Preparation method and application of carbon nano tube modified carbon fiber enhanced SiBCN ceramic composite material

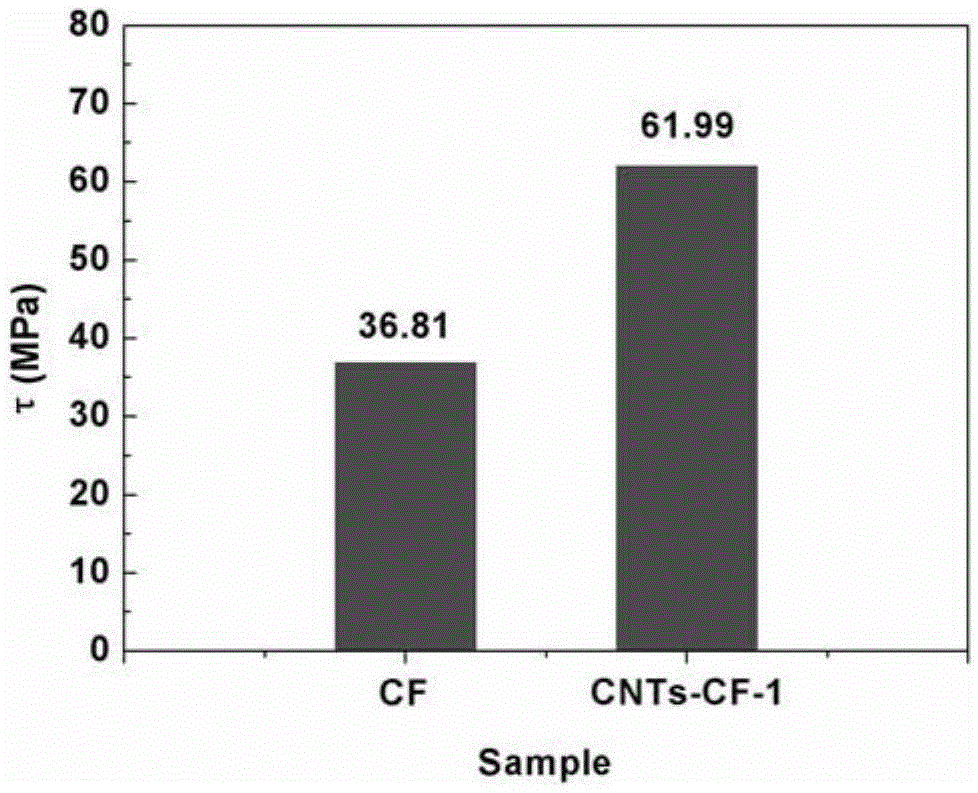

A technology of carbon nanotube modification and ceramic composite materials, which is applied in the field of preparation of SiBCN ceramic composite materials, can solve problems such as poor mechanical properties, achieve excellent high temperature resistance and mechanical properties, increase the bonding interface, and improve the interface bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

