Soybean germ sugar and preparation method thereof

The technology of soybean germ and soybean germ is applied in the field of soybean germ sugar and its preparation, which can solve the problems of complicated separation and purification process and high selling price, and achieve the effects of prolonging the shelf life and improving the anti-oxidation property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The production process of soybean germ powder:

[0040] 1.1 Separation of hulls and grains: separate the given bean germ and hull, remove the hull, and leave the bean germ.

[0041] 1.2 Sieving and grading: screen the bean germ particle size according to the finished product. Select particles with a size between 10 mesh and 20 mesh.

[0042] 1.3 Washing and drying: wash the selected bean embryos in clean water, remove them, and dry them in the air.

[0043] 1.4 Baking and drying: Put the bean embryos into the oven and bake them at 140°C for 30 minutes until they have the ideal color, fragrance and crispness, and the color of the surface and center of the bean embryos is basically the same; in order to ensure uniform heating, bake Before roasting, the bean germ can be stored for a short time to balance the moisture, and the nuts in the baking tray can be spread into a thin layer to avoid accumulation and uneven heating. Then put it into a hot air stove and dry it for ...

Embodiment 2

[0045] Soybean embryo roasting pretreatment single factor experiment:

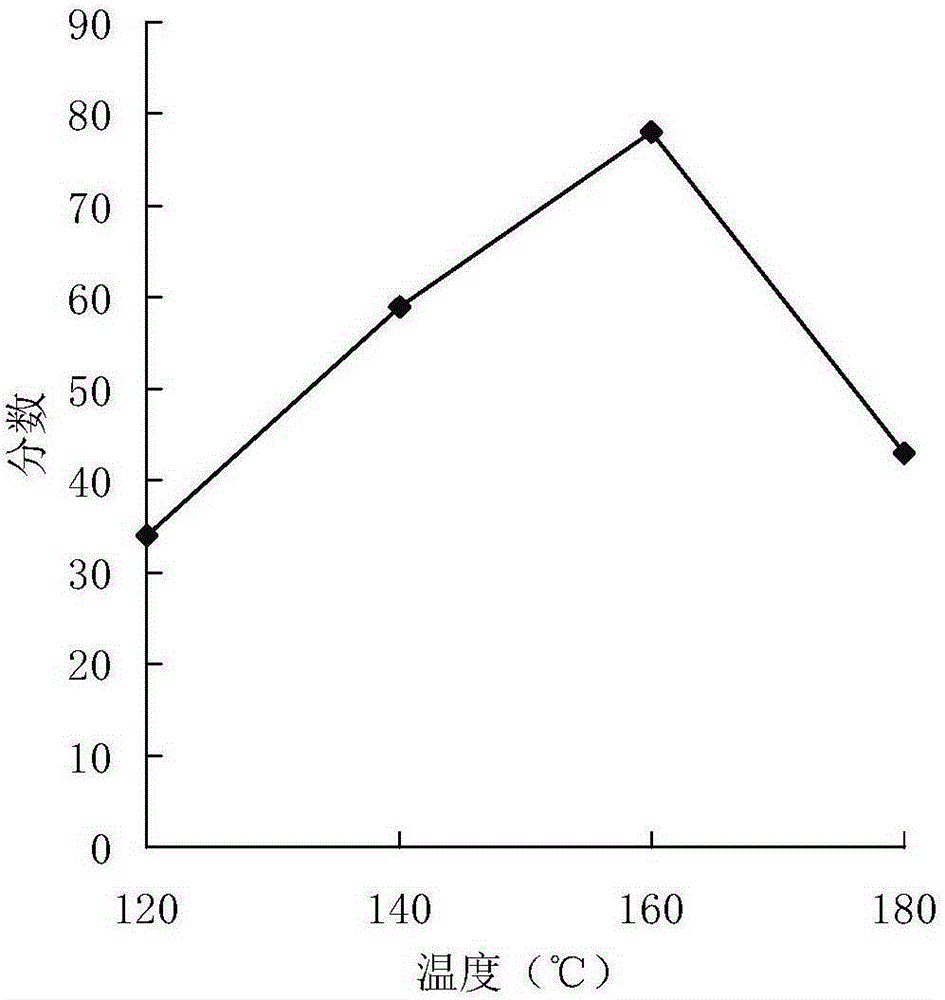

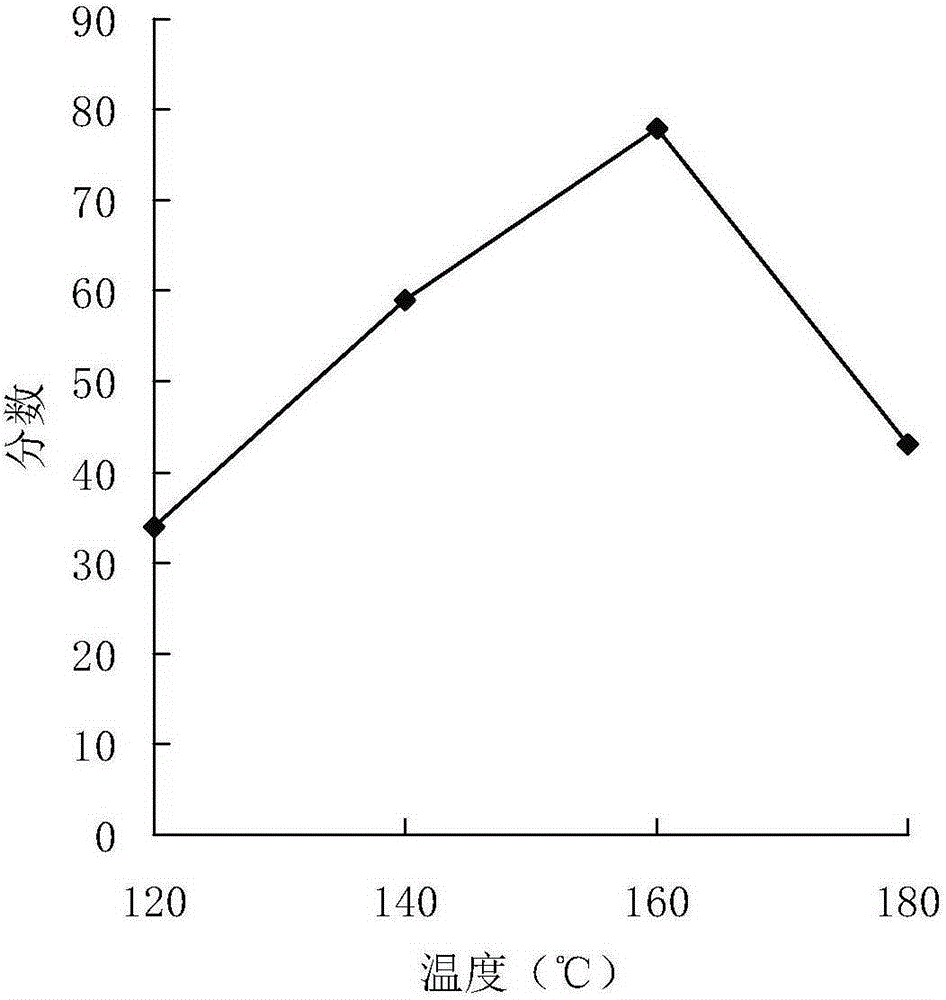

[0046] 2.1 Effects of different roasting temperatures on the quality of bean germ

[0047] A certain amount of dried soybean germ samples were weighed, placed in far-infrared ovens, and the temperatures were respectively set at 120°C, 140°C, 160°C, 180°C, and heat-treated for 30 minutes. Afterwards, the processed bean embryos are taken out and stored in a dry environment. Its color, fragrance, crispness and other qualities were observed and tested, and the sensory evaluation system was used to score it.

[0048] Depend on figure 1 It can be seen that in the range of 120°C-160°C, as the temperature increases, the sensory quality score increases almost in direct proportion. However, when the temperature rose to 180°C, it was observed in the experiment that the color of the bean embryo changed greatly, which was dark brown and had a severe burnt bitter taste. Therefore, it can be obtained that the roastin...

