082] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

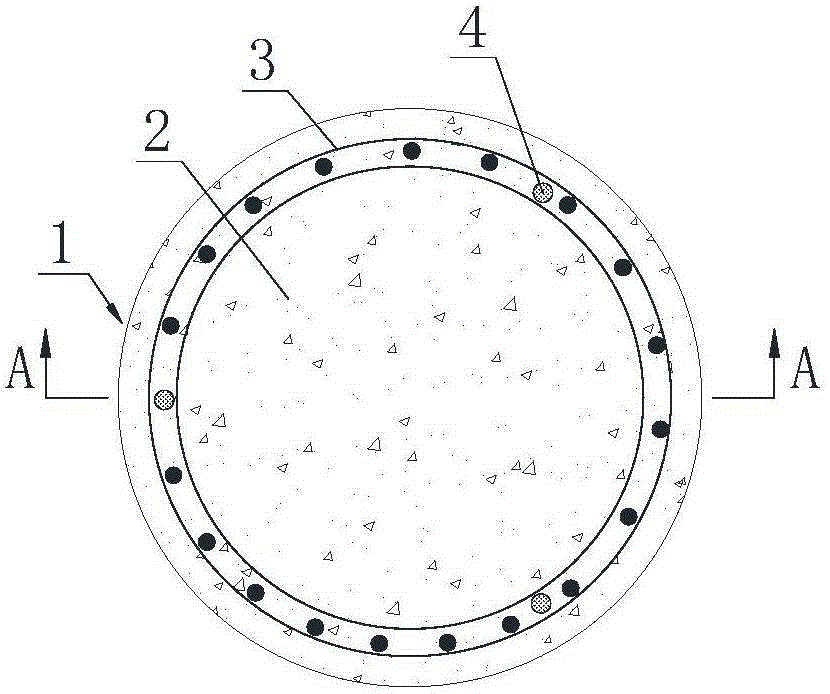

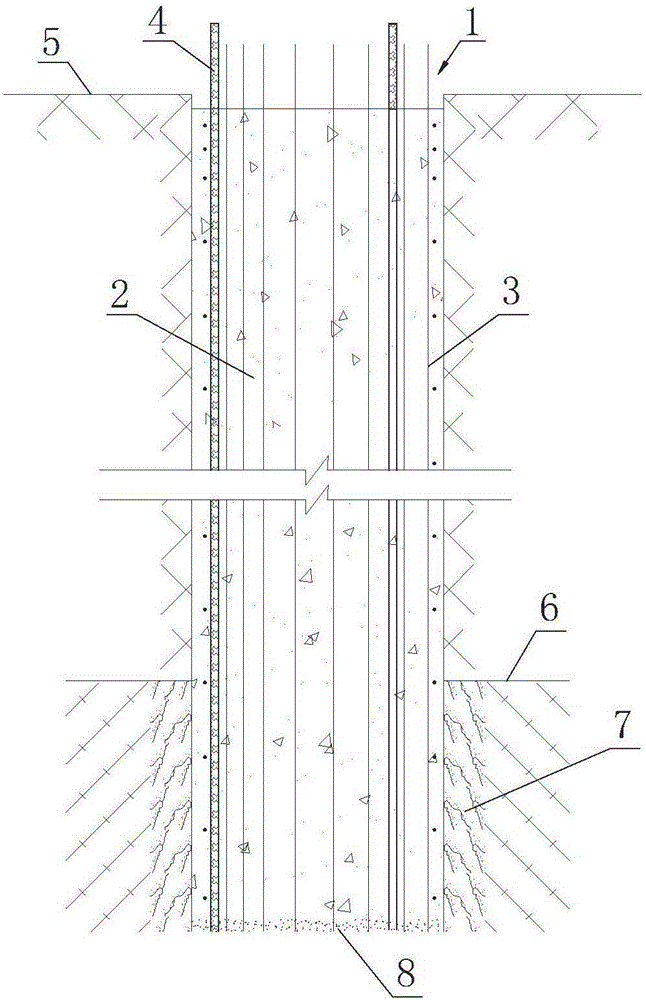

[0083] like Figure 1 to Figure 7 As shown, a post-grouting supporting rotary drilling rig dry method hole-forming cast-in-situ pile structure according to the present invention includes a hole pile body 1 arranged in the floor 5, and the hole pile body 1 is composed of concrete 2 and placed on the ground. The reinforcement cage 3 in the concrete 2 is composed of a reinforcement cage 3 that is evenly distributed into cylindrical main bars 31, and stirrup bars 32 and reinforcement hoops 33 are respectively arranged on the outside and inside of the main reinforcement 31, and the reinforcement cage 3 is along the circumferential direction Several grouting pipes 4 are evenly arranged. This technical solution arranges the grouting pipe 4 in the reinforcement cage 3, and grouts the pile tip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com