Method for producing light-weight novel wall body material through detritus mixing and steam curing

A wall material, steam curing technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of low product strength, transportation fracture, product cracking, etc., and achieve increased strength and bending resistance. , the effect of reducing low strength and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

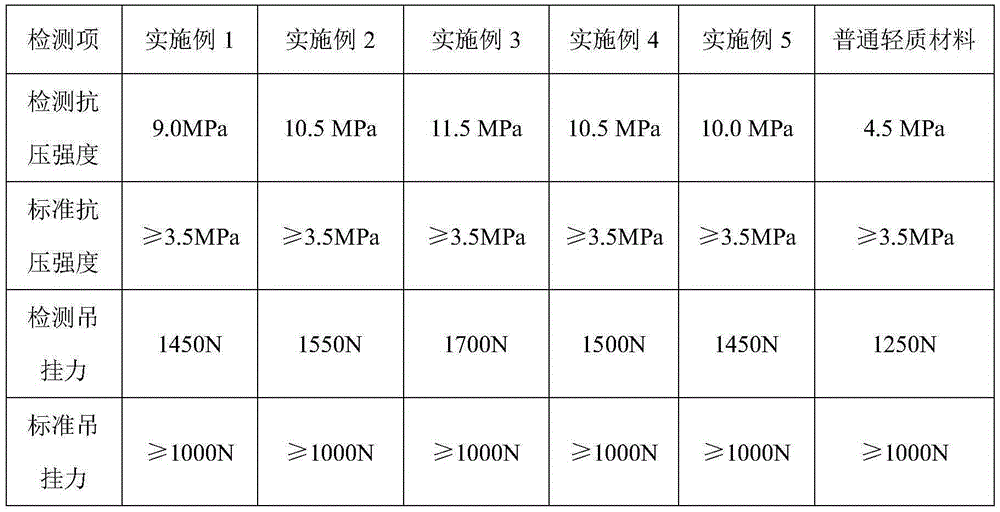

Examples

Embodiment 1

[0014] A method for producing a lightweight strip for construction with a length of 3000mm, a plate thickness of 100mm, and a core hole of 60mm, comprising the following steps:

[0015] (1) pulverize the coal cinder, the particle size is 0.2-2mm, and set aside;

[0016] (2) After crushing the gravel, clean it up, the particle size is 2-5mm, and set it aside;

[0017] (3) Stir the raw materials evenly to obtain concrete. The amount of raw materials per cubic meter of concrete is as follows: the raw materials include 300kg of cement, 900kg of coal cinder, 100kg of fly ash, 100kg of crushed stone, 75kg of ceramsite, 0.5kg of alkali-resistant fiber, water reducing 2kg of agent and 40kg of water; in order to achieve a balance between sufficient mixing and mixing energy consumption, and to reduce production costs as much as possible under the premise of ensuring quality, the concrete is mixed with a forced mixer, and the mixing time is 240s;

[0018] (4) Set up steel bars in the si...

Embodiment 2

[0020] A method for producing a light-weight batten for construction with a length of 3200mm, a plate thickness of 100mm, and a core hole of 60mm, comprising the following steps:

[0021] (1) pulverize the coal cinder, the particle size is 0.2-2mm, and set aside;

[0022] (2) After crushing the gravel, clean it up, the particle size is 2-5mm, and set it aside;

[0023] (3) Stir the raw materials evenly to obtain concrete. The amount of raw materials per cubic meter of concrete is: the raw materials include 320kg of cement, 850kg of coal cinder, 100kg of fly ash, 150kg of crushed stone, 75kg of ceramsite, 0.5kg of alkali-resistant fiber, water reducing 2kg of agent and 40kg of water; in order to achieve a balance between sufficient mixing and mixing energy consumption, and to reduce production costs as much as possible under the premise of ensuring quality, the concrete is mixed with a forced mixer, and the mixing time is 240s;

[0024] (4) Set up steel bars in the site where ...

Embodiment 3

[0026] The method for producing lightweight slats for construction with a length of 3000mm, a plate thickness of 100mm, and a core hole of 60mm comprises the following steps:

[0027] (1) pulverize the coal cinder, the particle size is 0.2-2mm, and set aside;

[0028] (2) After crushing the gravel, clean it up, the particle size is 2-5mm, and set it aside;

[0029] (3) Stir the raw materials evenly to obtain concrete. The amount of concrete raw materials used per cubic meter is: the raw materials include 360kg of cement, 800kg of coal cinder, 150kg of fly ash, 300kg of crushed stone, 75kg of ceramsite, 2kg of alkali-resistant fiber, and a water reducing agent. 2kg, water 50kg; in order to achieve a balance between sufficient mixing and mixing energy consumption, and reduce production costs as much as possible under the premise of ensuring quality, the concrete is mixed with a forced mixer, and the mixing time is 240s;

[0030] (4) Set up steel bars in the site where light wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com