A kind of superfine Portland cement-based grouting material and preparation method thereof

A Portland cement and grouting material technology, applied in the field of grouting reinforcement, can solve the problems of flammability, poor slurry stability, water loss, etc., and achieve the effects of improving hydrophobicity, low production cost, and improving water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An ultra-fine Portland cement-based grouting material. The formulation of the grouting material is: ultra-fine Portland cement clinker 7000g, ultra-fine fly ash 1500g, ultra-fine limestone powder 1500g, composite admixture 500g, Compound admixture 2 100g, tap water 5500g; Among them, compound admixture 1 formula is: expansion agent 550g, sodium sulfate 200g, sodium metaaluminate 200g, sodium gluconate 50g; compound admixture 2 formula is: thickening resin 50g, 150g of modified nano silica, 200g of polycarboxylic acid water reducer, and 600g of tap water.

[0021] Preparation:

[0022] In the first step, add 550g of expansion agent, 200g of sodium sulfate, 200g of sodium metaaluminate, and 50g of sodium gluconate into the mixer and mix evenly. After passing the test, compound additive one is obtained;

[0023] In the second step, add 50 g of thickening resin, 150 g of modified nano silica, 200 g of polycarboxylic acid water reducer, and 600 g of tap water to the mixer and mix ...

Embodiment 2

[0026] Example 2-different water-cement ratio

[0027] An ultra-fine Portland cement-based grouting material. The formulation of the grouting material is shown in Table 1. Among them, the formulations of the composite admixture 1 and the composite admixture 2 are the same as in Example 1.

[0028] Preparation method: The steps are the same as in Example 1, and the difference from Example 1 is that the amount of each raw material is weighed according to Table 1.

[0029] The properties of grouting materials obtained with different water-cement ratios are shown in Table 1.

[0030]

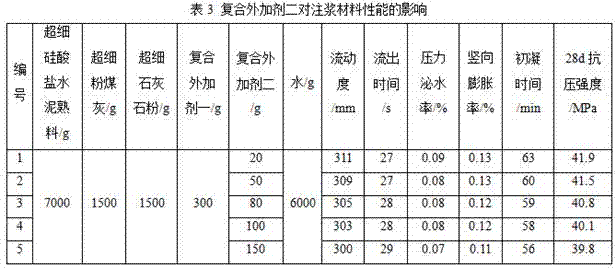

[0031] Example 3-A dosage of different composite admixtures

[0032] An ultra-fine Portland cement-based grouting material. The formulation of the grouting material is shown in Table 2; wherein, the formulations of the composite admixture 1 and the composite admixture 2 are the same as in Example 2.

[0033] Preparation method: The steps are the same as in Example 1, and the difference from Example 1 is that t...

Embodiment 4

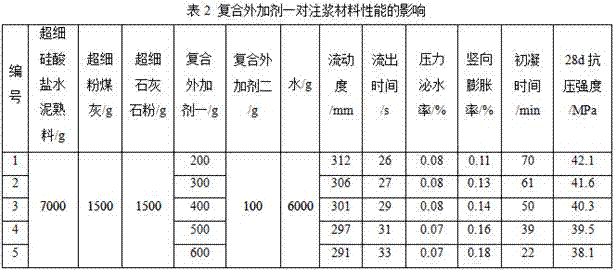

[0036] Example 4-Two dosages of different composite admixtures

[0037] An ultra-fine Portland cement-based grouting material. The formulation of the grouting material is shown in Table 3; wherein, the formulations of composite admixture 1 and composite admixture 2 are the same as in Example 3.

[0038] Preparation method: The steps are the same as in Example 1, and the difference from Example 1 is that the amount of each raw material is weighed according to Table 3.

[0039] See Table 3 for the performance of grouting material obtained with the two dosages of different compound admixtures.

[0040] Table 3 The influence of compound admixture 2 on the performance of grouting material

[0041]

[0042] In Examples 1-4: 1. Fluidity is carried out according to GB 50119-2003 Appendix A; 2. Outflow time is tested by Markov funnel; 3. Pressure bleeding rate is carried out according to GB / T 50080; 4. Vertical expansion rate Refer to GB 50119-2003 Appendix C; 5. Initial setting time GB / T 1346-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com