Quartz crystal resonance sensor welded by using low-temperature glass solder and preparation method of quartz crystal resonance sensor

A low-temperature glass solder, quartz crystal oscillator technology, applied in the direction of using electric/magnetic devices to transmit sensing components, instruments, measuring devices, etc., can solve the problems of low sensitivity, unusable test conditions, low quality factor, etc., to achieve high sensitivity, Avoid laser thermal effects, high quality factor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

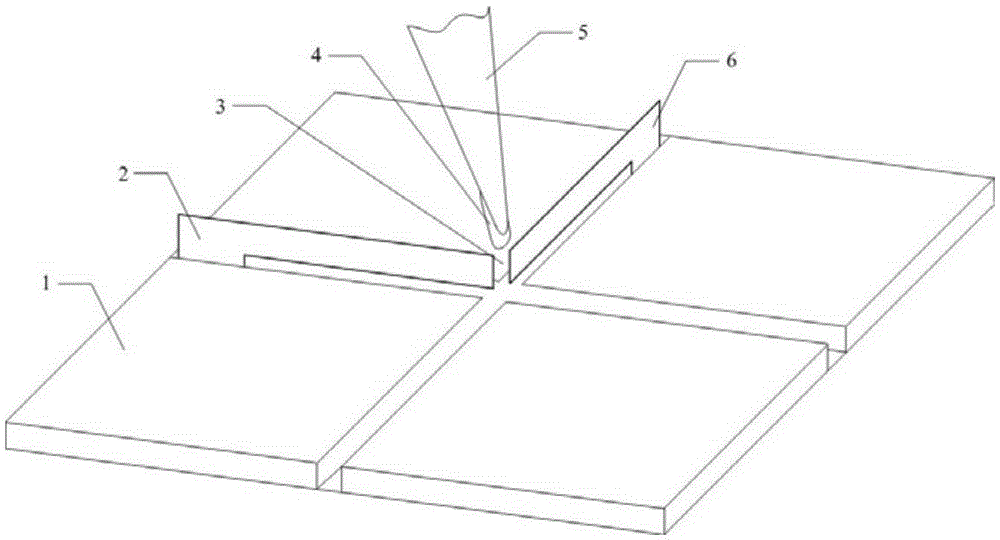

[0025] Embodiment 1: This embodiment is a quartz crystal oscillator sensor welded by low-temperature glass solder. Two or four quartz crystal oscillator cantilevers with the same size and shape are welded together by low-temperature glass solder.

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the low-temperature glass solder is low-temperature sealing glass beads, and the grade is FM-13. Others are the same as the first embodiment.

[0027] The low-temperature sealing glass beads FM-13 described in this embodiment were purchased from Beijing Tianli Chuang Glass Technology Development Co., Ltd.

specific Embodiment approach 3

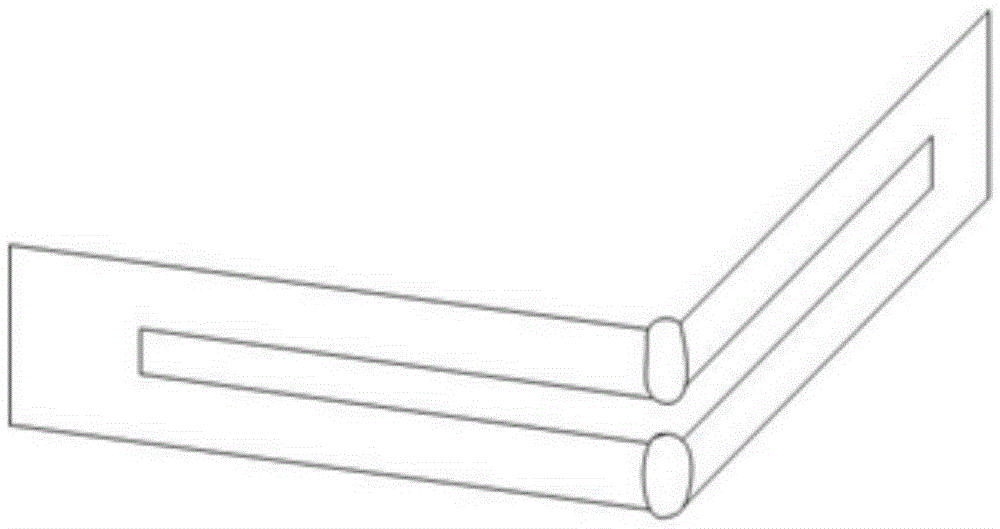

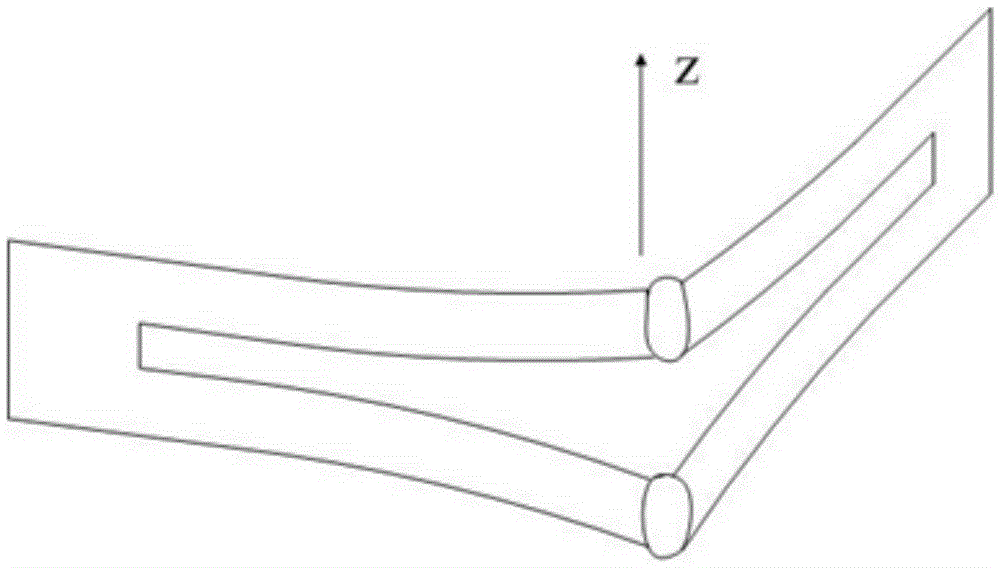

[0028]Specific embodiment three: this embodiment is that when the quartz crystal oscillator sensor welded by low-temperature glass solder is welded together by low-temperature glass solder, two quartz crystal oscillator cantilevers with the same size and shape are welded together, and it is completed according to the following steps: The two quartz crystal oscillators with the same size and shape are respectively the first quartz crystal oscillator and the second quartz crystal oscillator. The first quartz crystal oscillator and the second quartz crystal oscillator are vertically fixed on the welding table respectively, and the first quartz crystal oscillator is made The cantilever A1 arm and the first cantilever B1 arm of the second quartz crystal oscillator are at the same height, the second cantilever A2 arm of the first quartz crystal oscillator is at the same height as the second cantilever B2 arm of the second quartz crystal oscillator; The angle formed by the top of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com