Pile cap of prefabricated square concrete pile

A prefabricated square and concrete technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of long electric welding connection time, slow construction progress, easy to produce cracks, etc., to improve construction quality and speed, easy and fast connection , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

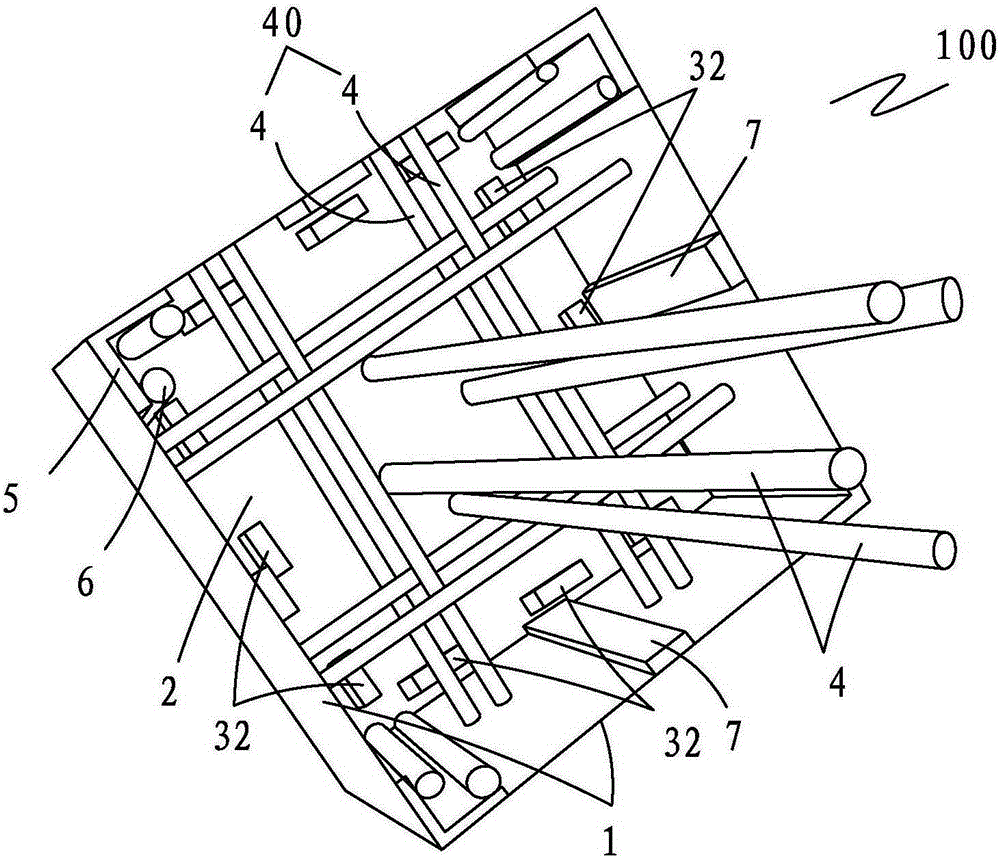

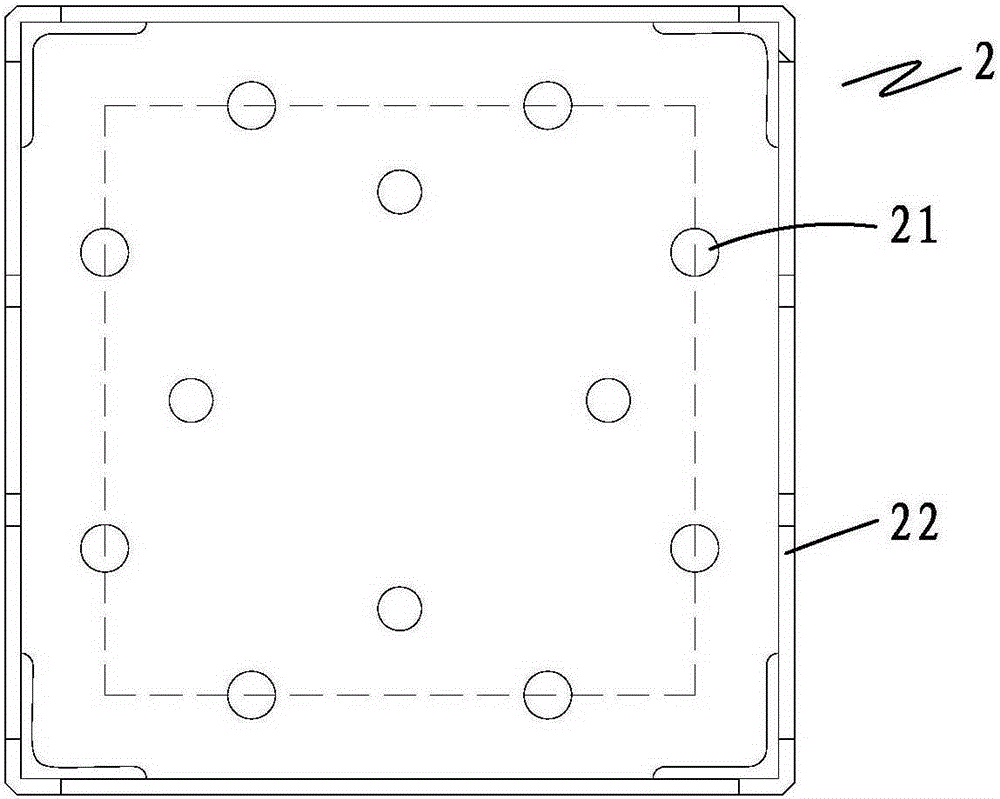

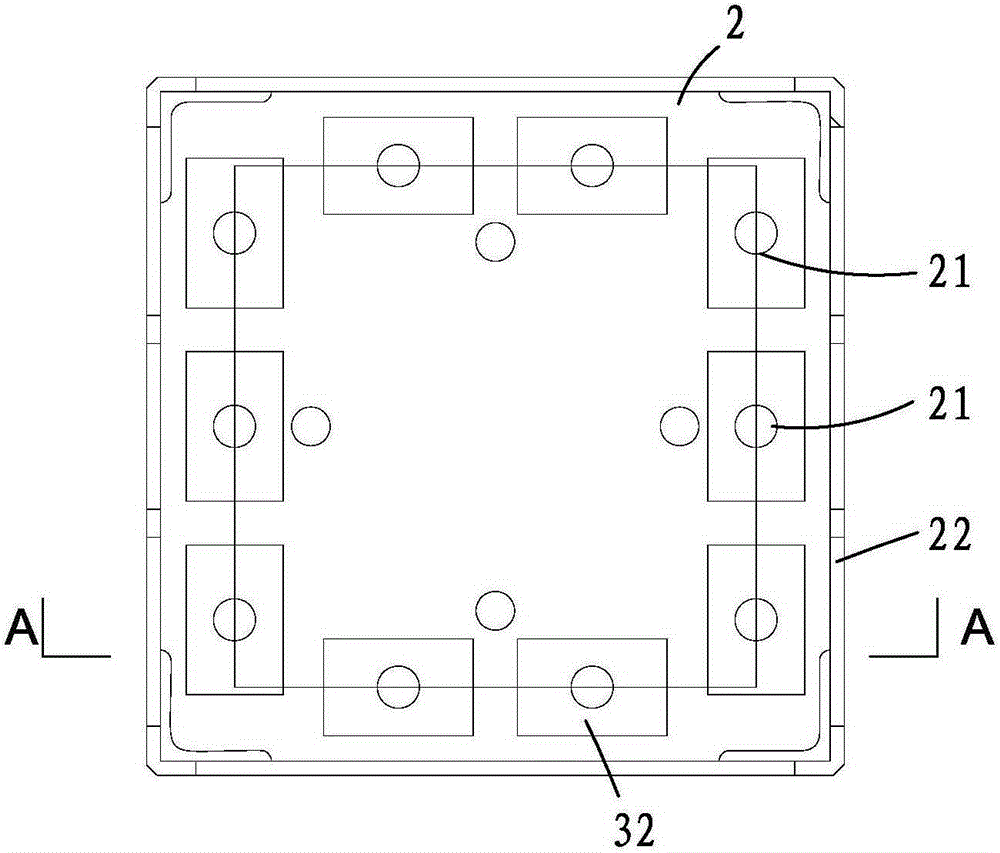

[0022] see figure 1 , figure 2 and image 3 As shown, a concrete prefabricated square pile cap 100 includes four skirt plates 1, a top plate 2 and a plurality of connectors 3, the four skirt plates 1 surround a square body, and the top plate 2 is welded to the square body The upper surface of the top plate 2 is provided with a plurality of screw holes 21; the outer edge of the upper surface of the top plate 2 is provided with an inclined surface 22, when the top plate 2 and the four skirts 1 are welded, the four edges of the top plate 2 An inclined surface 22 is provided on each side to make the welding seam bigger, the welding spot more plump, and the welding between the top plate 2 and the four skirt plates 1 is stronger. The middle part of the top plate 2 is evenly equipped with four anchor ribs 4; the four corners of the inner wall of the square are respectively welded with a right-angle member 5, and the first and last ends of the right-angle member 5 are respectively ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap