A kind of low temperature recycled asphalt mixture and its preparation method

A technology of asphalt mixture and waste asphalt mixture, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of waste of petroleum resources, short half-life of foamed asphalt regeneration technology, and slow strength increase, so as to realize the recycling of resources , good osmotic solubility, convenient transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

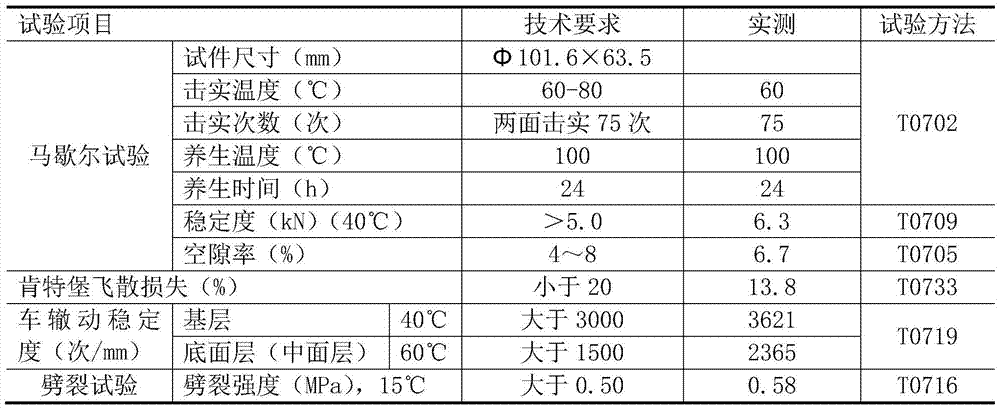

Embodiment 1

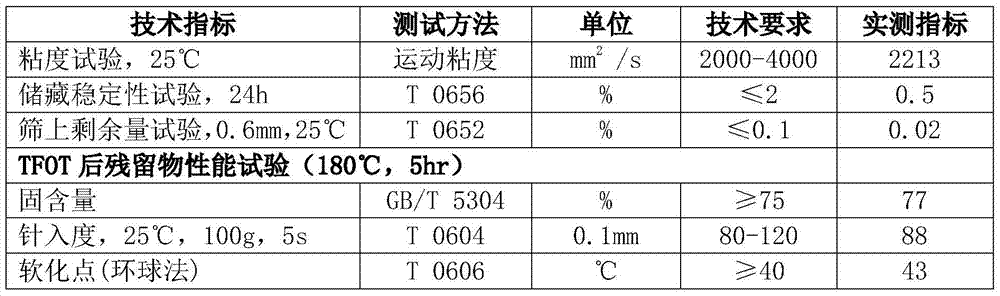

[0030]1. Preparation process of low-temperature recycled asphalt binder: use emulsified asphalt equipment unit (or equipment with forced mixing performance) to produce, first heat 70# asphalt to 130-140°C in the asphalt tank, and flow through the flow meter at 60 parts Proportional output. In the aromatic hydrocarbon oil solvent tank, add 1 part of SBS modifier and 0.3 parts of surfactant in sequence, stir thoroughly for 10 minutes, output through the flow meter at a flow ratio of 40 parts, and grind and mix with asphalt through a colloid mill (or forced mixing equipment) , and then through the cooling equipment to cool the mixture to below 90°C, the low-temperature recycled asphalt binder is obtained, and the technical indicators are shown in Table-1.

[0031] Table-1 Technical indicators of low temperature recycled asphalt binder

[0032]

[0033] It can be seen from Table 1 that the kinematic viscosity of the regenerant is 2200mm at 25°C 2 / s, has good liquidity, and a...

Embodiment 2

[0043] 1. Preparation process of low-temperature recycled asphalt binder: use emulsified asphalt equipment unit (or equipment with forced mixing performance) to produce, first heat 70# asphalt to 130-140°C in the asphalt tank, and flow through the flow meter at 65 parts Proportional output. In the aromatic hydrocarbon oil solvent tank, add 2 parts of SBS modifier and 0.4 parts of surfactant in sequence, stir thoroughly for 10 minutes, output through the flow meter at a flow ratio of 35 parts, and grind and mix with asphalt through a colloid mill (or forced mixing equipment) , and then cool the mixture to below 90°C through cooling equipment to obtain a low-temperature recycled asphalt binder. The technical indicators are shown in Table-4.

[0044] Table-4 Technical indicators of low temperature recycled asphalt binder

[0045]

[0046] It can be seen from Table-4 that the kinematic viscosity of the regenerant is 2785mm at 25°C 2 / s, has good liquidity, and all indicators ...

Embodiment 3

[0052] 1. Preparation process of low-temperature recycled asphalt binder: use emulsified asphalt equipment unit (or equipment with forced mixing performance) to produce, first heat 70# asphalt to 130-140°C in the asphalt tank, and flow through the flow meter at 70 parts Proportional output. In the aromatic hydrocarbon oil solvent tank, add 3 parts of SBS modifier and 0.5 parts of surfactant in sequence, stir thoroughly for 10 minutes, output through the flow meter at a flow ratio of 30 parts, and grind and mix with asphalt through a colloid mill (or forced mixing equipment) , and then through the cooling equipment to cool the mixture to below 90°C, the low-temperature recycled asphalt binder is obtained, and the technical indicators are shown in Table-6.

[0053] Table-6 Technical indicators of low temperature recycled asphalt binder

[0054]

[0055] It can be seen from Table-6 that the kinematic viscosity of the regenerant is 3650mm at 25°C 2 / s, has good liquidity, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com