Oxide-dispersion-strengthened low-activation steel and preparation method thereof

A low-activation steel and dispersion strengthening technology, applied in the field of radiation-resistant metal materials, can solve the problems of high purity requirements of pure metal powder, difficult control of impurity content, and difficulty in preparing activated steel, so as to improve purity and density, Improving the high temperature mechanical properties and the effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The mechanical alloying method is used to prepare oxide dispersion strengthened low activation steel. The specific process parameters are as follows:

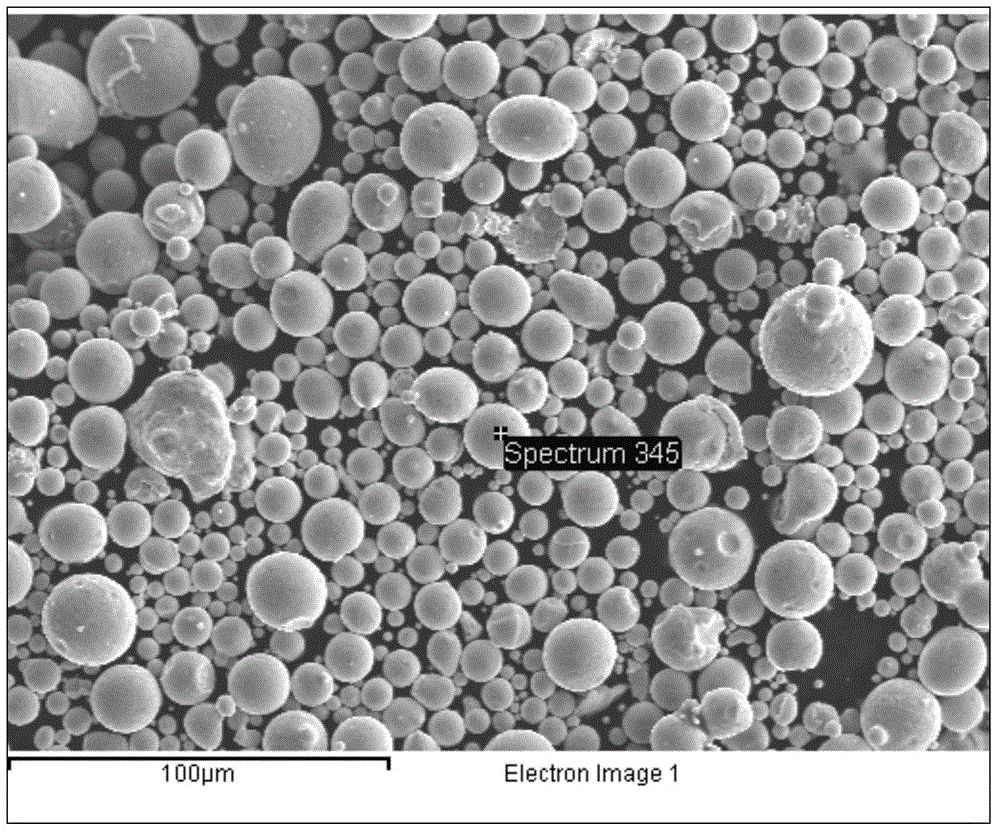

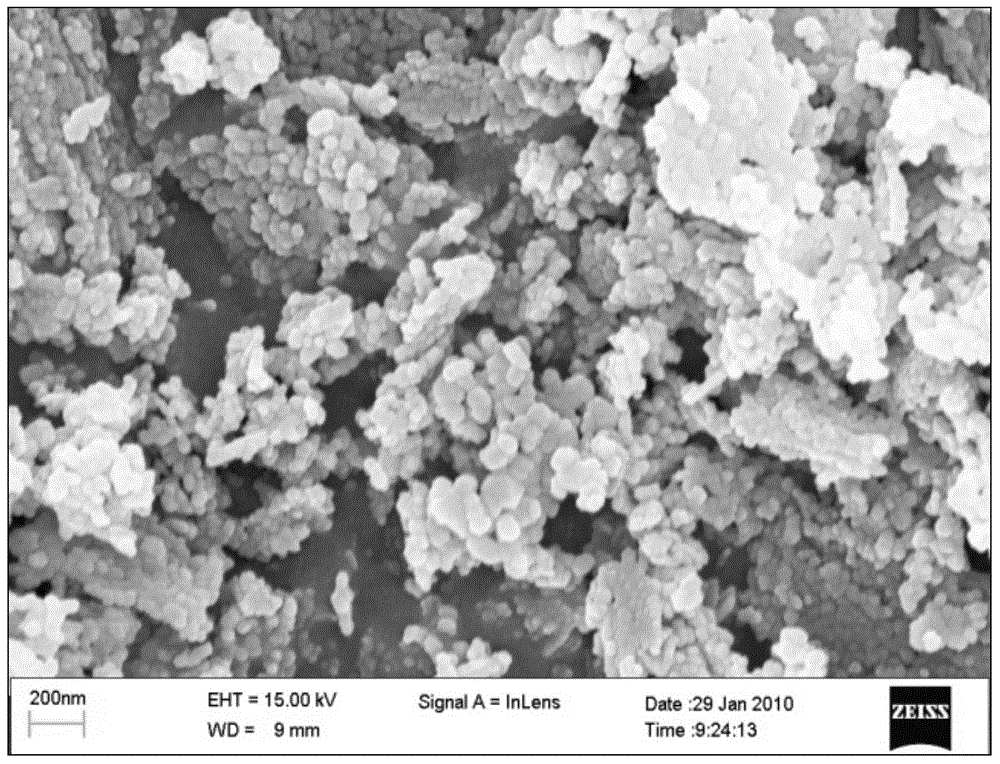

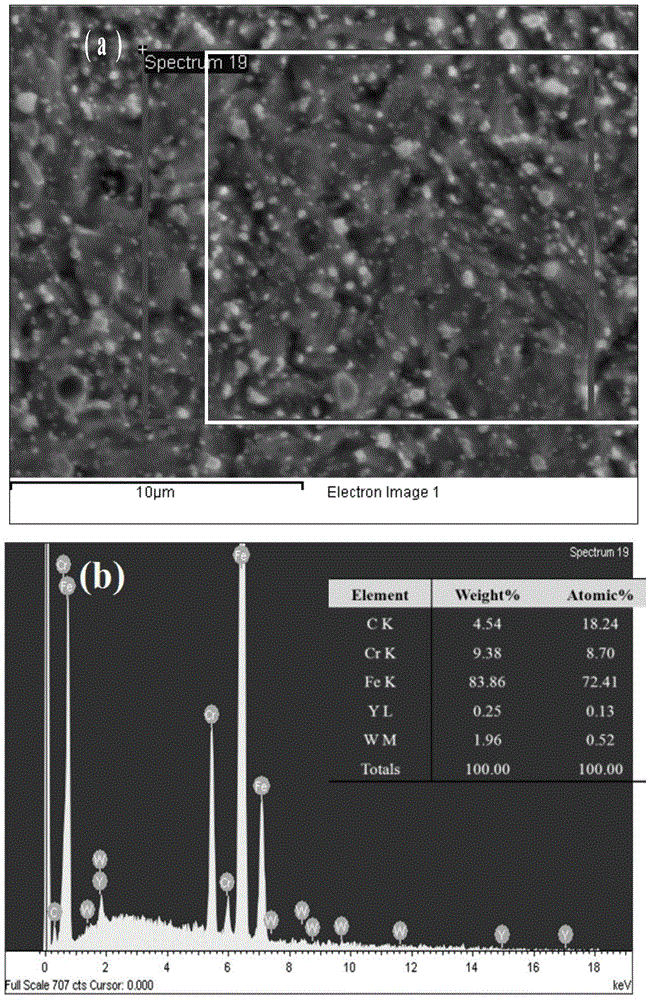

[0048] The chemical composition of the smelting master alloy is: C: 0.093wt.%, Cr: 8.96wt.%, W: 1.51wt.%, V: 0.20wt.%, Ta: 0.14wt.%, Mn: 0.51wt.% , Al 3.5Mpa, overheating degree> At 200°C, the protective atmosphere is 99.99% argon. Add 0.3% of nanometer Y to the master alloy atomized powder 2 O 3 After 50 hours of high-energy ball milling (the mass ratio of ball to material is 10:1, the ball milling medium is Φ6 and Φ10 mixed hard steel balls, and the ball milling atmosphere is 99.99% Ar), the powder is mixed uniformly, and the air is pumped through the powder jacket (10 -1 Pa / 450℃ / 4h) and hot isostatic pressing method sintered and solidified (1200℃ / 150MPa / 4h), and finally after hot rolling (open rolling at 1100℃, rolling 5 passes, the reduction of each pass is 18- 25%) and heat treatment (normalizing 980℃ / 60min / air coolin...

Embodiment 2