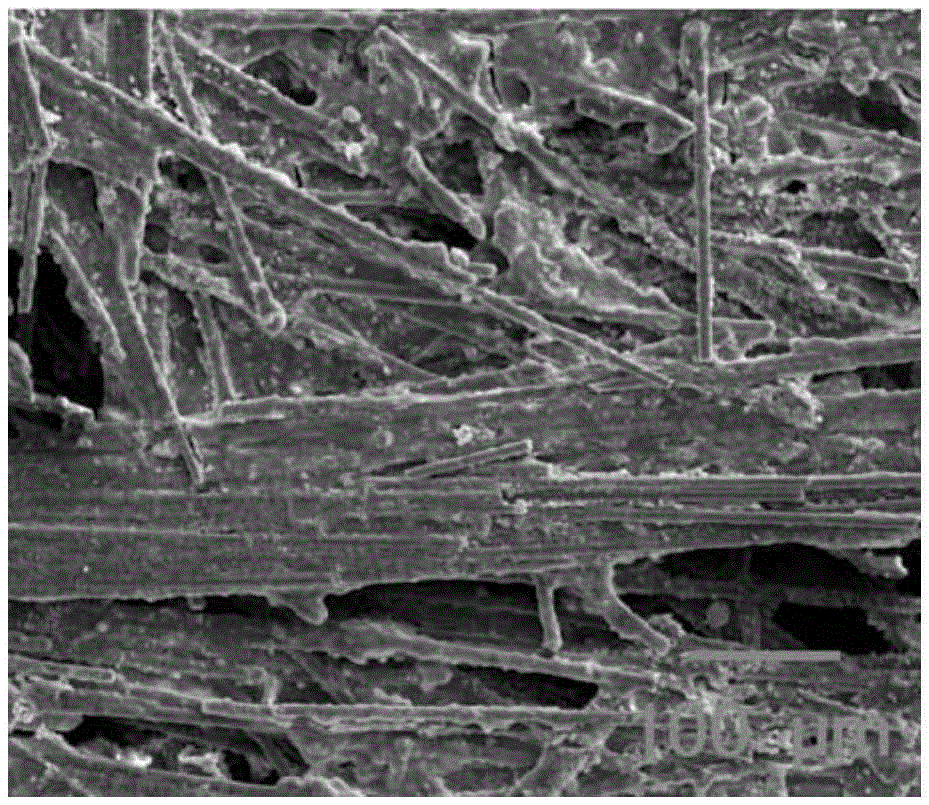

[0029] Specific embodiment one: the preparation method of carbon nanotube modified carbon fiber reinforced SiBCN ceramic composite material of this embodiment, carry out according to the following steps:

[0030] 1. Oxidize the surface of the carbon fiber to obtain oxidized carbon fiber;

[0031] 2. Attachment of the catalyst on the carbon fiber surface: Weigh the metal salt, prepare a 0.01-0.2mol / L metal salt acetone solution, immerse the oxidized carbon fiber obtained in step 1 into the metal salt acetone solution, and soak at room temperature for 10-15 hours , take out the soaked carbon fiber, put it in 50~60℃ and dry it for 12~14h;

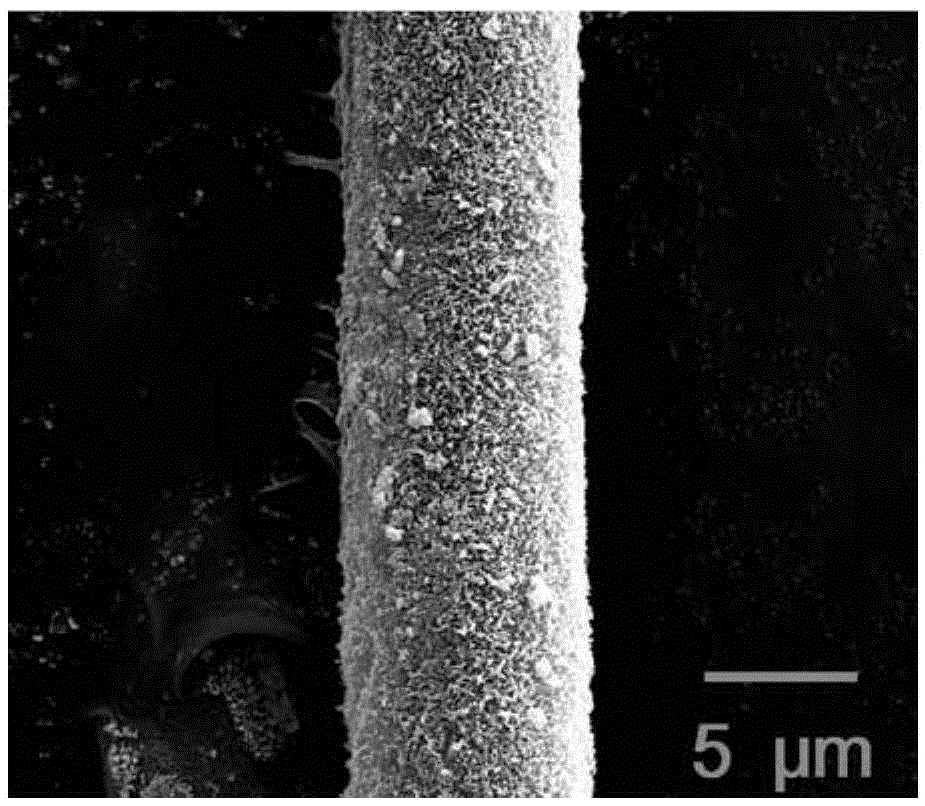

[0032] 3. Preparation of carbon nanotube modified carbon fiber reinforcement: carbon nanotubes are grown on the surface of carbon fiber with catalyst attached by plasma-enhanced chemical vapor deposition. Vacuum until the pressure in the furnace chamber is 0 Pa, and feed H at a flow rate of 20 sccm 2 , control the pressure in the furnace to ...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific method for oxidizing the surface of the carbon fiber in step 1 is: completely immerse the carbon fiber in acetone, and heat it at a temperature of 70-80°C. Reflux for 22-26 hours, dry at a temperature of 50-60°C for 12-14 hours to obtain dried carbon fibers, completely immerse the dried carbon fibers in concentrated nitric acid, soak at room temperature for 5-10 hours, take them out from the concentrated nitric acid, The carbon fibers are washed with deionized water until neutral, and dried at a temperature of 50-60° C. for 12-14 hours to obtain oxidized carbon fibers. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of concentrated nitric acid in step 1 is 65% to 75%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com