Light-colored asphalt cement and preparation method thereof

A kind of asphalt glue, light-colored technology, applied in the field of light-colored asphalt binder and its preparation, can solve the problems of poor high-temperature stability, insufficient low-temperature crack resistance, etc., and achieve good low-temperature ductility, high softening point, and excellent road performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

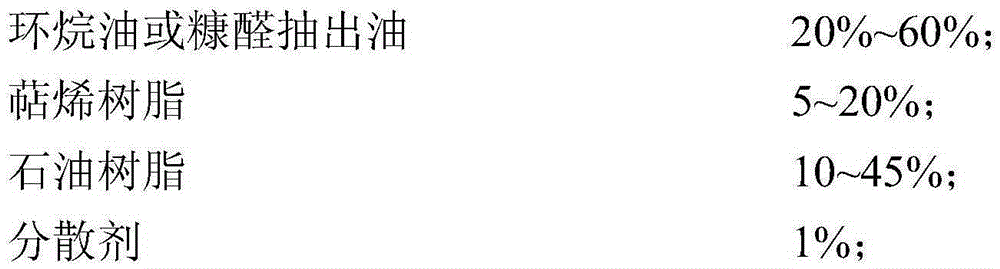

[0026] A light-colored asphalt binder, in terms of mass percentage, is made of the following raw materials:

[0027]

[0028] Wherein, the antiaging agent is composed of IrganoxB900 and o-hydroxybenzophenone in a mass ratio of 1:1; the mass content of vinyl acetate in EVA (ethylene-vinyl acetate copolymer) is 26%.

[0029] A preparation method of the above-mentioned light-colored asphalt binder, the steps are as follows:

[0030] (1) According to the above ratio, weigh a certain quality of naphthenic oil into the reaction kettle, and heat it to 150-160°C;

[0031] (2) Add a certain mass of terpene resin and C5-C9 copolymerized petroleum resin according to the predetermined composition ratio and stir fully. During the whole stirring process, control the temperature at 150°C-160°C and stir fully for 15-20min until the resin Fully soluble in naphthenic oil;

[0032] (3) Raise the temperature to 165-175°C, add linear SBS and EVA, and use high-speed shearing equipment to shear...

Embodiment 2

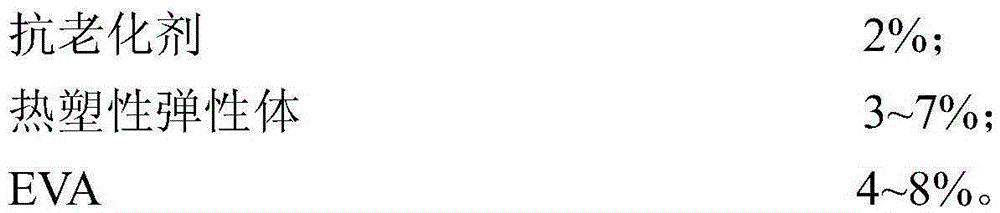

[0035] A light-colored asphalt binder, in terms of mass percentage, is made of the following raw materials:

[0036]

[0037] Wherein, the antiaging agent is composed of IrganoxB900 and o-hydroxybenzophenone in a mass ratio of 1:1; the mass content of vinyl acetate in EVA (ethylene-vinyl acetate copolymer) is 26%.

[0038] A preparation method of the above-mentioned light-colored asphalt binder, the steps are as follows:

[0039] (1) According to the above ratio, weigh a certain quality of naphthenic oil into the reaction kettle, and heat it to 150-160°C;

[0040] (2) Add a certain mass of terpene resin and C5-C9 copolymerized petroleum resin according to the predetermined composition ratio and stir fully. During the whole stirring process, control the temperature at 150°C-160°C and stir fully for 15-20min until the resin Fully soluble in naphthenic oil;

[0041] (3) Raise the temperature to 165-175°C, add linear SBS and EVA, and use high-speed shearing equipment to shear...

Embodiment 3

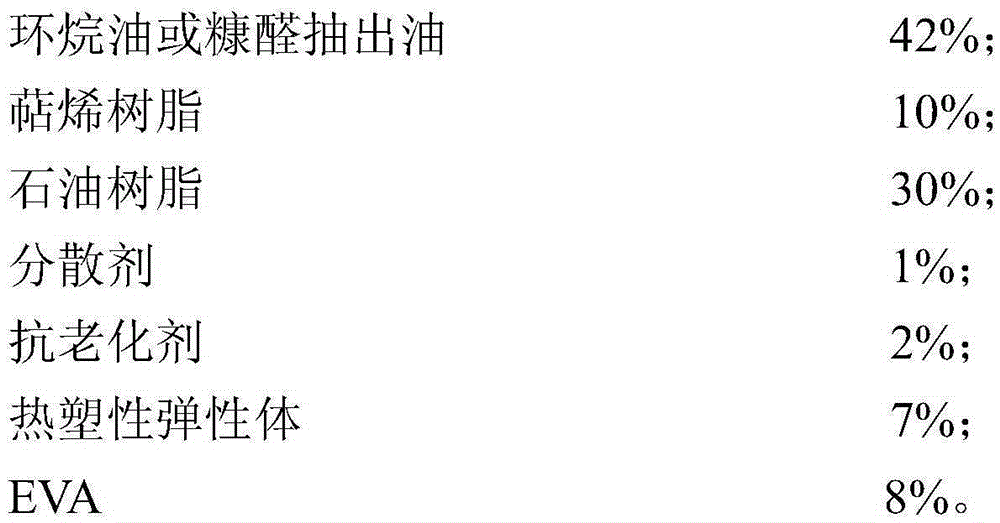

[0044] A light-colored asphalt binder, in terms of mass percentage, is made of the following raw materials:

[0045]

[0046] Wherein, the anti-aging agent is composed of IrganoxB900 and o-hydroxybenzophenone in a mass ratio of 1:1; the mass content of vinyl acetate in EVA (ethylene-vinyl acetate copolymer) is 26%.

[0047] A preparation method of the above-mentioned light-colored asphalt binder, the steps are as follows:

[0048] (1) According to the above ratio, weigh a certain quality of naphthenic oil into the reaction kettle, and heat it to 150-160°C;

[0049] (2) Add a certain mass of terpene resin and C5-C9 copolymerized petroleum resin according to the predetermined composition ratio and stir fully. During the whole stirring process, control the temperature at 150°C-160°C and stir fully for 15-20min until the resin Fully soluble in naphthenic oil;

[0050] (3) Raise the temperature to 165-175°C, add linear SBS and EVA, and use high-speed shearing equipment to shear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com