High-precision zero-length spring temperature drift and long-term creep deformation detector

A zero-length spring and detector technology, applied in the testing of mechanical parts, machine/structural parts testing, instruments, etc., can solve the problem that the zero-length spring has a narrow application range, has not been put into mass production, and lacks detection methods for zero-length springs. and other problems, to achieve the effect of long-term observation, system stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0049] 1. The structure of the measuring instrument

[0050] 1. Overall

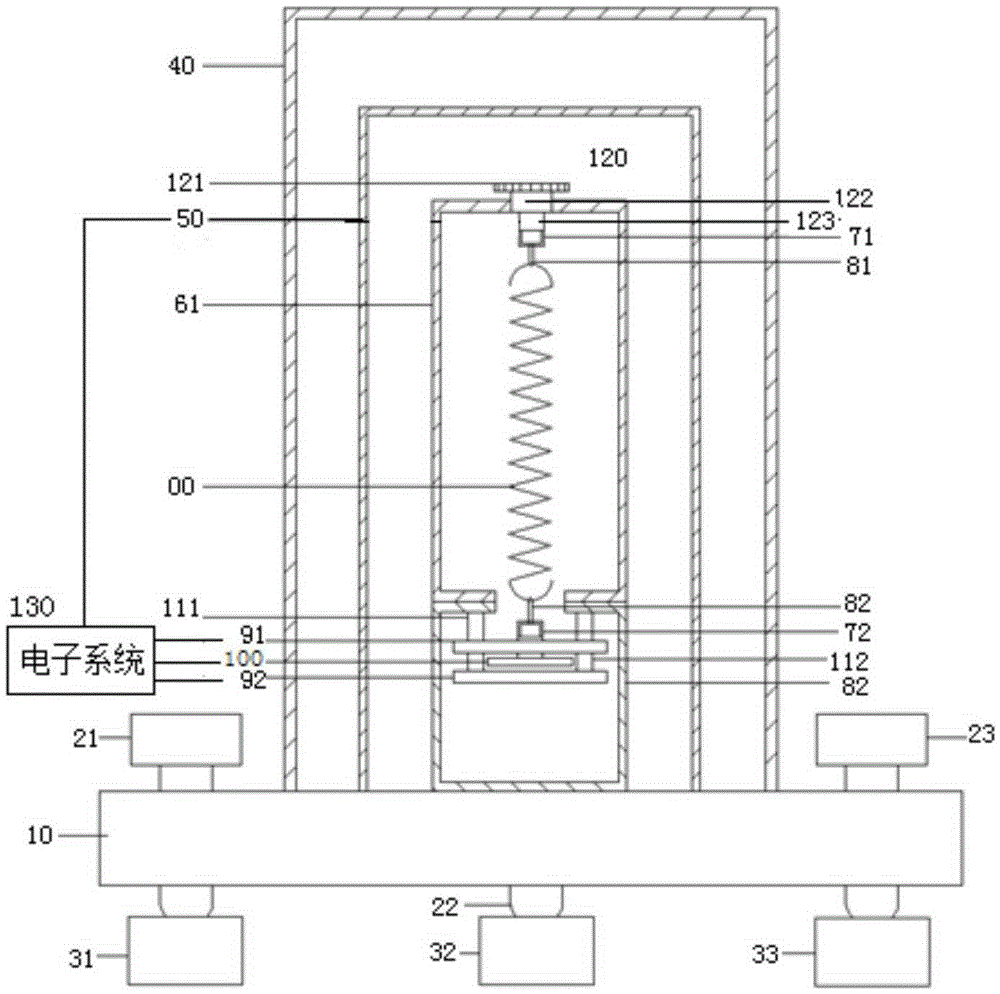

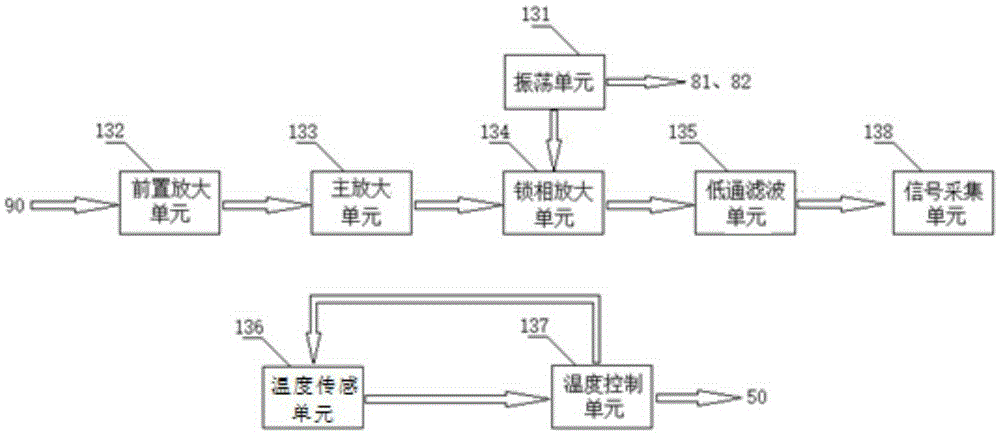

[0051] Such as figure 1 , the tester includes the measured object - zero length spring 00;

[0052] The base 10, the first, second, and third support screws 21, 22, 23, the first, second, and third pads 31, 32, and 33, the outer shell 40, the thermostatic tube 50, the spring shielding tube 61, and the supporting tube 62 are provided. Upper and lower wire sockets 71, 72, upper and lower spring hanging wires 81, 82, upper and lower capacitor stators 91, 92, capacitor moving plate 100, first and second fixed columns 111, 112, zero adjustment mechanism 120 and electronic system 130;

[0053] Its location and connection relationship are:

[0054] The first screw rod 21, the second screw rod 22 and the third screw rod 23 arranged in a triangle pass through the screw holes of the base 10 respectively and placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com