Embodiment 3

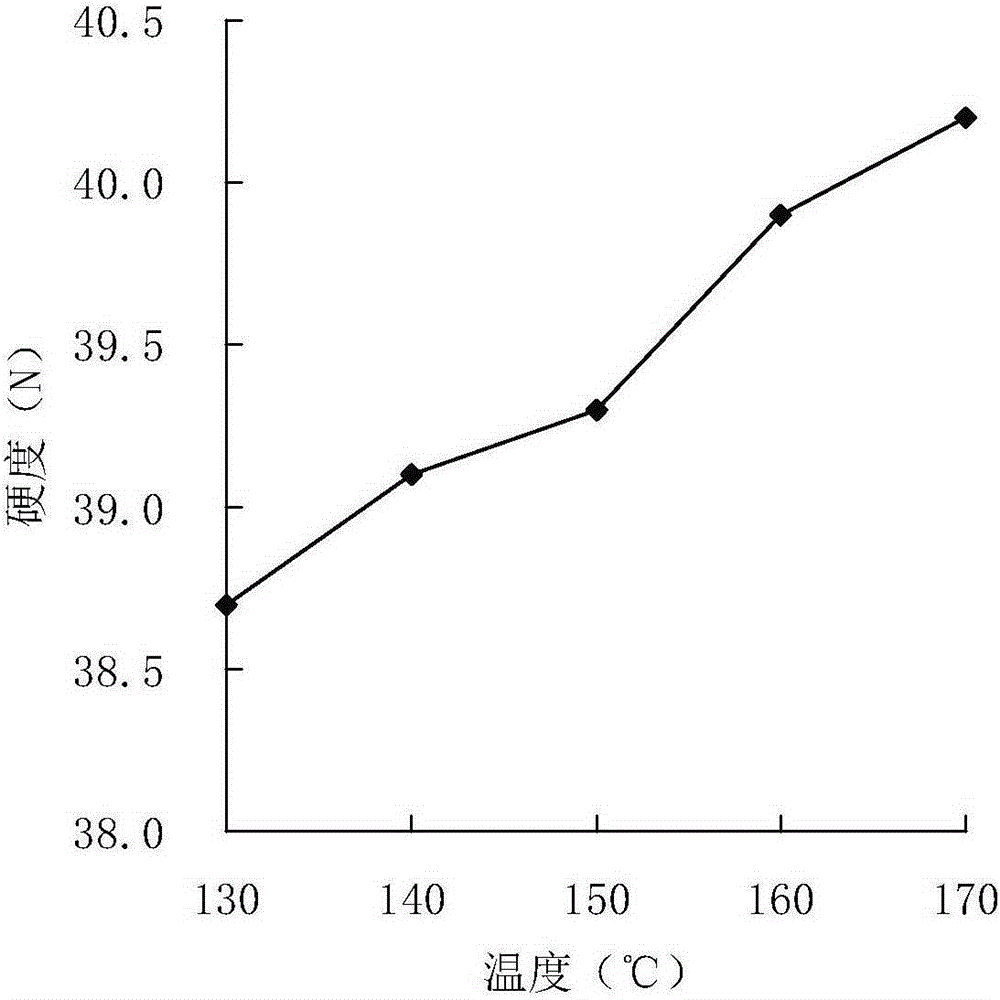

[0053] As far as the bean germ in the bean germ sugar is concerned, when the color of the soybean germ is suitable and the aroma is strong, it can arouse people's desire to eat more. And this series of qualities are the flavor substances obtained by the moderate Maillard reaction of bean germ at high temperature; in order to make the bean germ sugar have a crisp taste and good preservation, we should take certain drying methods to make the bean germ The moisture content and water activity of soybean embryos are low; from the perspective of preservation, if the soybean embryo is treated at high temperature for a long time during the drying and heat treatment process, the degree of fat cracking will be higher, the antioxidant capacity will be reduced, and the stability will be reduced , will easily form rancidity; therefore, if the moisture content in the bean germ after the final pretreatment is high, the preservability of the bean germ sugar will be reduced. Combining the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com