An absorbable mesh reinforced interface screw and its preparation method

An interface screw and mesh technology, applied in the field of mesh-enhanced interface screws and their preparation, can solve the problems of weakening and decreasing the fixation strength of interface screws, and achieve the effects of avoiding inflammation, avoiding direct cutting, and reducing the risk of clinical use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

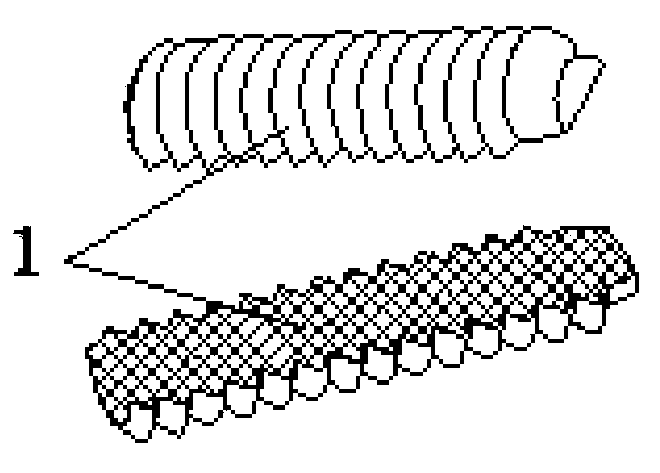

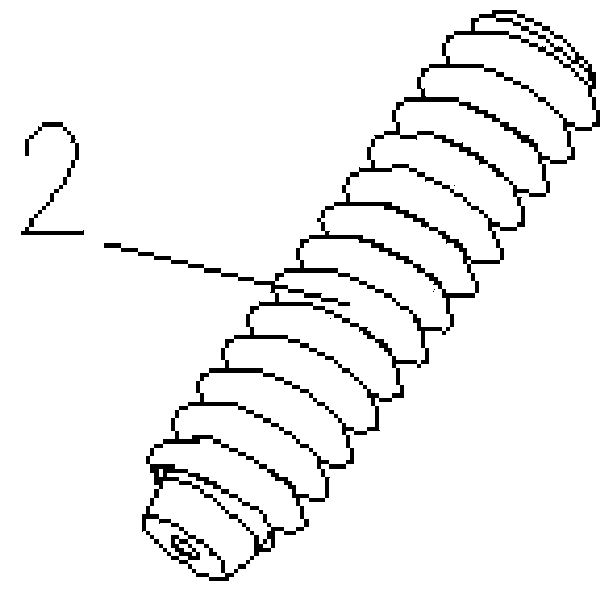

[0055] An absorbable interface screw with reticular reinforcement, which includes an absorbable interface screw and a reticular reinforcing material, the absorbable interface screw is wrapped in the reticular reinforcing material, and the absorbable interface screw consists of the following mass fraction The components are blended: 55-90% of the matrix material, 10-45% of the composite material, the matrix material is polylactic acid, the composite material is an inorganic component or an organic component, and the inorganic component is bioceramic or bioglass ; The reticular reinforcing material is blended with the following components in mass fraction: polylactic acid 50-96%, polylactic acid isomers 4-50%.

[0056] The polylactic acid is L-polylactic acid (PLLA) with a molecular weight of 200,000, the inorganic component is hydroxyapatite, and the polylactic acid isomer is racemic polylactic acid (PDLLA).

[0057] A method for preparing an absorbable mesh reinforced interfac...

Embodiment 2

[0064] An absorbable interface screw with reticular reinforcement, which includes an absorbable interface screw and a reticular reinforcing material, the absorbable interface screw is wrapped in the reticular reinforcing material, and the absorbable interface screw consists of the following mass fraction The components are blended: 80% of the matrix material, 20% of the composite material, the matrix material is polylactic acid, the composite material is an inorganic component or an organic component, and the inorganic component is bioceramic or bioglass; the mesh The shape reinforcing material is blended by the following components in mass fraction: polylactic acid 70%, polylactic acid isomer 30%.

[0065] The polylactic acid is L-polylactic acid (PLLA) with a molecular weight of 500,000, the inorganic component is hydroxyapatite, and the polylactic acid isomer is racemic polylactic acid (PDLLA).

[0066] A method for preparing an absorbable mesh reinforced interface screw, c...

Embodiment 3

[0072] 1) 75% (w / w) polylactic acid PLLA and 25% tricalcium phosphate TCP were uniformly mixed after drying, melted and blended by single-screw equipment at a temperature of 195°C, and injection-molded to obtain a polylactic acid-based interface screw;

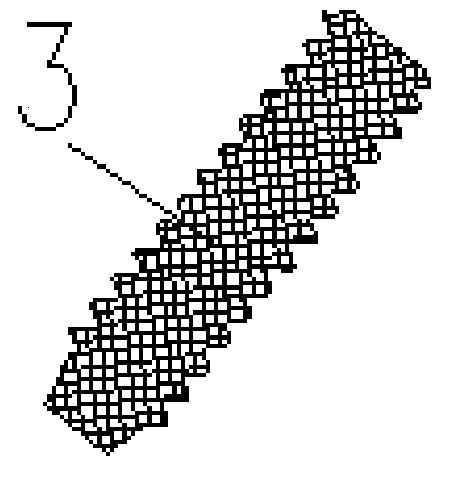

[0073] 2) Mix 80% (w / w) polylactic acid PLLA and 20% D,L-polylactic acid PDLLA after drying, melt spinning at 225-235°C, spinning speed 7km / min, drawing The stretch ratio is 7.5. The prepared polylactic acid fibers are heat-set, cooled and solidified, and then passed through micro-weaving equipment to weave into a network structure with a mesh diameter of 0.1 μm;

[0074] 3) Molding the polylactic acid mesh into the size and shape consistent with the interface screws;

[0075] 4) The three-dimensional special-shaped mesh is heat-bonded with the interface screw through a heat-sealing process, and the heat-sealing temperature is 70° C., thereby preparing an absorbable mesh-shaped reinforced interface screw.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com