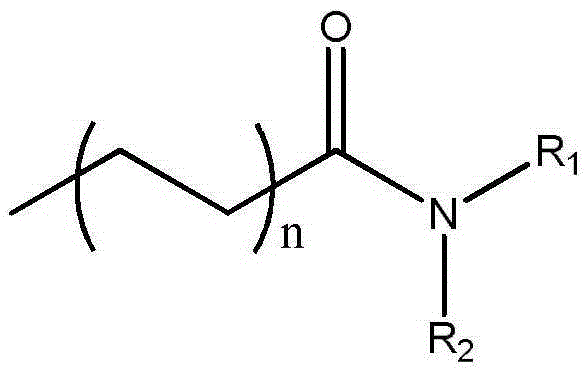

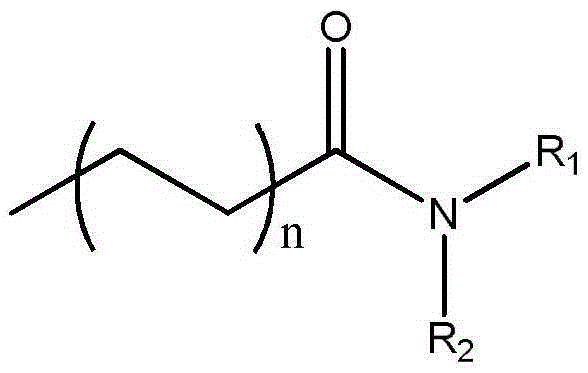

Reinforcing steel bar corrosion inhibitor of alkanolamide series and preparation method and application of reinforcing steel bar corrosion inhibitor

A technology of steel bar rust inhibitor and alkanolamide, applied in the field of steel bar rust inhibitor and alkanolamide type steel bar rust inhibitor, can solve the problem of high application cost, achieve convenient implementation, reduce electron transfer, and inhibit redox reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 284g of stearic acid and 1000g of xylene into the reaction kettle, stir evenly, add 120g of diethanolamine, add 8g of 4-dimethylaminopyridine, heat up to 140°C, and react for 10h to obtain a crude rust inhibitor product. Negative pressure distillation reclaims solvent xylene to obtain the novel rust inhibitor for steel bars.

Embodiment 2

[0029] Add 200g of lauric acid and 1200g of toluene into the reaction kettle, stir evenly, add 266g of diisopropanolamine, add 15g of 1-hydroxybenzotriazole, raise the temperature to 110°C, and react for 12 hours to obtain the crude rust inhibitor product. Negative pressure distillation reclaims the solvent toluene to obtain the novel rust inhibitor for steel bars.

Embodiment 3

[0031] Add 200g octanoic acid and 1000g tetrahydrofuran to the reaction kettle, stir evenly, add 140g ethanolamine, add 3.4g 2-(7-azobenzotriazole)-N,N,N',N'-tetramethyluronium hexafluoro Phosphate ester and 3.4 g of benzotriazol-1-yloxytris(dimethylamino)phosphonium hexafluorophosphate were heated up to 70° C. and reacted for 6 hours to obtain a crude rust inhibitor product. Negative pressure distillation reclaims the solvent toluene to obtain the novel rust inhibitor for steel bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com