Process for recycling high-purity gold from anode slime through organic reduction method

A technology of anode slime and reduction method, which is applied in the field of wet smelting production, can solve the problems of large consumption of aqua regia and hydrochloric acid solution, large production investment, etc., and achieve the effect of eliminating electrolysis process, saving production cost, and fast capital turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

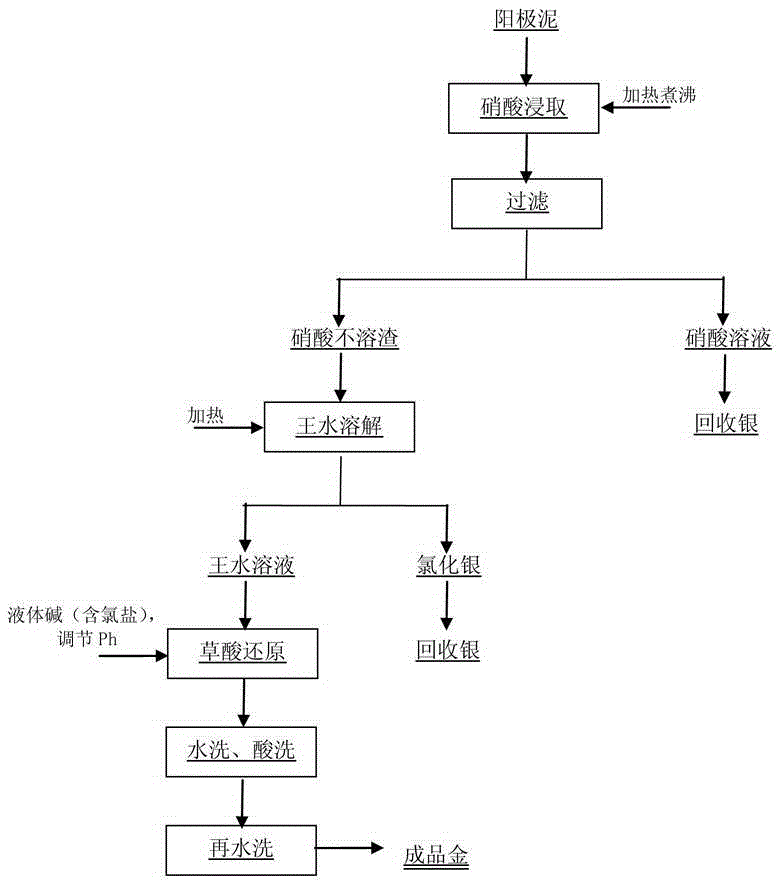

[0016] attached figure 1 Representing an organic reduction method to recover high-purity gold process steps from anode slime is:

[0017] ①Acid leaching to remove impurities

[0018] Before using aqua regia for gold, carry out acid leaching to remove impurities, leaching the anode slime with boiling nitric acid, and control the liquid-solid volume mass ratio of 10:1L / kg; let part of the oxides, hydroxides and soluble salts in the anode slime enter solution; avoid impurities entering the solution during the aqua regia gold process; filter and dry the nitric acid insoluble residue, and recover silver from the nitric acid washing solution;

[0019] ②Aqua regia soluble gold

[0020] Add aqua regia to the nitric acid insoluble slag, control the liquid-solid volume mass ratio 6:1L / kg; heat, and under the condition of 100 ℃, the gold in the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com