A device and method for synchronously measuring the gas-solid two-phase velocity field of a wall-attached jet

A wall-attached jet and synchronous measurement technology, which is applied in the direction of fluid velocity measurement, measuring device, velocity/acceleration/impact measurement, etc., can solve the problem that gas-solid two-phase particles cannot be separated, two-phase particles are difficult to distinguish, and errors are easily caused, etc. problems, to achieve the effect of improving utilization efficiency, balancing temperature distribution, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

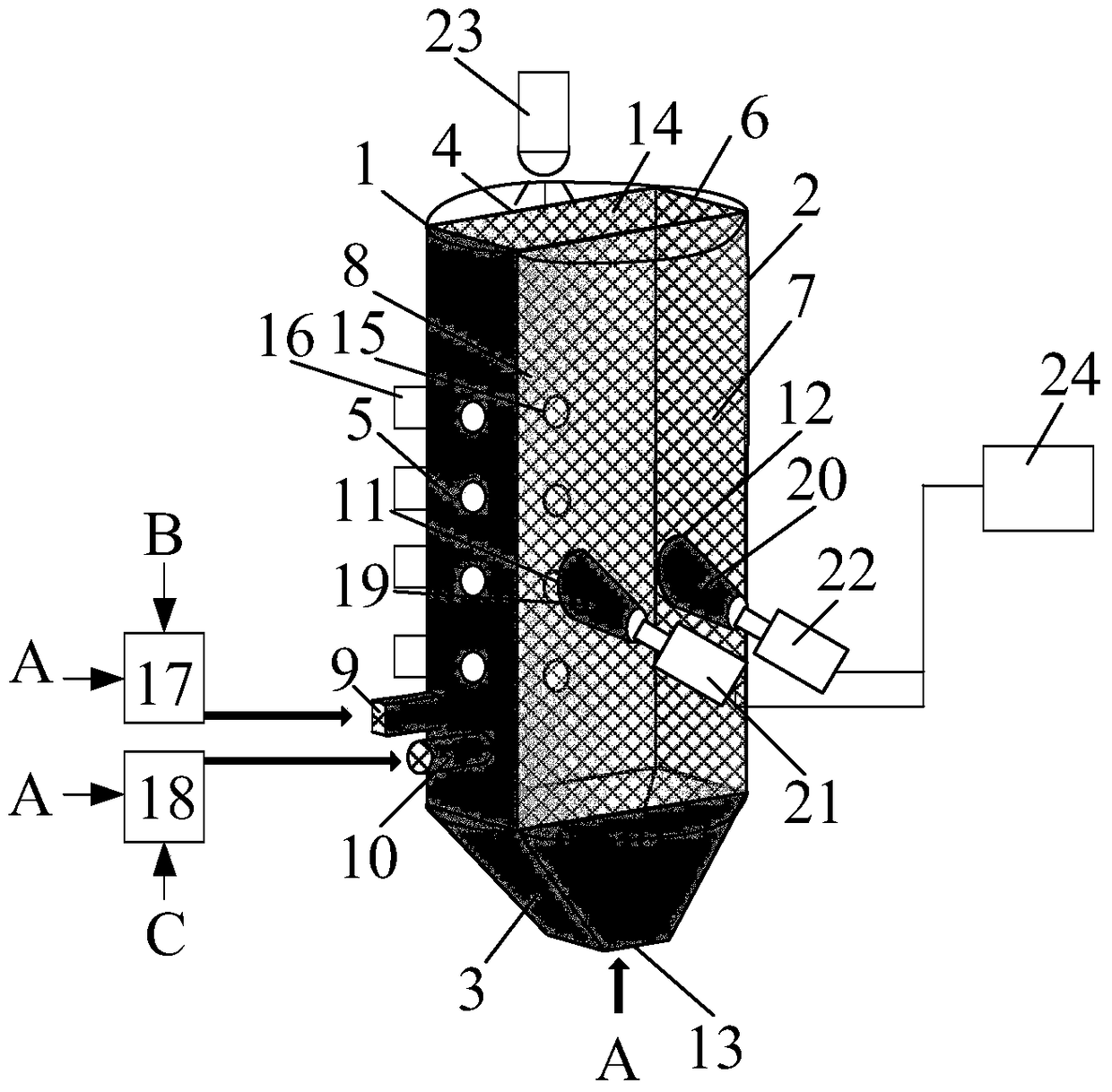

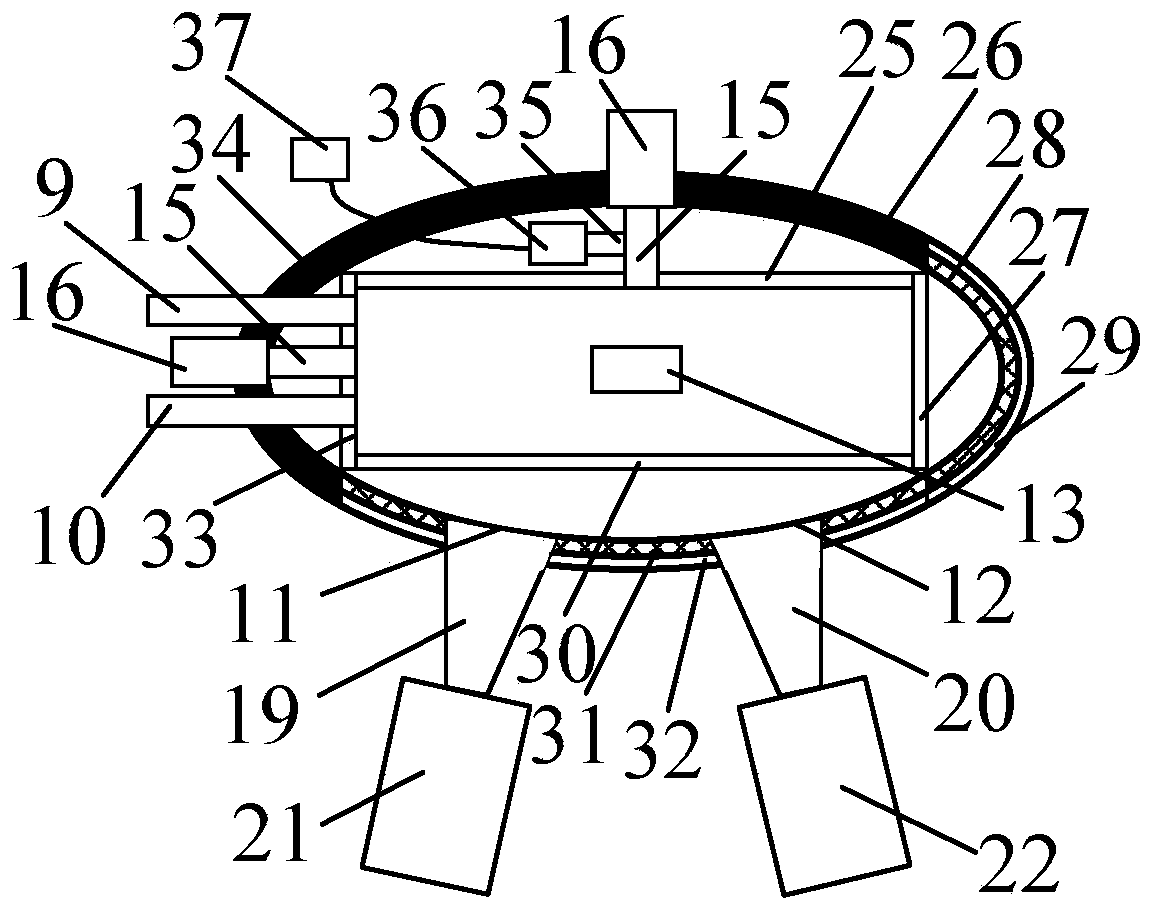

[0036] The invention proposes a synchronous measurement device for the gas-solid two-phase velocity field of the wall-attached jet, including a pulverized coal furnace modeling device, a translation device, a waveguide, a microwave transmitter, an infrared wide-angle lens, a visible wide-angle lens, a high-speed CCD camera, an infrared thermal Imager, pulsed laser sheet light source, polar particles, fluorescent particles, fluorescent particle homogenization chamber, polar particle homogenization chamber and computer. Among them, the modularized device of the pulverized coal furnace is composed of a straight section and a cone section connected up and down. There are inner lining, middle lining and outer lining respectively. Among them, the inner lining of the front plate is flat and made of sapphire infrared glass with a size of W×H; D. 1 =1.2~1.3W, arc angle β 1 =110~130°, aperture d 1 =1~2mm, opening ratio η 1 =30~40%, where W is the width of the inner lining, H is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com