Non-circular planetary gear hydraulic motor for oil-emulsion medium

A non-circular planetary gear and hydraulic motor technology, applied in the field of hydraulic components, can solve the problems of difficult installation and layout of the main engine, low volumetric mechanical efficiency, poor operation stability, etc., and achieve convenient installation and layout of the main engine, good explosion-proof safety performance, and anti- The effect of strong rust and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

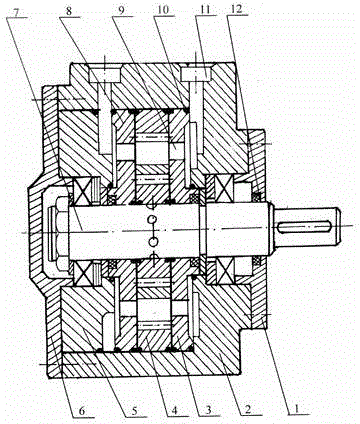

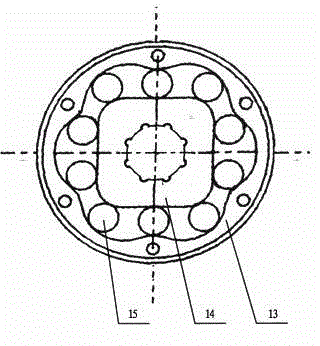

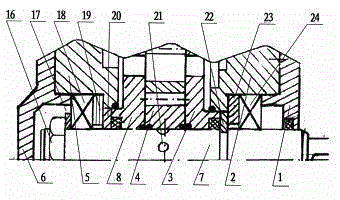

[0032] as attached figure 1 As shown, the general-purpose non-circular planetary gear hydraulic motor for oil emulsion medium researched and designed by the patent of the present invention includes motor housing, non-circular planetary gear mechanism (4), liquid distribution device, power output device, rubber sealing system and other main working parts.

[0033] as attached figure 1As shown, the motor casing is designed to be composed of motor casing (2), bottom end cover (6), front end gland (1) and other components, all of which are made of high-strength explosion-proof aluminum alloy castings. , to install and connect all the working parts of the hydraulic motor in an inclusive manner; the motor housing (2) is provided with two inlet and outlet pipes (11) on the left and right, which are respectively connected to the configured hydraulic reversing valve through hydraulic hoses to introduce or discharge pressure liquid. On the inner wall of the motor housing (2), the hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com