Oil-furnace-heat-supply type dryer

A technology for dryers and oil furnaces, applied in the field of dryers, which can solve the problems of non-compliance with energy conservation and environmental protection, steam discharge, and failure to use waste heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

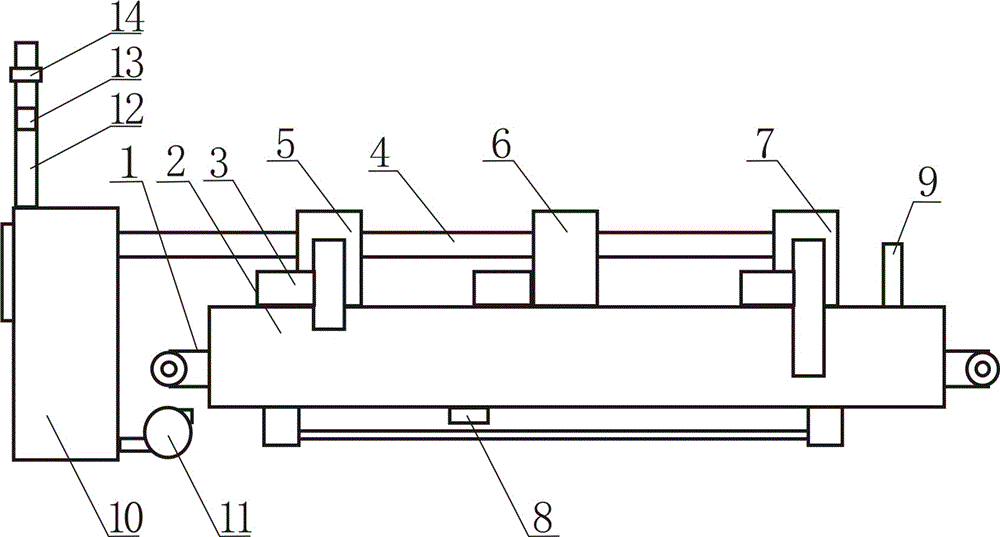

[0022] Such as figure 1 As shown, the oil furnace heating type dryer includes a drying bin 2, an oil furnace heating device and a conveying mesh belt 1, and the conveying mesh belt 1 is arranged in the drying chamber 2, and the oil furnace heating device includes The heat exchanger 5, the heat exchanger 6, the heat exchanger 7, the hot oil conduit 4 and the oil furnace 10 are formed, and the heat exchanger 5, the heat exchanger 6 and the heat exchanger 7 are distributed in the drying chamber 2 at intervals, and a plurality of The heat exchanger 5 constitutes a hot oil circulation channel through the hot oil conduit 4 and the oil furnace.

[0023] A smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com