Mixed additive for electrolytic alkaline etching waste liquid and method for preparing copper powder with it

A technology of mixing additives and etching waste liquid, applied in the field of additives in the electrolysis process, can solve the problems of high production cost, corroded equipment, unsuitable use, etc., and achieves the effects of stable product quality, simple production process and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

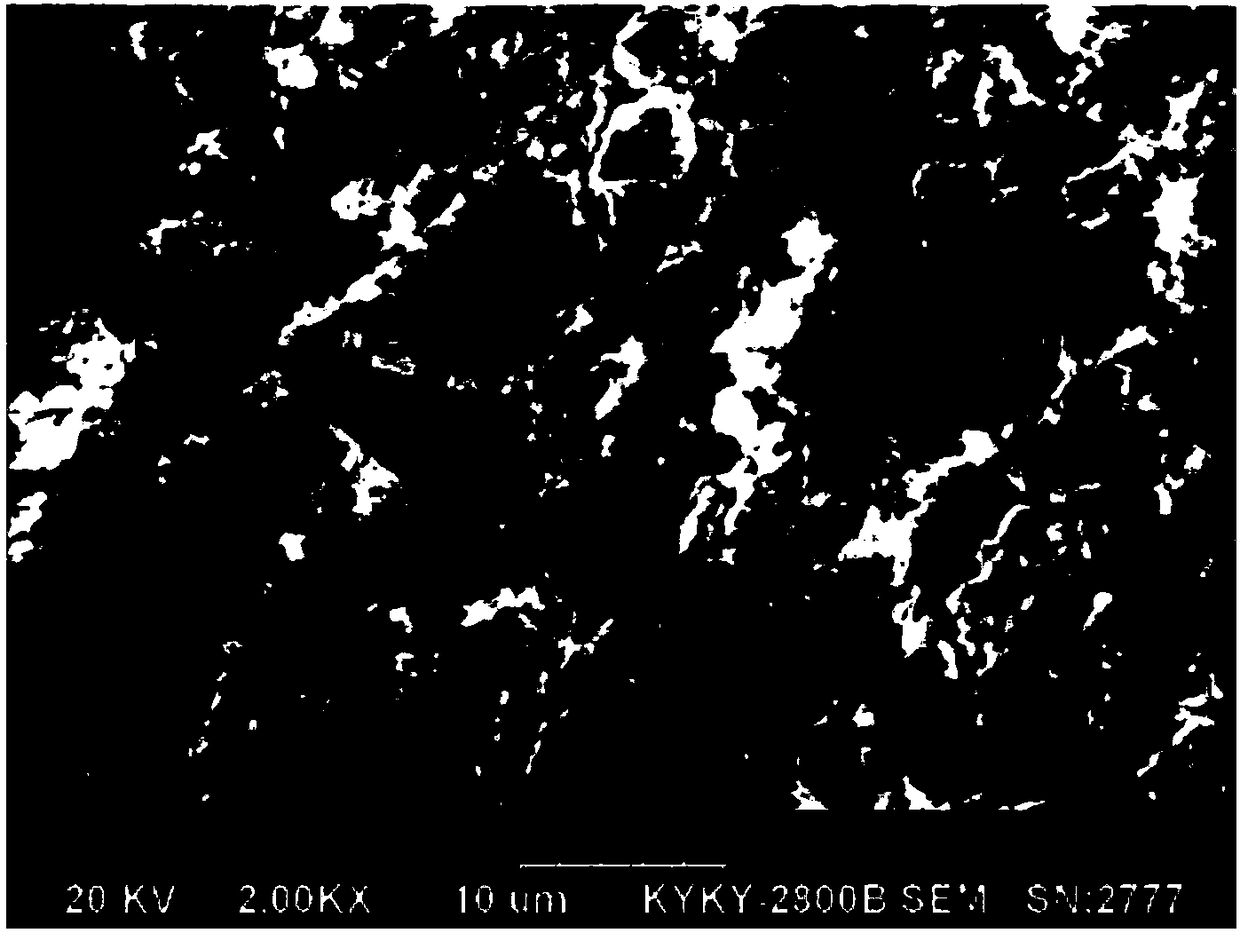

Image

Examples

Embodiment 1

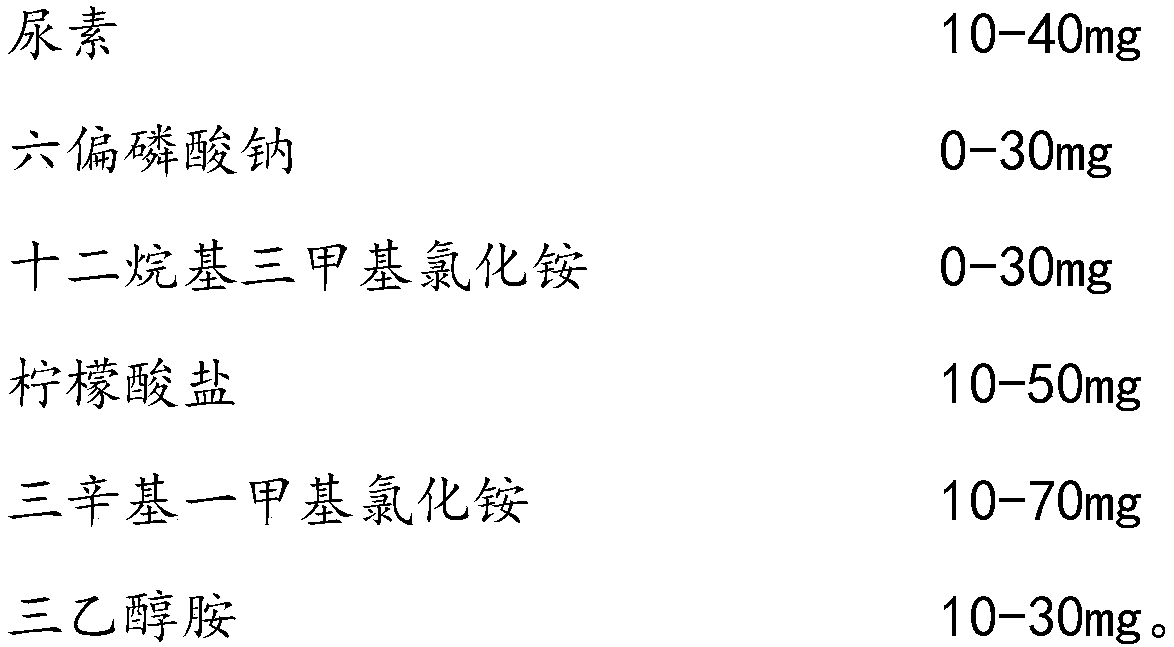

[0034] A mixed additive for electrolytic alkaline etching waste liquid, containing the following components in every liter of the aqueous solution of the mixed additive:

[0035]

[0036]

[0037] The method for preparing copper powder by using the above-mentioned mixed additives to electrolyze alkaline etching waste liquid, the operation steps are:

[0038] 1) Microporous precision filtration is carried out to the etching waste liquid, and the copper ion concentration of the obtained solution is 140g / L;

[0039] 2) Dilute the filtered etching waste liquid, add water until the copper ion concentration is 35g / L, add 55ml / L of mixed additives, and make an electrolyte;

[0040] 3) The electrolyte is pumped into the electrolytic cell, the nickel-based active coating electrode is used as the anode, and the stainless steel plate electrode is used as the cathode for direct electrolytic treatment. The temperature of the electrolyte is 45±2°C, and the current density is 1000A / m ...

