Electrode and preparation method thereof

An electrode and conductive carbon technology, applied in the field of electrodes, can solve the problems of high resistance of conductive polymers, poor conductivity of polymers, and cannot be used as high-current electrolysis electrodes, etc., and achieve the effects of low price, improved conductivity, and protection of metal skeletons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Making a three-dimensional network metal skeleton

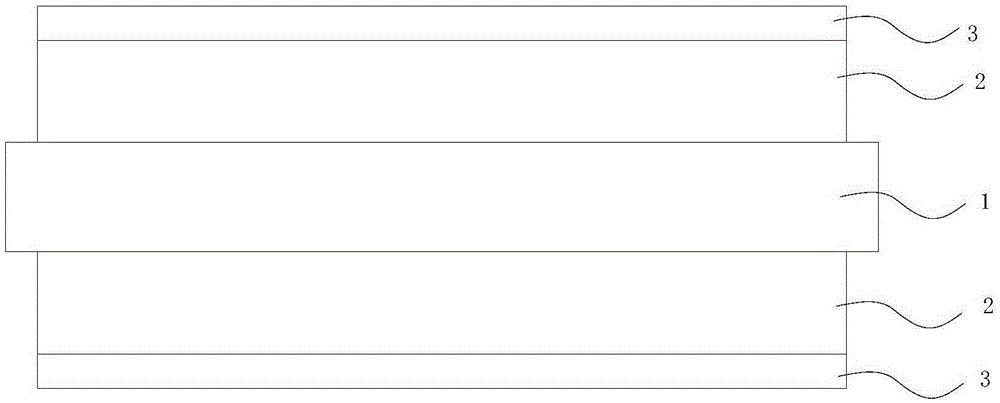

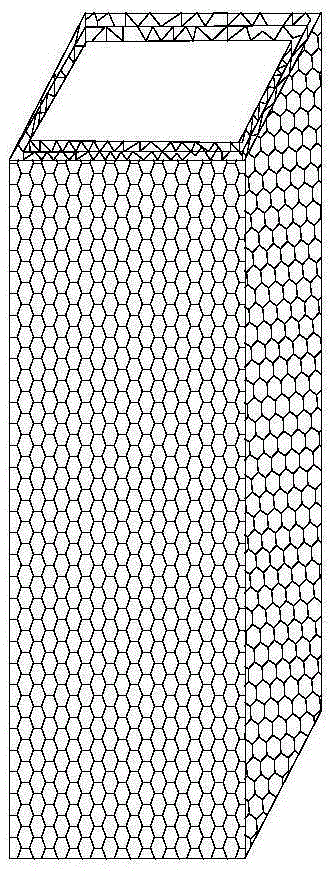

[0049] Take the metal mesh plate, the material is stainless steel, the plate thickness is 0.1mm, and the cut metal mesh plate is 15cm×24cm, and weld it into a 2.5cm×1.5cm×15cm cuboid (the cuboid has no bottom and top), such as figure 2 Shown. From figure 2 It can be seen that the three-dimensional network metal framework has a rectangular parallelepiped shape as a whole, including four faces, and each face is a three-layer metal mesh plate.

Embodiment 2

[0050] Example 2: Making a three-dimensional network metal skeleton containing conductive rods

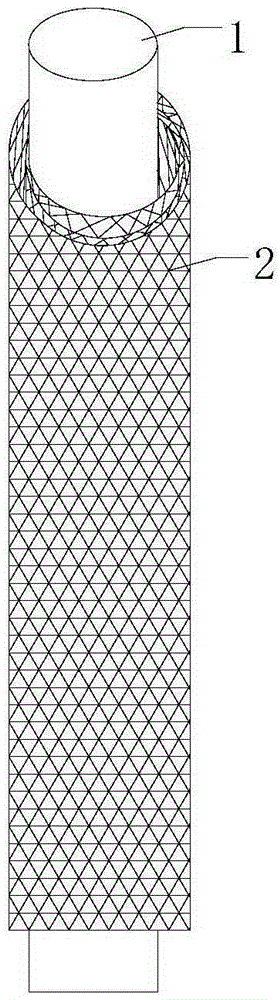

[0051] Take the metal mesh plate and the conductive rod, both made of titanium, the length of the conductive rod is 12cm, the diameter is 10mm, and the cut metal mesh is 10cm×10cm. Weld one side on the conductive rod and rotate the other side along the conductive rod to form a cylindrical shape. , The conductive rod is located in the center of the cylinder, the other side is welded to the surface of the cylinder, and the welding is carried out under argon protection, such as image 3 Shown. From image 3 It can be seen that the metal mesh plate is wound on the conductive rod, and the two ends of the conductive rod extend out of the three-dimensional network metal skeleton wound by the metal mesh plate.

Embodiment 3

[0052] Example 3: Fabrication of electrodes

[0053] Take a conductive rod with a length of 17 cm and a diameter of 12 mm, and insert it into the three-dimensional network metal framework in Example 1. According to the ratio of polyaniline: polyolefin: acetylene black mass ratio = 50:20:30, weigh the raw materials and mix them evenly, heat them to a molten state (acetylene black is in a suspended state), and then inject them until the conductive rod is placed In the mesh of the three-dimensional network metal skeleton, the conductive rod is located on the central axis of the three-dimensional network metal skeleton, and the electrode is obtained by cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com