High-gloss anti-precipitation flame-retardant polypropylene material and preparation method thereof

A technology of flame-retardant polypropylene and microporous polypropylene, which is applied in the field of flame-retardant polypropylene, can solve the problems of low surface gloss of plastic products, wear of machine barrel and screw, and poor mechanical properties of materials, so as to avoid unstable material quality , not easy to raise dust, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

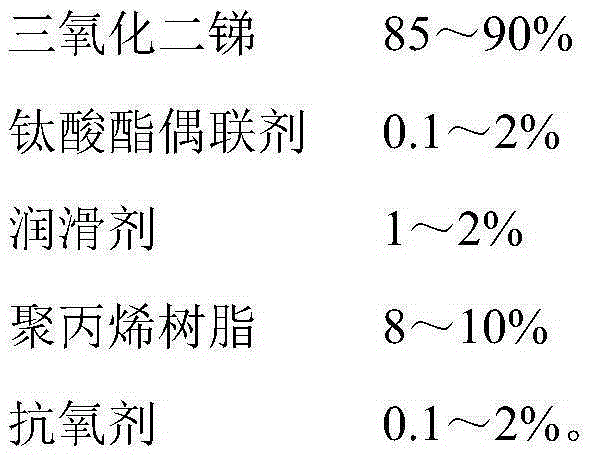

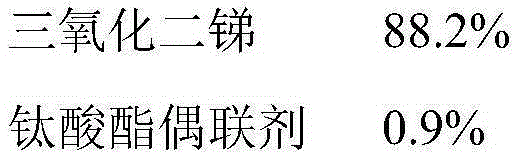

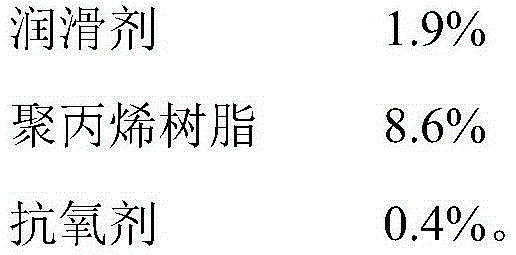

Method used

Image

Examples

Embodiment 1

[0042] Proportioning is carried out according to the following mass percentage composition: polypropylene resin (brand name: PPHJ4045, melt index (230 ℃, 2.16kg): 45g / 10min, Korean Petrochemical Company) 70%, octabromo-S ether masterbatch (used eight The model of bromine ether: FR640, Jiangsu Haohua Fine Chemical Co., Ltd.) 25%, antimony trioxide masterbatch (the antimony trioxide used is produced by Hunan Chenzhou Mining Co., Ltd.) 5%. The above materials are accurately weighed and stirred evenly.

Embodiment 2

[0055] Proportioning is carried out according to the following mass percentage composition: polypropylene resin (brand name: PPHJ4045, melt index (230 ℃, 2.16kg): 45g / 10min, Korean Petrochemical Company) 70%, octabromo-S ether masterbatch (used eight The model of bromine ether: FR640, Jiangsu Haohua Fine Chemical Co., Ltd.) 24%, antimony trioxide masterbatch (the antimony trioxide used is produced by Hunan Chenzhou Mining Co., Ltd.) 6%. The above materials are accurately weighed and stirred evenly.

Embodiment 3

[0057] Proportioning is carried out according to the following mass percentage composition: polypropylene resin (brand name: PPHJ4045, melt index (230 ℃, 2.16kg): 45g / 10min, Korean Petrochemical Company) 65%, octabromo-S ether masterbatch (used eight The model of bromine ether: FR640, Jiangsu Haohua Fine Chemical Co., Ltd.) 30%, antimony trioxide masterbatch (the antimony trioxide used is produced by Dongguan Jeff Flame Retardant Material Co., Ltd.) 5%. The above materials are accurately weighed and stirred evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com