Embodiment 2

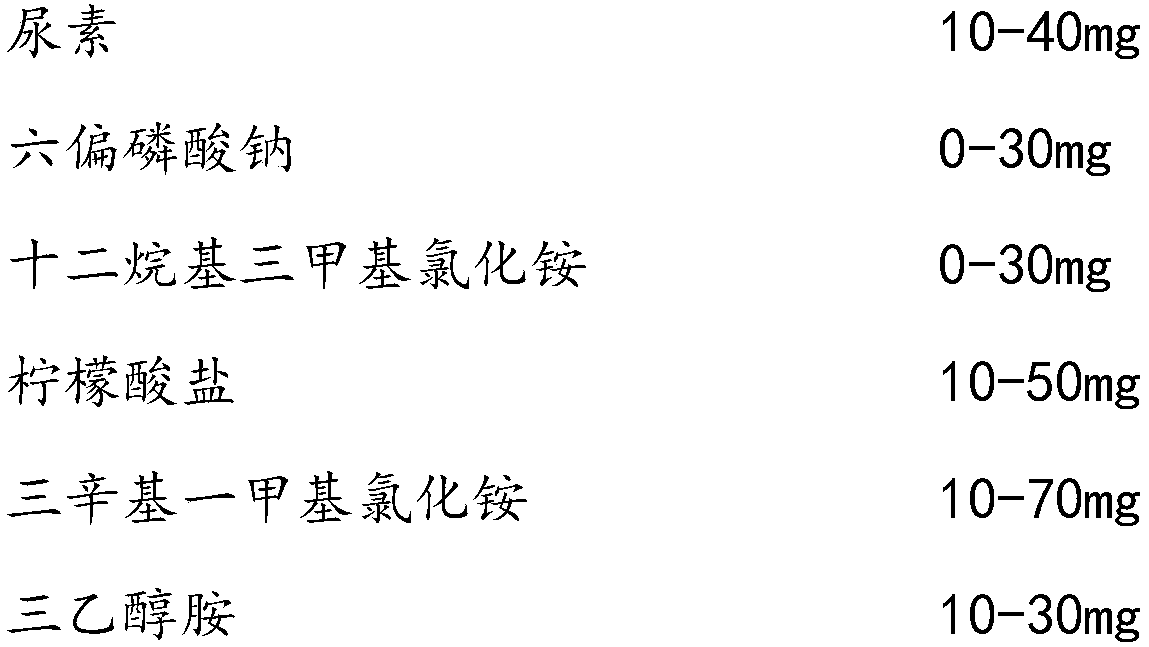

[0044] A mixed additive for electrolytic alkaline etching waste liquid, containing the following components in every liter of the aqueous solution of the mixed additive:

[0045]

[0046] The method for preparing copper powder by using the above-mentioned mixed additives to electrolyze alkaline etching waste liquid, the operation steps are:

[0047] 1) Microporous precision filtration is carried out to the etching waste liquid, and the copper ion concentration of the obtained solution is 120g / L;

[0048] 2) Dilute the filtered etching waste liquid, add water until the copper ion concentration is 40g / L, add 100ml / L of mixed additives, and make an electrolyte;

[0049] 3) The electrolyte is pumped into the electrolytic cell, and the titanium-based manganese dioxide electrode is used as the anode, and the stainless steel plate electrode is used as the cathode for direct electrolytic treatment. The temperature of the electrolyte is 30±2°C, and the current density is 1300A / m 2 ...

Embodiment 3

[0053] A mixed additive for electrolytic alkaline etching waste liquid, containing the following components in every liter of the aqueous solution of the mixed additive:

[0054]

[0055] The method for preparing copper powder by using the above-mentioned mixed additives to electrolyze alkaline etching waste liquid, the operation steps are:

[0056]1) Microporous precision filtration is carried out to the etching waste liquid, and the copper ion concentration of the obtained solution is 180g / L;

[0057] 2) Dilute the filtered etching waste liquid, add water until the copper ion concentration is 30g / L, add 80ml / L of mixed additives, and make an electrolyte;

[0058] 3) Pump the electrolyte into the electrolytic cell, use the titanium-based iridium coating electrode as the anode, and the stainless steel plate electrode as the cathode for direct electrolytic treatment. The temperature of the electrolyte is 53±2°C, and the current density is 800A / m 2 ;

[0059] 4) Peel off an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com