Hawksbill fancy glaze and firing method thereof

A technology of tortoiseshell and flower glaze, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of small yellow-brown area on the surface of the glaze body, poor appreciation of porcelain appearance, and inconspicuous characteristics of tortoiseshell patterns, etc., to achieve distinctive features, vivid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

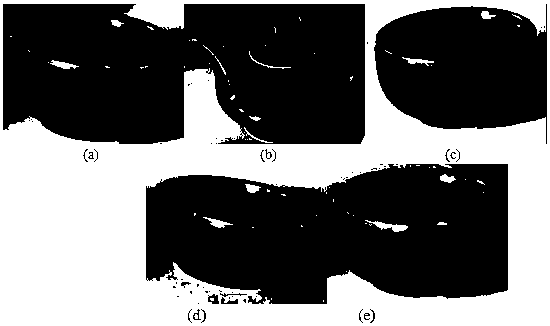

Image

Examples

Embodiment 1

[0039] A tortoiseshell flower glaze, which is composed of a bottom glaze and a top glaze, the components in the bottom glaze are respectively by weight: 57 parts of potassium feldspar, 16 parts of quartz, 8 parts of limestone, 2 parts of talc, and 8 parts of ball soil , 2 parts of ashes, 7 parts of ferric oxide; the components in the surface glaze are respectively by weight: 55 parts of feldspar, 8 parts of quartz, 18 parts of limestone, 4.5 parts of talc, 10 parts of ball clay, purple gold clay 4.4 parts, 0.1 part of hydroxyethyl cellulose;

[0040] Wherein, ferric oxide is through modified treatment, and the method of described modified treatment is:

[0041] Step 1, configure the modified solution, the modified solution is an ethanol solution of isobutyltriethoxysilane, tetrabutyl titanate and citric acid, the mass percentage of the isobutyltriethoxysilane in the solution 10%, the mass percentage of tetrabutyl titanate is 5%, and the mass percentage of citric acid is 1%; ...

Embodiment 2

[0055] A tortoiseshell flower glaze, which is composed of a bottom glaze and a top glaze, and the components in the bottom glaze are respectively by weight: 58 parts of potassium feldspar, 20 parts of quartz, 10 parts of limestone, 2.5 parts of talc, and 6 parts of ball soil , 1 part of ashes, 7.5 parts of ferric oxide; the components in the surface glaze are respectively by weight: 58 parts of feldspar, 12 parts of quartz, 21 parts of limestone, 3 parts of talc, 14 parts of ball clay, purple gold clay 5 parts, 0.2 parts of hydroxyethyl cellulose;

[0056] Wherein, ferric oxide is through modified treatment, and the method of described modified treatment is:

[0057] Step 1, configure the modified solution, the modified solution is an ethanol solution of isobutyl triethoxysilane, tetrabutyl titanate and citric acid, the isobutyl triethoxysilane, titanic acid The mass percentages of tetrabutyl ester and citric acid are respectively 17%, 6% and 3%;

[0058] Step 2, soak the fe...

Embodiment 3

[0070] A tortoiseshell flower glaze, which is composed of a bottom glaze and a top glaze, the components in the bottom glaze are respectively by weight: 63 parts of feldspar, 25 parts of quartz, 15 parts of limestone, 5 parts of talc, 5 parts of ball soil, 1 part of bone ash, 8 parts of ferric oxide; the components in the surface glaze are respectively by weight: 60 parts of feldspar, 16 parts of quartz, 21 parts of limestone, 9 parts of talc, 16 parts of ball clay, 3 parts of purple gold clay part, 0.1 part of hydroxyethyl cellulose;

[0071] Wherein, ferric oxide is through modified treatment, and the method of described modified treatment is:

[0072] Step 1, configure the modified solution, the modified solution is an ethanol solution of isobutyl triethoxysilane, tetrabutyl titanate and citric acid, the isobutyl triethoxysilane, titanic acid The mass percentages of tetrabutyl ester and citric acid are respectively 20%, 7% and 4%;

[0073] Step 2, soak the ferric oxide po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com