Jujungrass Seedling Preparation Machine

A technology of giant fungus grass and preparation machine, which is applied to cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of not being able to meet the requirements of giant fungus grass promotion and mechanized planting, unsafe, dangerous, etc., and achieve the convenience of mechanization The effect of planting, low labor intensity, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

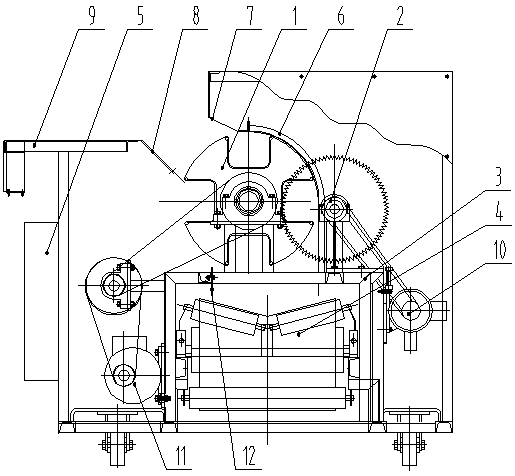

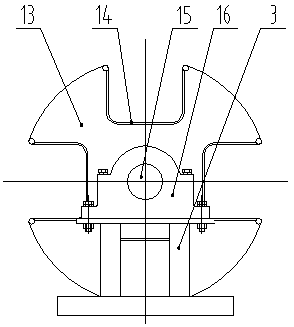

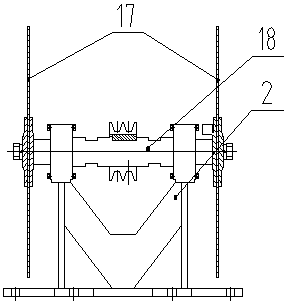

[0027] Such as figure 1 As shown, the present invention mainly comprises feeding mechanism 1, cutting mechanism 2, mounting frame 3, and feeding mechanism 1, cutting mechanism 2 are installed on the mounting frame 3, and described cutting mechanism 2 places feeding mechanism 1 side, and described cutting mechanism The saw blade 17 on the 2 is placed between the two material guide disks 13 on the feed mechanism 1, and the saw teeth of the saw blade 17 at least extend into the bottom of the material guide groove 14 on the material guide disk 13 or the bottom edge of the material guide groove 14. Coincidentally, the saw blade 17 rotates in the opposite direction to the material guide disc 13, and the feeding mechanism 1 sends the sectioned giant fungus seedlings into the collecting tank through the cutting mechanism 2 or outputs through the conveying mechanism 4.

[0028] The feeding mechanism 1 comprises a reduction motor 11, 10 material guide disks 13 arranged side by side, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com