Method for manufacturing silicon dioxide microlens

A technology of silicon dioxide and manufacturing methods, applied in the fields of lenses, optics, instruments, etc., which can solve problems such as unsuitable for mass production, high cost, and lens surface distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In this embodiment, N=3 is taken as an example for illustration.

[0054] Such as Figure 1-8 Shown, a kind of manufacture method of silica microlens, the steps are as follows:

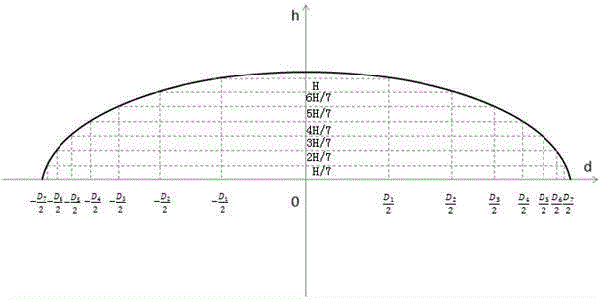

[0055] Step S1: Determine the lens height H of the microlens and the number of photolithography N, then the lens height of the microlens is equally divided into 2 N -1 copy.

[0056] Wherein, the number of times of photolithography N=3, then the lens height of the microlens is equally divided into 2 N -1 = 7 copies.

[0057] Step S2: According to the distance between the horizontal line of the lens height H at each equal height and the two intersection points of the microlens surface characteristic function, determine the cylinder diameters at the corresponding heights in the coaxial cylinder stack structure, respectively D 1 、D 2 、D 3 、D 4 、D 5 、D 6 and D 7 .

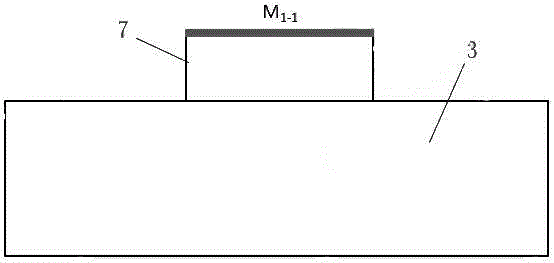

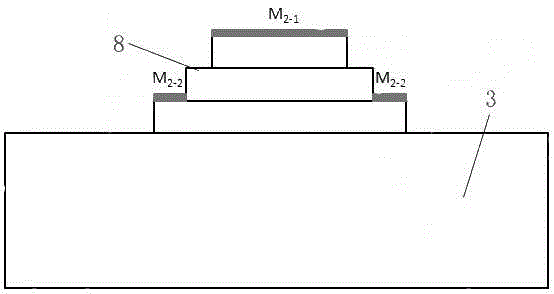

[0058] Step S3: According to the calculation result in step S2, calculate the mask layer M to be formed before the N-n phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com