[0050] The difference from the preparation method in Example 1 is that 0.48% of nanometer Y is added to the master alloy atomized powder. 2 O 3 After 40 hours of high-energy ball milling (the ball-to-material mass ratio is 10:1, the ball milling medium is Φ6 and Φ10 mixed hard steel balls, the ball milling atmosphere is 99.99% Ar), the powder is mixed uniformly, and the air is pumped through the powder jacket (10 -1 Pa / 500℃ / 4h) and hot isostatic pressing method sintered and solidified (1200℃ / 120MPa / 3.5h), and finally after hot rolling (starting at 1200℃, rolling 6 passes, the reduction of each pass is 18 -25%) and heat treatment (normalizing 980°C / 60min / air cooling + tempering 760°C / 90min / air cooling) to obtain the final oxide dispersion strengthened low activation steel.

Embodiment 3

[0052] The difference from the preparation method of Example 1 is that 0.3% of nanometer Y is added to the atomized powder of the master alloy. 2 O 3 After 70h of high-energy ball milling (ball-to-battery ratio is 10:1, ball milling medium is Φ6 and Φ10 mixed hard steel balls, ball milling atmosphere is 99.99% Ar), the powder is mixed uniformly, and the air is pumped through the powder jacket (10 -1 Pa / 450℃ / 4h) and hot isostatic pressing method sintered and solidified (1100℃ / 140MPa / 3h), and finally undergoes hot rolling (1150℃ open rolling, rolling 5 passes, and the reduction of each pass is 18- 25%) and heat treatment (normalizing 980°C / 60min / air cooling + tempering 760°C / 90min / air cooling) to obtain the final oxide dispersion strengthened low activation steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com