Refraction-based solar light homogenizing tube type reactor or dryer and design method thereof

A tubular reactor and dryer technology, which is applied to solar collectors, solar collectors, and solar thermal energy using working fluids, can solve problems such as unevenness, loss, product quality, and adverse effects on shape, and achieve The effect of uniform distribution and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

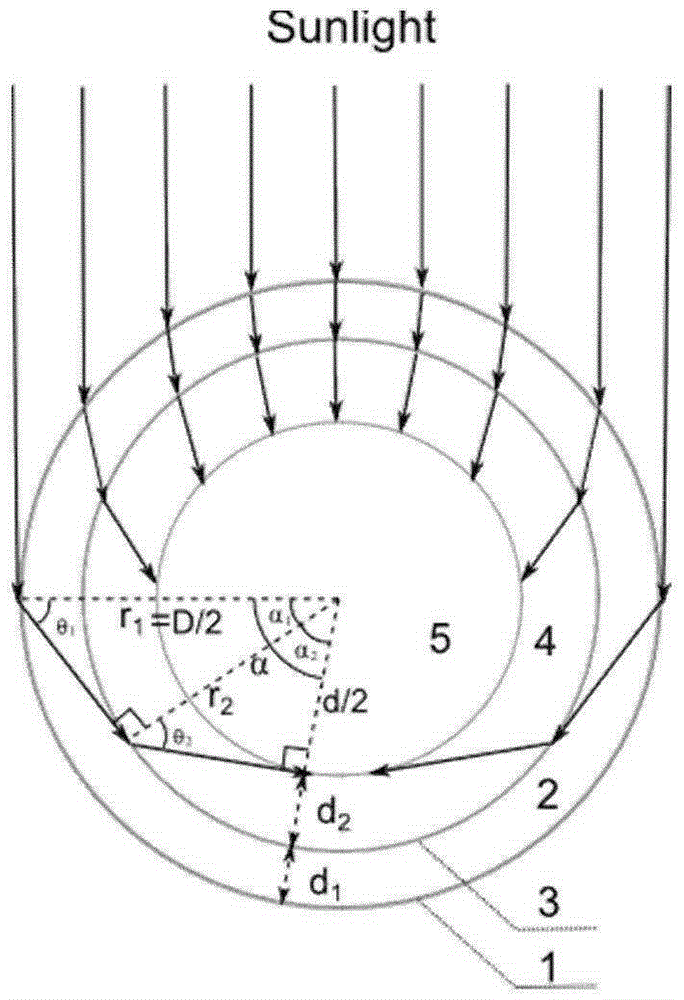

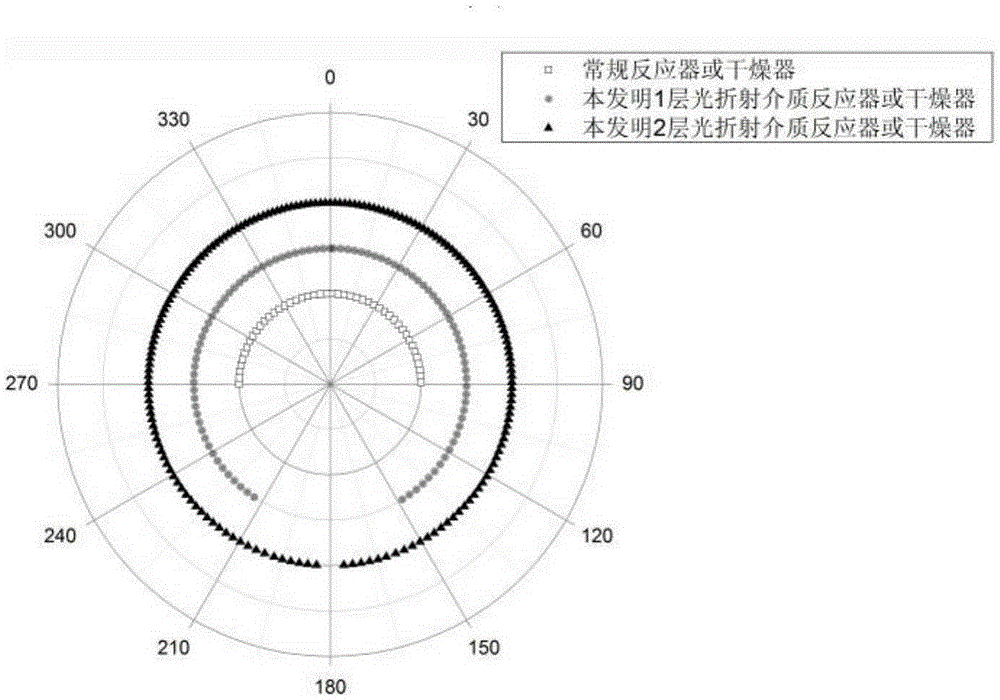

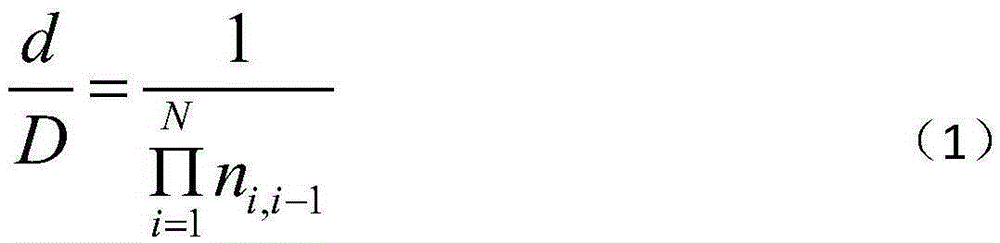

[0036] Utilize reactor or drier design and optimization method of the present invention, design has the solar energy reactor of 1 layer (N=1) light refraction medium or drier, assume that reactor or drier external diameter (D) is 4cm, the outer cover There is an anti-reflective coating to reduce the reflection loss of light. The inner diameter (d) of the dryer or reactor is 2.12cm. Under the condition of optimal light distribution, according to the formula (1):

[0037] n 1 , 0 = D d = 1.89

[0038] The thickness d of the light-refractive medium can be obtained from formula (2) 1 :

[0039] d 1 = D ( n 1 , 0 ...

Embodiment 2

[0044] Utilize the present invention to design solar reactor or drier with 2 layers (N=2) light refraction medium, assuming reactor or drier external diameter (D) is 4cm, is covered with anti-reflection film outside, reduces the reflection loss of light, The inner diameter (d) of the dryer or reactor is 2.12cm. Under the condition of optimal light distribution, according to the formula (1), it can be known that

[0045] d D = 1 Π i = 1 N n i , i - 1 = 1.06 2

[0046] From this, the refractive index of the two layers of photorefractive medium can be obtained as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com