Method for preparing drug sustained-release coating by vacuum cold spray coating technology and product prepared by method

A technology for preparing medicines and vacuum cooling, which is applied in coating, surgery, medical science, etc., can solve the problems of lack of biological activity and osteoinductive performance, and achieve the effect of low cost, high bonding strength and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

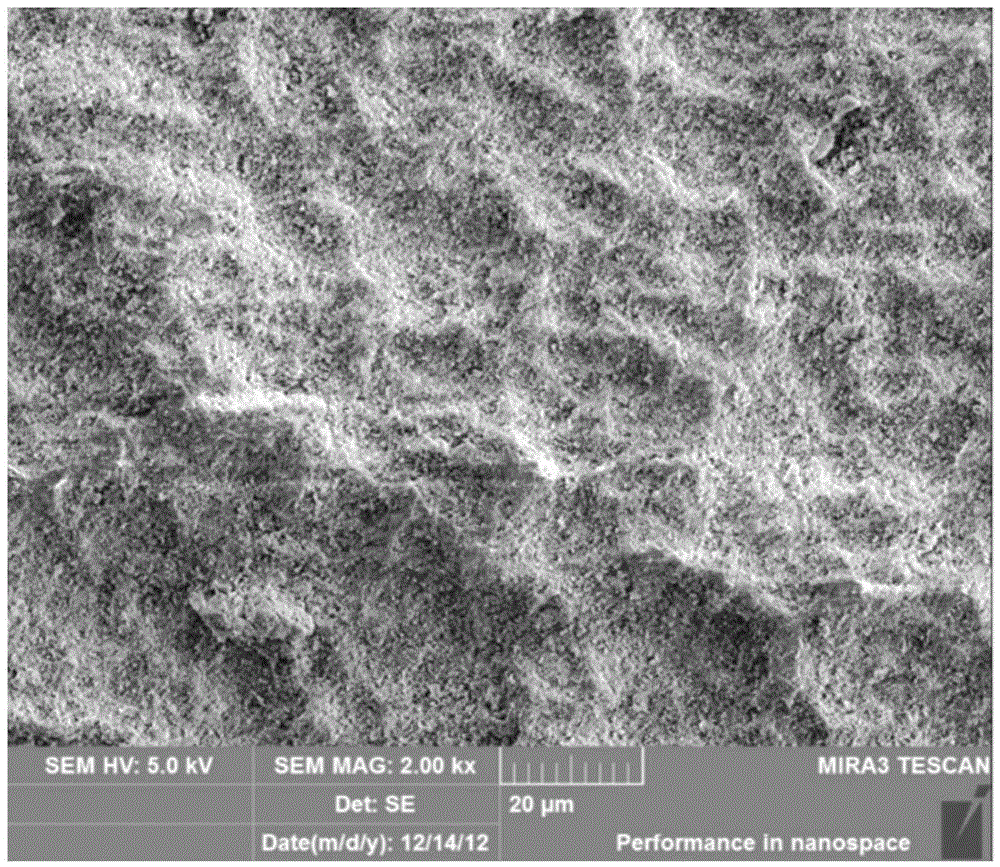

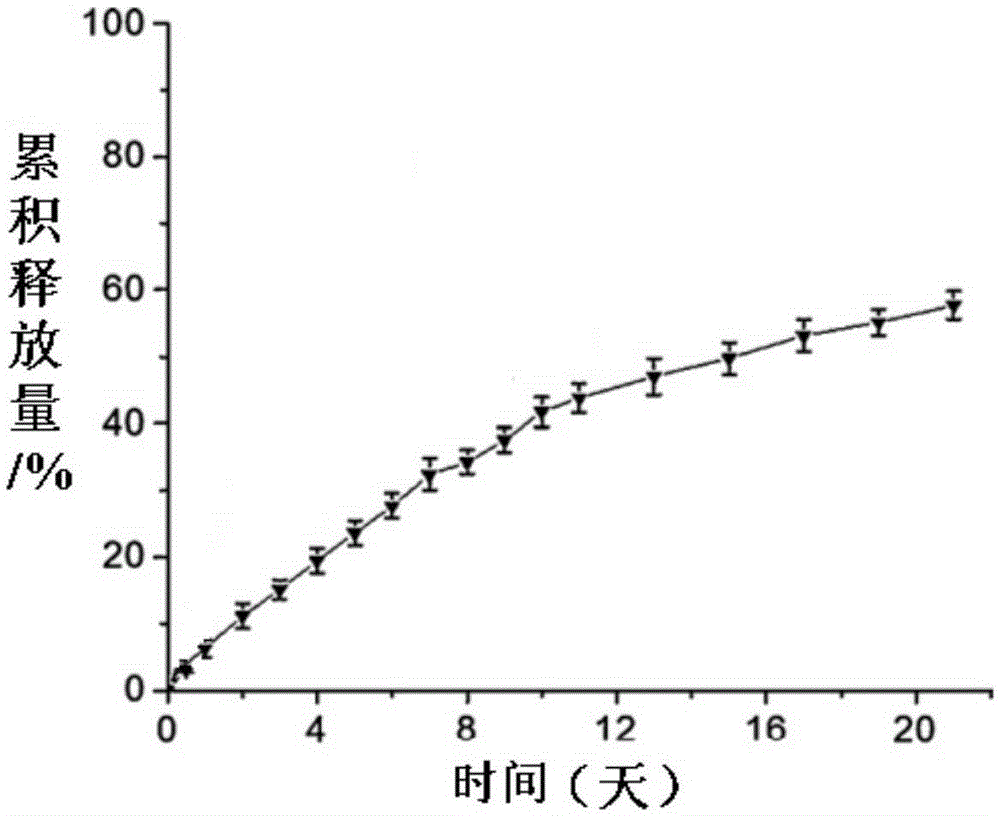

[0027] In this embodiment, the base material is a 2×2mm titanium sheet, and the obtained slow-release coating is well combined with the base material. The specific preparation method of slow-release coating is as follows:

[0028] (1) Clean the substrate with acetone, alcohol, and deionized water in sequence. After drying, use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.5MPa, and the blasting time is 30s;

[0029] (2) Preparation of HA: under stirring conditions, an equal volume of (NH 4 ) 2 HPO 4 The solution was added dropwise to 2.5mol / L Ca(NO 3 ) 2 solution, and then adjust the pH value of the mixed solution to between 10 and 11 with ammonia water, age the resulting flocculent precipitate for 7 days, wash the precipitate with deionized water until pH = 7, and dry the precipitate to obtain HA , the particle size is about 600nm.

[0030] (3) Drug (gentamycin) and HA are added in PBS (phosphate buffere...

Embodiment 2

[0034] In this embodiment, the base material is a 2×2mm titanium sheet, and the coating is well bonded to the base material. The specific preparation method of slow-release coating is as follows:

[0035] (1) Clean the substrate with acetone, alcohol, deionized water, etc. in sequence, and use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.5MPa, and the blasting time is 30s;

[0036] (2) Add the drug (gentamycin) and titanium dioxide to PBS, and stir at room temperature for 30 minutes to compound. In the obtained solution, the concentration of gentamicin is 0.001g / mL, and the concentration of titanium dioxide is 0.1g / mL, washed with deionized water, centrifuged and freeze-dried to obtain drug-loaded titanium dioxide with an average particle size of 800nm.

[0037] (4) Spray the drug-loaded titanium dioxide onto the treated substrate surface using vacuum cold spraying technology. The process parameters for cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com