Prestressed shear wall and vertical joint combining-connecting structure and construction method thereof

A prefabricated shear force and combined connection technology, which is applied to walls, building components, building structures, etc., can solve problems affecting the integrity and mechanical performance of the connection, insufficient overall mechanical performance, easy cracking and falling, etc., to achieve Improve the ability to resist horizontal loads, good construction quality, and improve the effect of bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

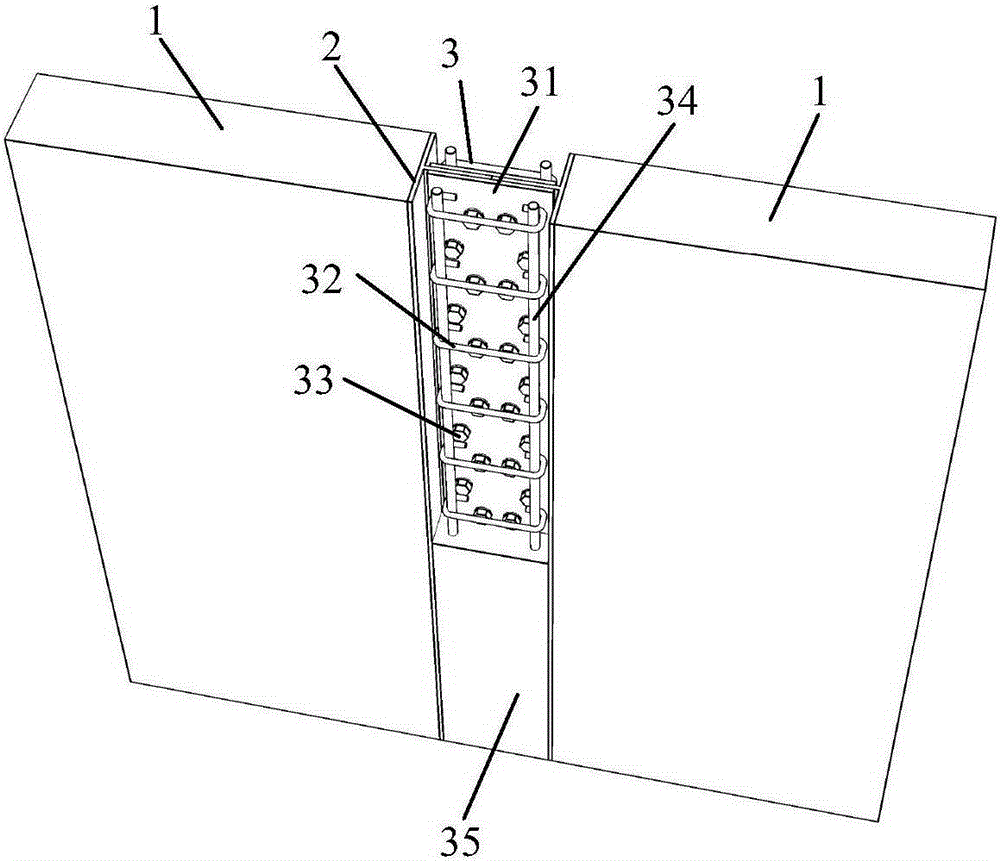

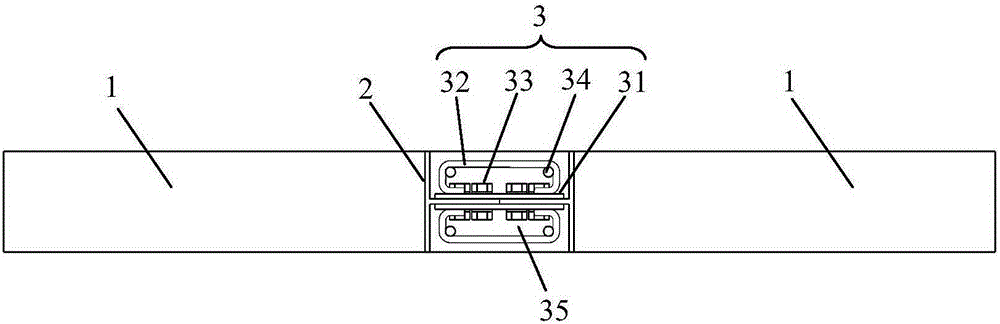

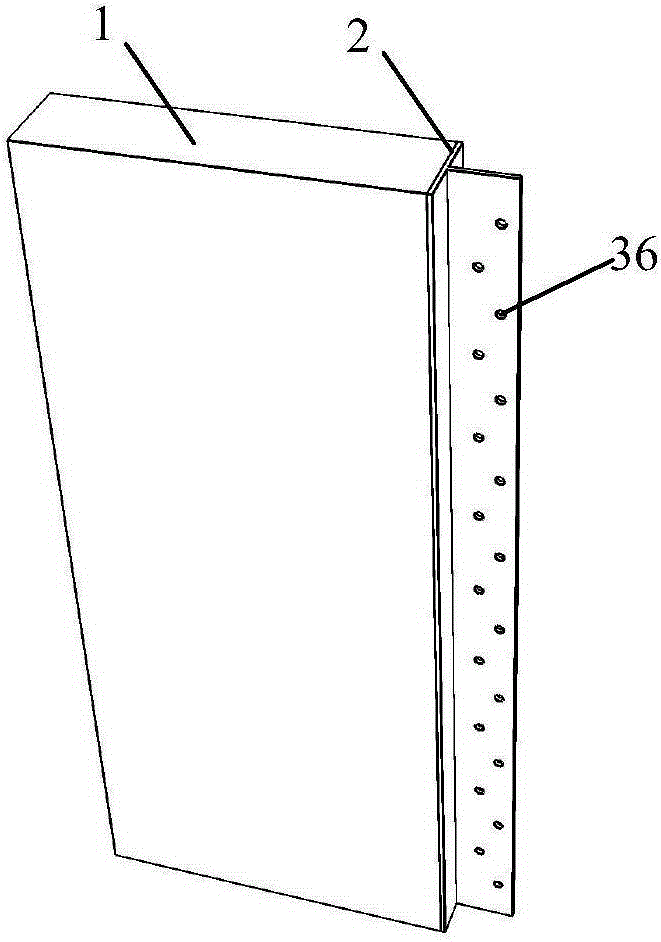

[0028] see Figure 1 to Figure 4 As shown, in order to see clearly the structure of the connection of the prefabricated shear wall vertical joint connection structure, part of the concrete is removed. A combined vertical joint connection structure of prefabricated shear walls according to the present invention comprises at least two prefabricated shear walls 1, two prefabricated steel sections 2, and a fixing component 3; On the side wall of the wall 1, the two pre-embedded steels 2 are placed between two prefabricated shear walls 1, and the fixing component 3 fixes the two pre-embedded steels 2; the fixing component 3 includes: two splints 31. A plurality of stirrups 32, a plurality of bolts 33 and at least four longitudinal reinforcements 34; the webs of the two pre-embedded shaped steels 2 are connected by the front and rear splints 31 through the bolts 33; and the pre-embedded shaped steel 2 and the front and rear two The splints 31 are arranged continuously in the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com