Multi-station production line type upper napping system and processing method thereof

An assembly line, multi-station technology, applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of high manual technical requirements, high labor intensity, low degree of process automation, etc., and achieve exquisite template design and shape positioning accuracy High and guaranteed quality uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

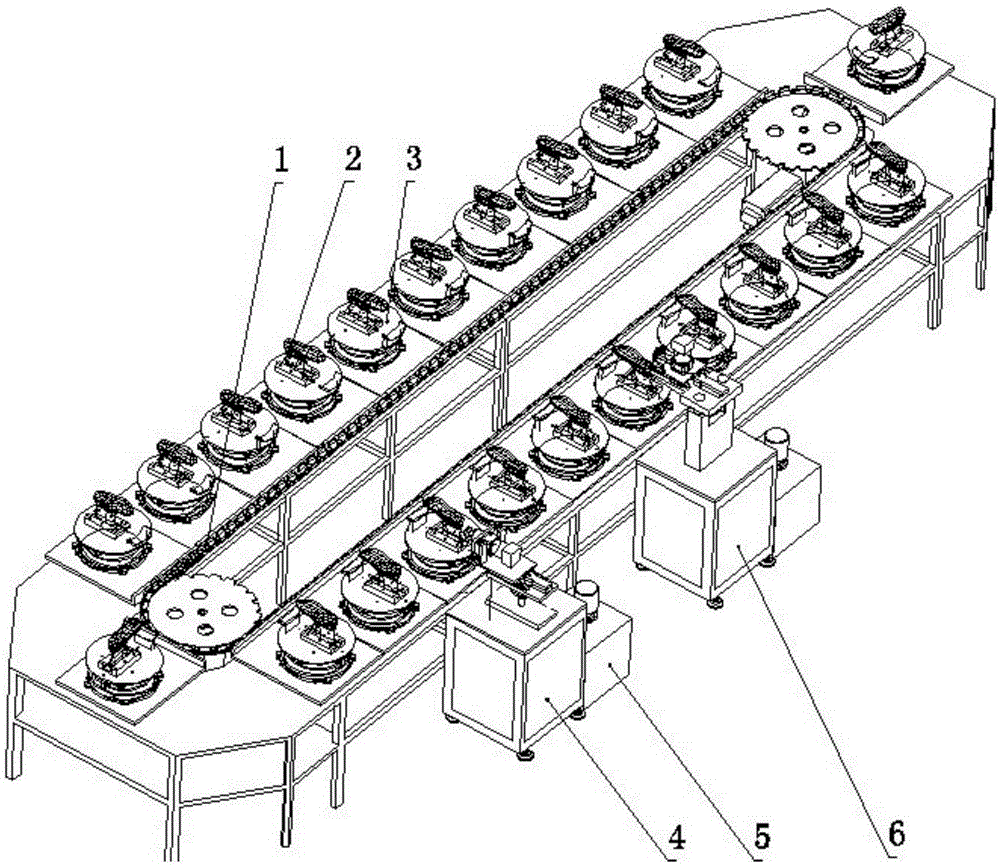

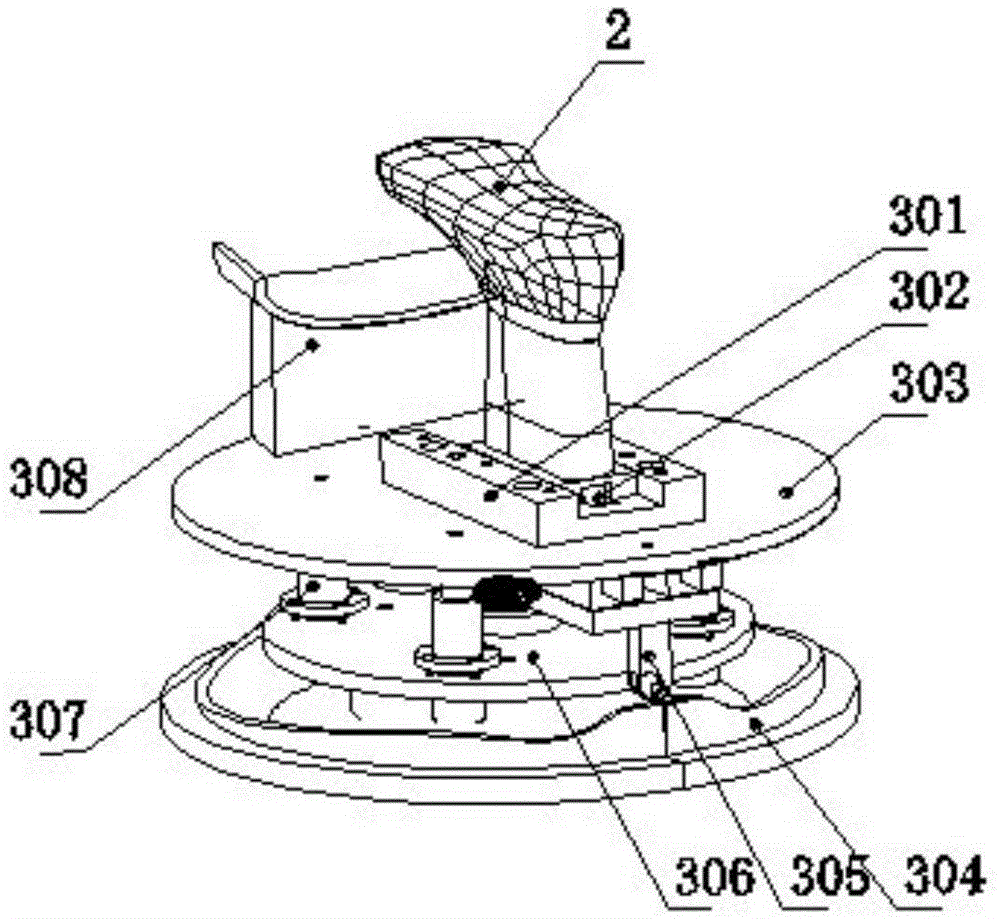

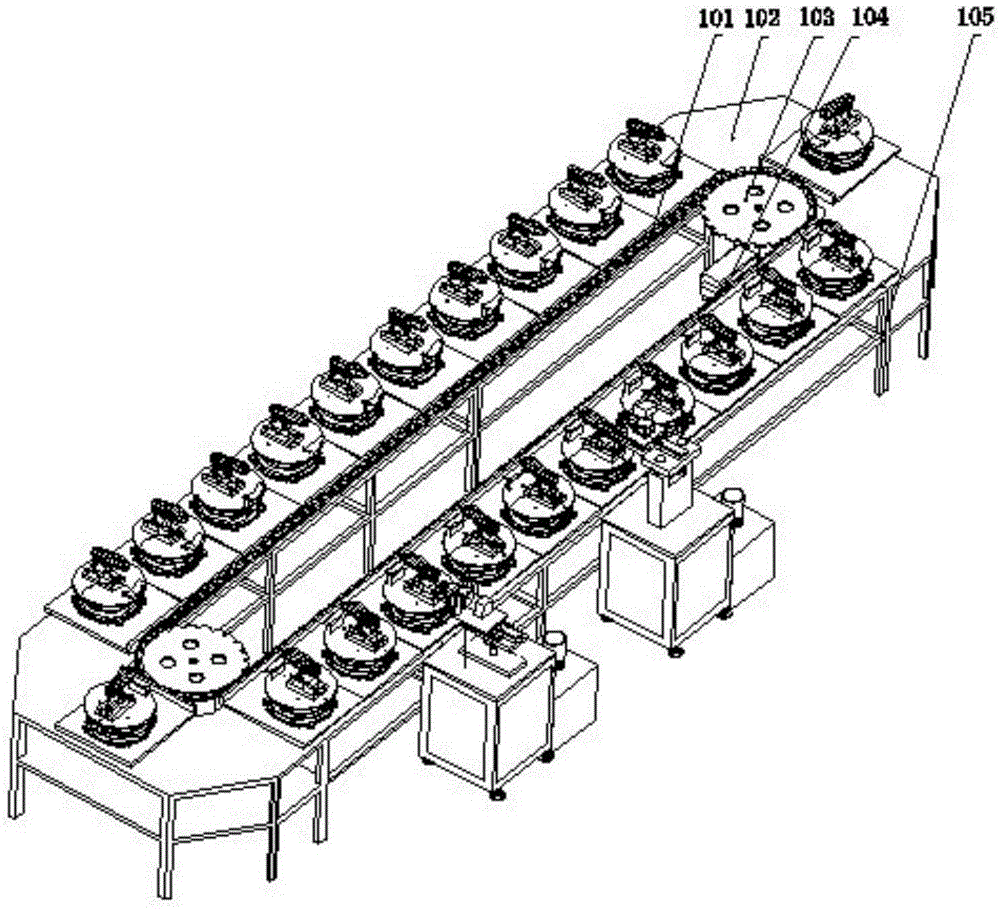

[0046] A multi-station assembly line type shoe upper raising system, comprising an annular transmission mechanism 1, a tray rotating mechanism 3, a Baotou raising machine 4, a dust collection device 5 and a rotary raising machine 6, and the upper radial direction of the annular transmission mechanism is evenly distributed. A plurality of tray rotating mechanisms, each tray rotating mechanism can be limitedly installed with a shoe last 2 for processing; a rotary raising machine 6 and a Baotou raising machine 4 are arranged at intervals on the outer circumference of the ring transmission mechanism, and the rotary raising machine The upper end of the Baotou raising machine is respectively equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com